The smooth running of the production line depends a lot on the smooth transportation of materials.doubled speed chainconveying lineIt is the key equipment responsible for material transportation in many factories, from small electronic parts to large assembled electrical appliances, all rely on it to move between different working positions. Today we will briefly talk aboutSpeed Chain Conveyor Linescenarios, and their common layout types.

One,Speed Chain Conveyor Linescenarios

Speed Chain Conveyor LineIt is common in factories and is mainly used in these usage scenarios:

①Connecting lines:The parts are made in the previous process and sent through it directly to the next process.assembly linesNo manual handling is required.

②Auxiliary assembly process:When assembling cell phones and washing machines, each step is done on the work plate on the conveyor line. After one station is assembled, the conveyor line sends the work plate to the next station, which can save time.

③Transportation of materials over long distances:When the two workshops are far away from each other, it can be used to convey materials continuously without having to call a forklift frequently.

④Complex sorting and multi-layer conveying:Some factories need to classify different products, or the workshop has two floors, it can realize the material diversion, merging, and even send the material from the first floor to the second floor, which is very flexible to use.

II. Common五layout of a speciesformality

Although they are all chain conveyor, the layout is different and can realize different functions, mainly there are the following five kinds:

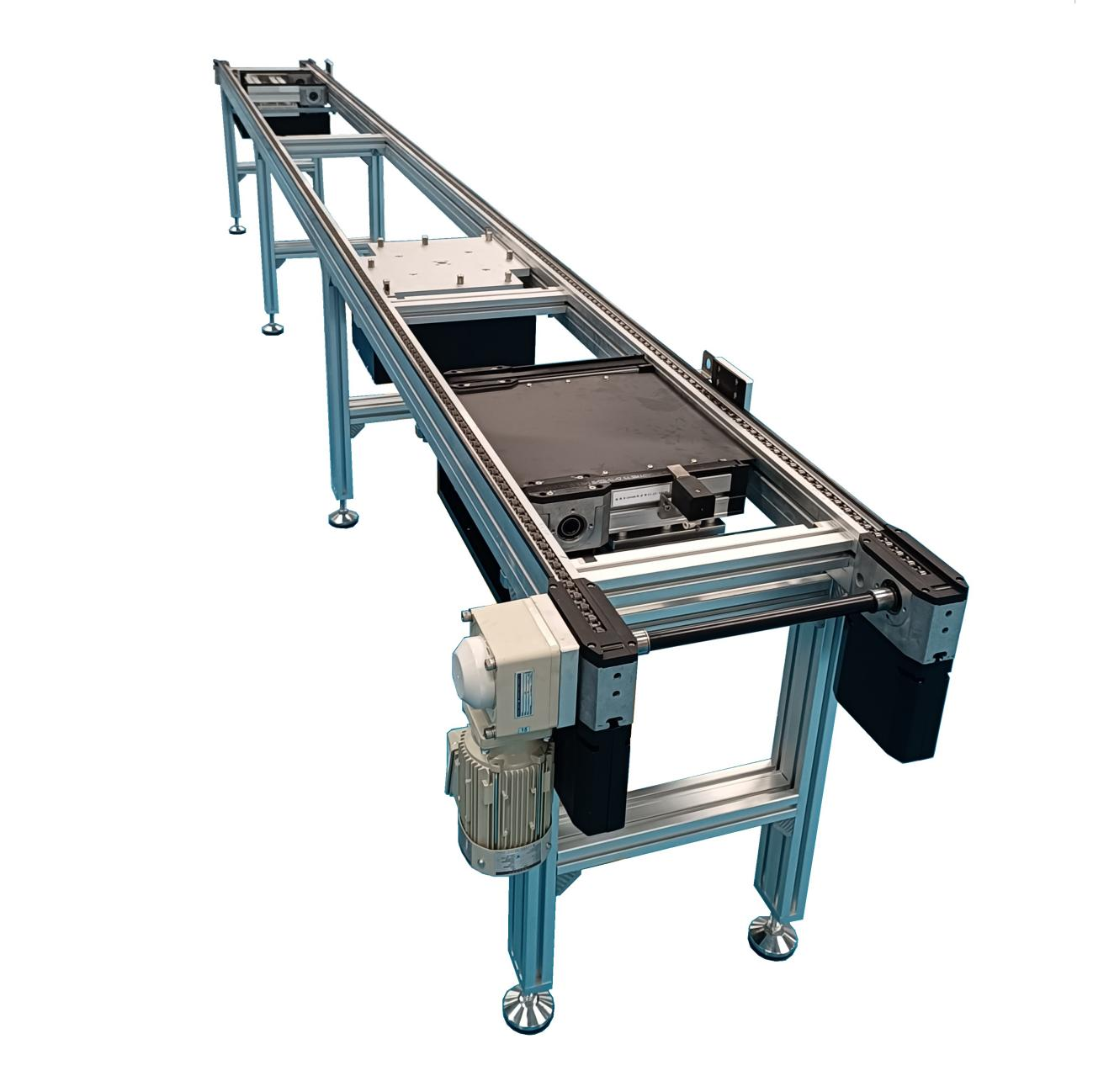

linear. It's the simplest layout, which is a straight conveyor line.

a circular plane.. Like a roundabout, it can form a closed circle.

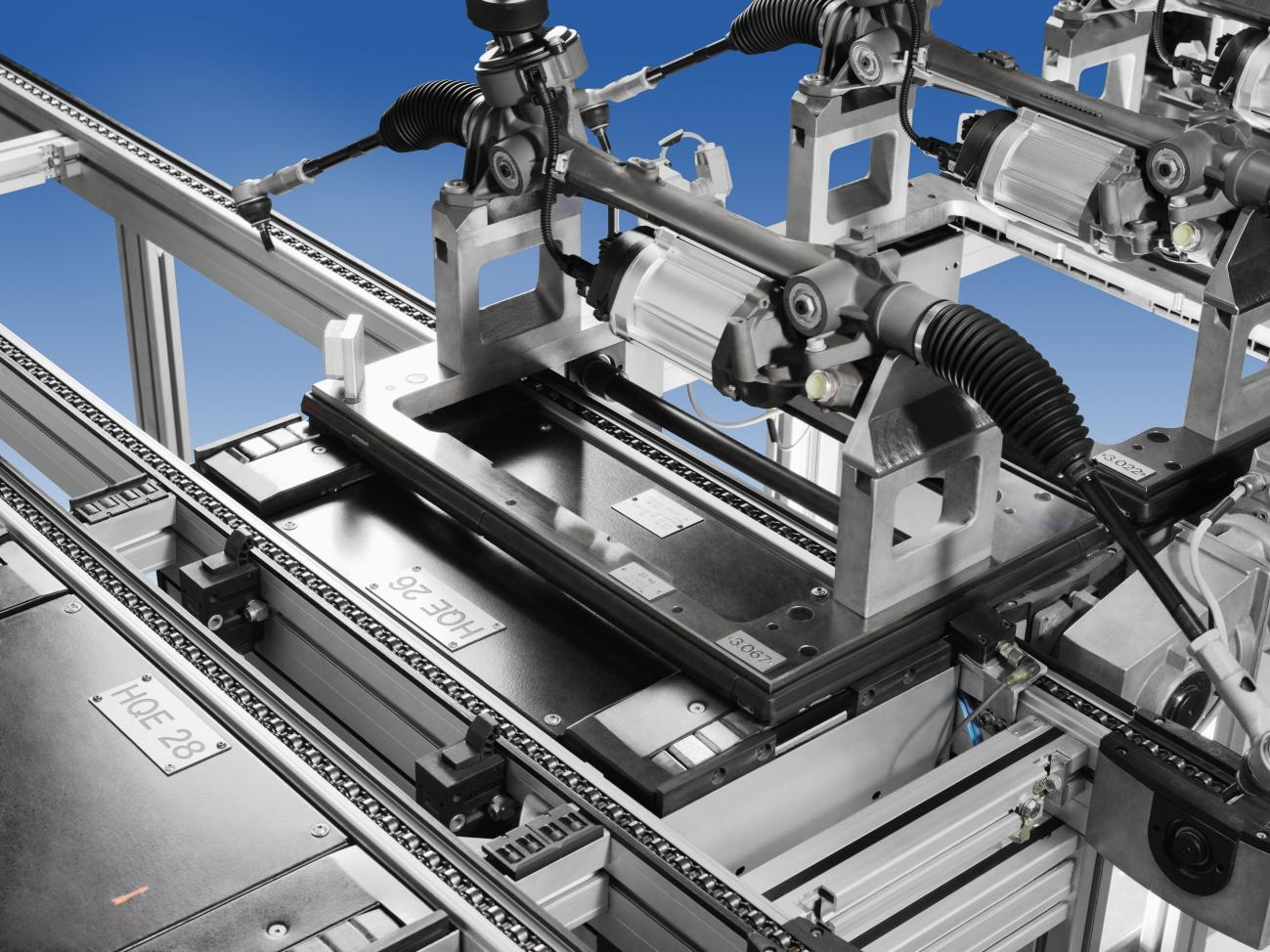

accumulative. It has more stopper than normal conveyor line, which can stop the work plate at the specified position.

Multi-Channel/Branch Type.. There is a fork-like structure that allows material to be diverted from one line to another.

Vertical lifting. Combines an elevator-like function to convey materials up and down.

III. Each layoutseparately or individuallycompetitive edge

The benefits of the different layouts are clear and factories can choose according to their needs:

1,linear

The advantages are simplicity, no hassle in manufacturing and installation, and low cost, suitable for scenarios where only straight conveying is required, such as linear conveying between two workshops.

2,a circular plane

achievablecirculating conveyorThe material can be sent back to the starting point after a circle, especially suitable for the assembly, testing and packaging line of electronics and electrical appliances. For example, cell phone assembly, the work plate can complete all the processes by turning a circle, high efficiency, is now more used in factories of a kind.

3,accumulative

No need to stop the motor to store materials. For example, if a workstation is working slowly, the material in front can stop and wait on the conveying line first, and the material behind will not be blocked, and when this workstation finishes its work and unblocked, the material can continue to be conveyed, which can ensure that the production line is not jammed.

4,Multi-Channel/Branch Type

Highly flexible, it can realize diversion and merging, as well as sorting and discharging materials, which is suitable for complex production systems, such as logistics sorting lines or multifunctional mixed production lines.

5,Vertical lifting

The biggest advantage is space-saving, suitable for plant area is small or need to multi-storey operation, without taking up additional ground area, you can send the material from the first floor to the second floor, so that the plant space utilization is more reasonable.

Speed Chain Conveyor LineThere is no best layout, only the most suitable one!The core role is to help factories save labor and improve efficiency. Whether it is simple linear conveying, or complex ring or multi-layer conveying, the core role is to help factories save labor and improve efficiency. So for the speed chain conveying lineLayout OptionsIt is important to think more before deciding to use the minimum cost for the maximum profit, which is theindustrial automationThe true meaning of the word.