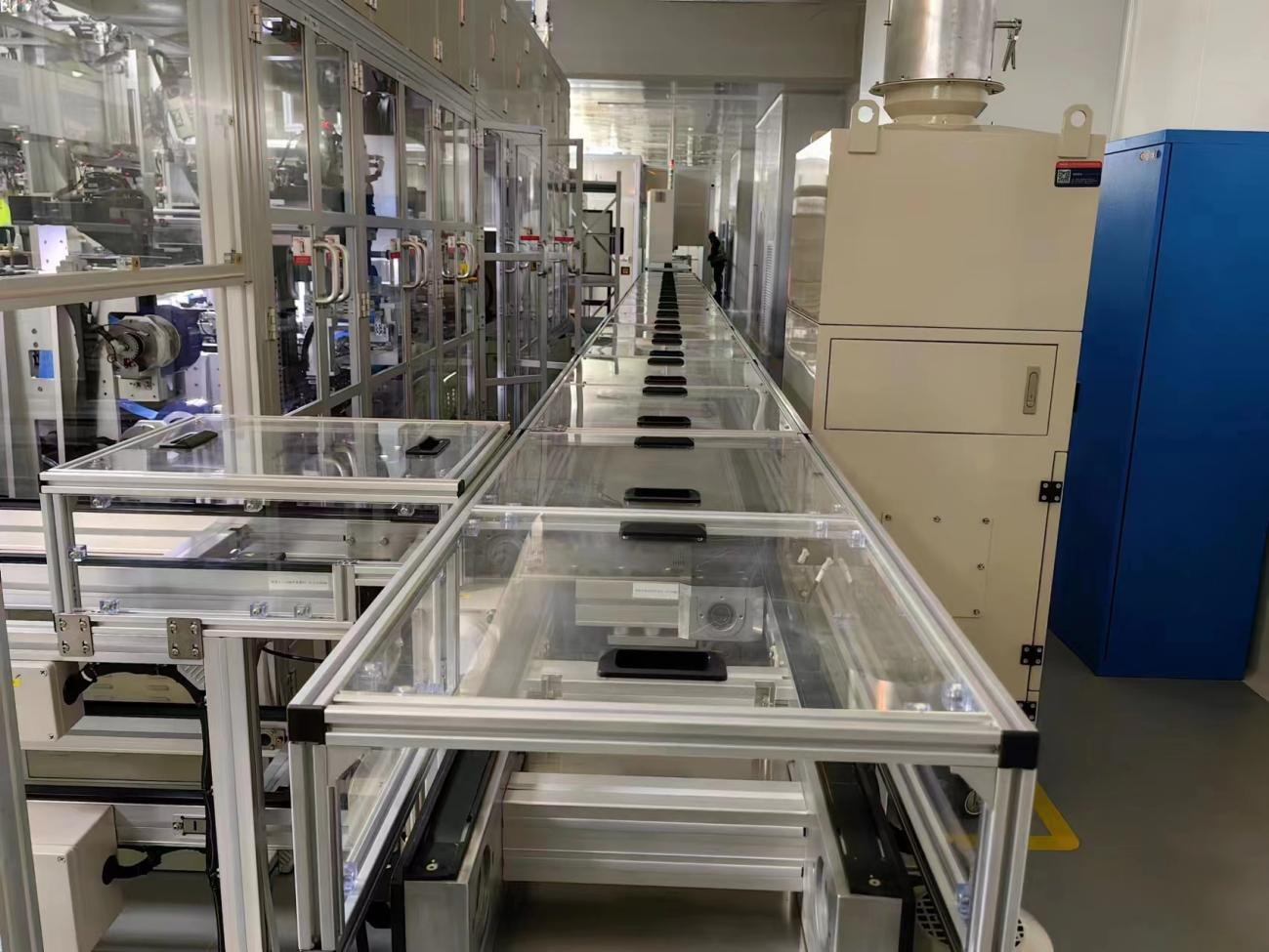

In the context of smart manufacturinglogistics automationbecome the key to reduce costs and increase efficiency of enterprises.Pallet conveying lineAs an important equipment in the logistics system, it has been widely used in the production and logistics link of many industries by virtue of its high efficiency, flexibility and intelligence.

One,Main application industries

1,Logistics and Warehousing

- As the core equipment of the automated warehousing system, it realizes the unmanned operation of the whole process of goods from warehousing, temporary storage to warehousing;

- Through the multi-layer line body and elevator structure, connecting the three-dimensional warehouse and production line, to improve the efficiency of access to the warehouse;

- With RFID, WMS system, accurate identification of cargo information, to meet the high-frequency distribution needs of e-commerce, shoes and apparel and other industries;

- Adopting three-dimensional design, maximizing the use of storage space, adapting to the high land cost of logistics centers in first-tier cities.

2,Automobile manufacturing industry

- It is characterized by high precision and high stability to guarantee the production beat;

- electrical machineryIn the assembly process, the U-shaped layout of the 40-meter-long conveyor line with jacking and positioning and rotating devices realizes fully automated assembly with a very low error rate;

- heavy load (on a truck)doubled speed chainThe pallet conveying line can carry thousands of pounds of battery modules to complete the integrated process of assembly, testing and packaging;

- High-temperature-resistant models can operate stably at 150°C to meet the demanding process requirements of parts drying and cooling.

3,Food and Pharmaceutical Industry

- Adapted to the industry's high cleanliness standards, made of plastic or stainless steel, corrosion-resistant and easy to clean;

- It can operate stably in low-temperature environment and guarantee the whole constant-temperature transportation of temperature-sensitive products such as fresh food and vaccines;

- Seamless docking of filling and sealing machines, reducing manual contact and avoiding cross-contamination.

4,New Energy and Chemical Industry

- Highly loadable and secure, adapted to heavy-duty and high-risk scenarios;

- In lithium battery production, it carries super heavy materials with explosion-proof design to ensure safe production in high-risk environments;

- Together with the pallet packing system, it realizes the whole unmanned process from storage to loading of flammable chemicals, and avoids the hidden danger of forklift safety;

- Slat and roller models are designed for heavy-duty raw materials, reducing transportation losses and improving production line continuity.

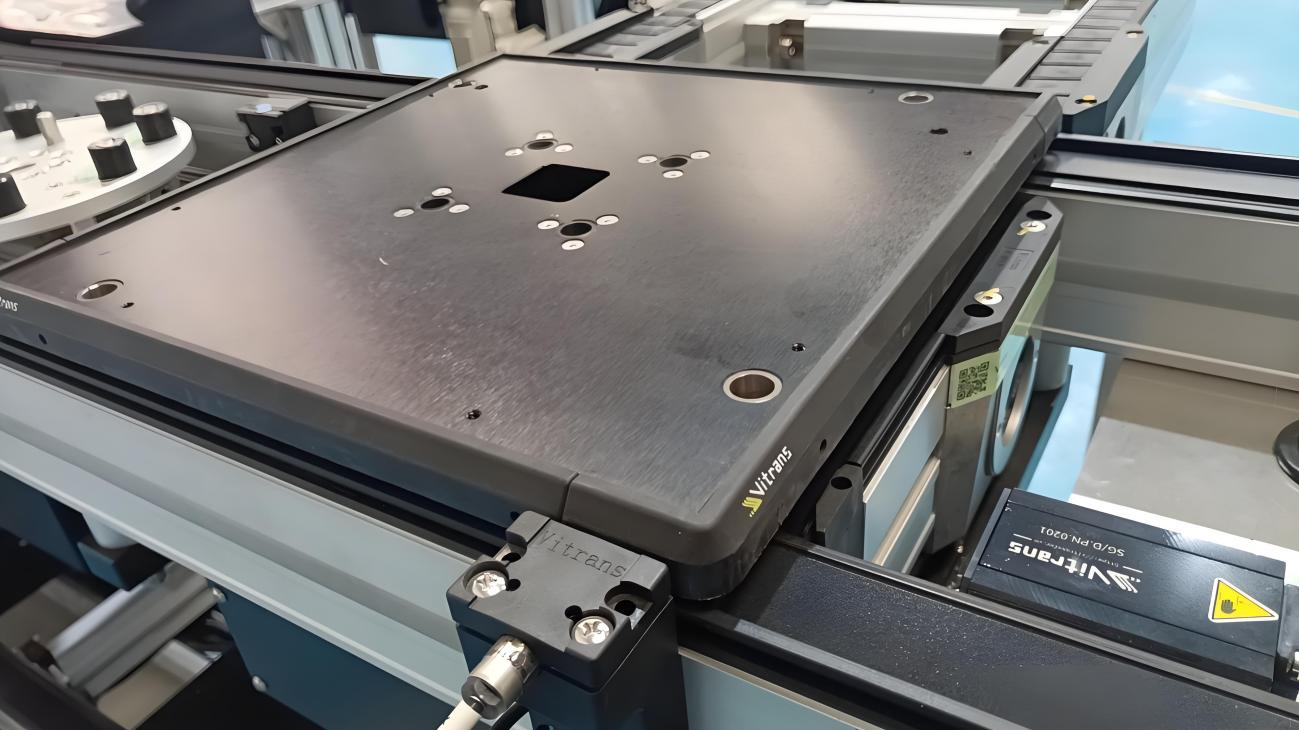

5,3C Electronics Industry

- Highly flexible and adaptableprecision manufacturingand multi-species production needs;

- Belt-type model with anti-static design ensures damage-free transportation of precision electronic components such as PCBA boards;

- The modular design allows for quick adjustment of the conveying path to meet the needs of small-lot and multi-batch production of cell phones and chips;

- Equipped with sensors to monitor the pallet position and equipment status in real time to reduce the failure rate.

II. SelectionPallet conveying linecore strengths

- Efficiency gains: 24-hour operation and increased cargo throughput compared to traditional methods.

- Cost optimization: Reduced labor dependency and maintenance costs of 1/3 of traditional equipment

- Intelligent collaboration: can work with AGVs and robotic arms to help enterprises create more efficient automated production.

From logistics and warehousing to automobile manufacturing, from food and medicine to new energy.Pallet conveying lineIt has become a practical choice for various industries to improve logistics efficiency and ensure production safety. Whether the enterprise pursues efficiency improvement or strictly abides by safety standards, it can be achieved through theCustomized SolutionsMeet the demand and help your organization grab an edge in the automation wave!