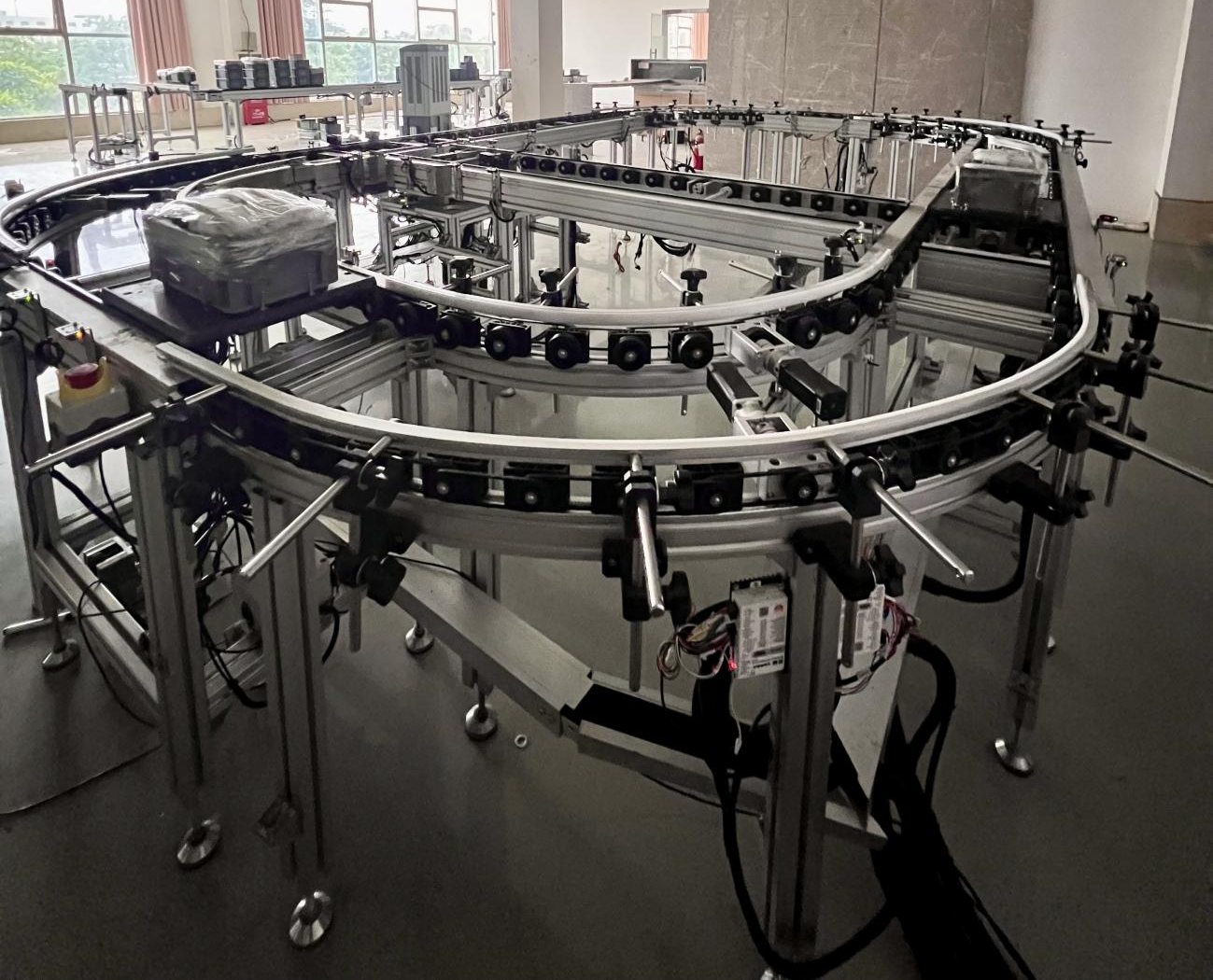

In the lithium and other production beat and cleanliness requirements of the industry, the choice of conveyor line directly affects the production capacity and product quality. Today's introduction of thisHigh-speed roller conveyor lineThe company's strength is to stand out in a crowd of conveying equipment, and compared with the ordinary conveying line, what advantages it has?

One,High-speed roller conveyor line

High-speed roller lineWith rubber-coated rollers as the transfer medium, it is extremely flexible in terms of specifications and performance:

- Size:Tray width can be 240, 320, 400, 480, 640mm, length can be 320, 400, 480, 640mm, wire length can be 600, 1000, 1500mm, all specifications support non-standard customization, can accurately adapt to the size of different scenes;

- Speed:Rated speed up to 60, 80m/min (support customized higher speed), up to 2 meters per second conveying efficiency, perfect match with high beat production;

- Load:Allow a maximum load of 15Kg (support customization), with direct motor drive, voltage adapted to 220/380AC, practicality and stability at the same time.

Two,dominance

High-speed roller lineThe advantage is by no means one-dimensional, but rather a multifaceted descending blow:

High-speed beats:With a conveying speed of 2 meters per second, it directly hits the lithium-ion battery core assembly section and other high-tempo just-demand scenarios, solving the capacity bottleneck;

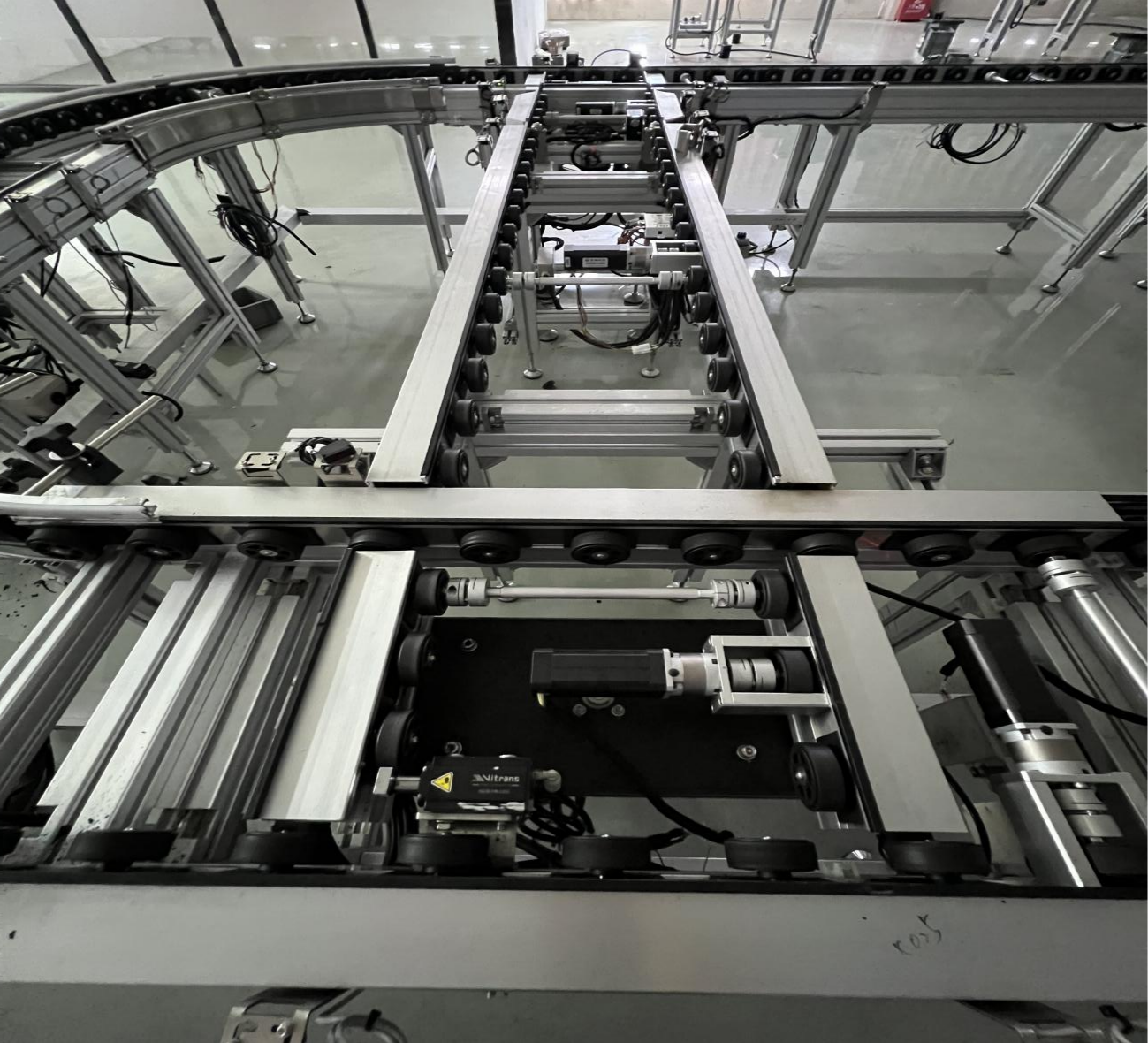

Clean and low dust:Relying on roller rolling conveyor, no dust pollution generated by belt friction, can meet the stringent requirements of the lithium industry more than 10,000 clean room, cleanliness-sensitive production scenarios (such as)Precision electronics) can also be easily adapted;

Wear-resistant and stable:The wheels and the bottom of the tray are made of high wear-resistant material, together with Wei Chuang's product concept of full-load life testing (any changes in parts are simulated by customers to repeatedly verify the working conditions), the durability of the pulling full, significantly reducing maintenance costs;

High-precision Positioning:It can be equipped with magnetic levitation drive module to realize the positioning accuracy of silk level or above, and it can be accurately in place at the same time of high-speed conveying, so it is suitable for the work processes that have strict requirements on positioning;

Wide adaptability:From size, speed to load, all of them can be personalized according to the demand, completely getting rid of the trouble of non-standard scenes can not be adapted.

Three,comparisonGeneral Conveyor Line

premise sth.belt conveyorAs an example.High-speed roller lineThe advantages of the comparison are clear at a glance:

| dominancecomparison | High-speed roller line | Ordinary belt line |

| Conveying speed | Up to 2 meters per second for high-tempo conveying | Slower speeds make it difficult to meet the demand for high speed capacity |

| cleanness | Frictionless dust, suitable for class 10,000 clean rooms | Belt friction easily generates dust and lack of cleanliness |

| Abrasion Resistance and Longevity | Wear-resistant material for durability | Belts are prone to wear and have a relatively short life |

| position accuracy | Can be used with magnetic levitation to achieve silk-level positioning | Lower positioning accuracy |

Four,be applicabletake

High-speed roller line在Lithium industryIt is tailor-made, especially for the assembly section of the battery cell, which has a double high demand for conveying speed + cleanliness, and it can undertake it perfectly.

In addition to this, but all areas involving high beat production, dust-free environments above class 10,000, and precision positioning processes, such as the production of high-end electronic components and the assembly of precision instruments, there areHigh-speed roller lineThe usefulness of the

summarize

high speedroller conveyorCrush the ordinary in all aspects of speed, cleanliness, abrasion resistance, positioning and other dimensions.conveying lineIn addition to the manufacturer's rigorous testing of product quality, choosing it is choosing high efficiency, stability and peace of mind. In the pursuit of production capacity and quality today, it is absolutely the right choice in the conveyor equipment!