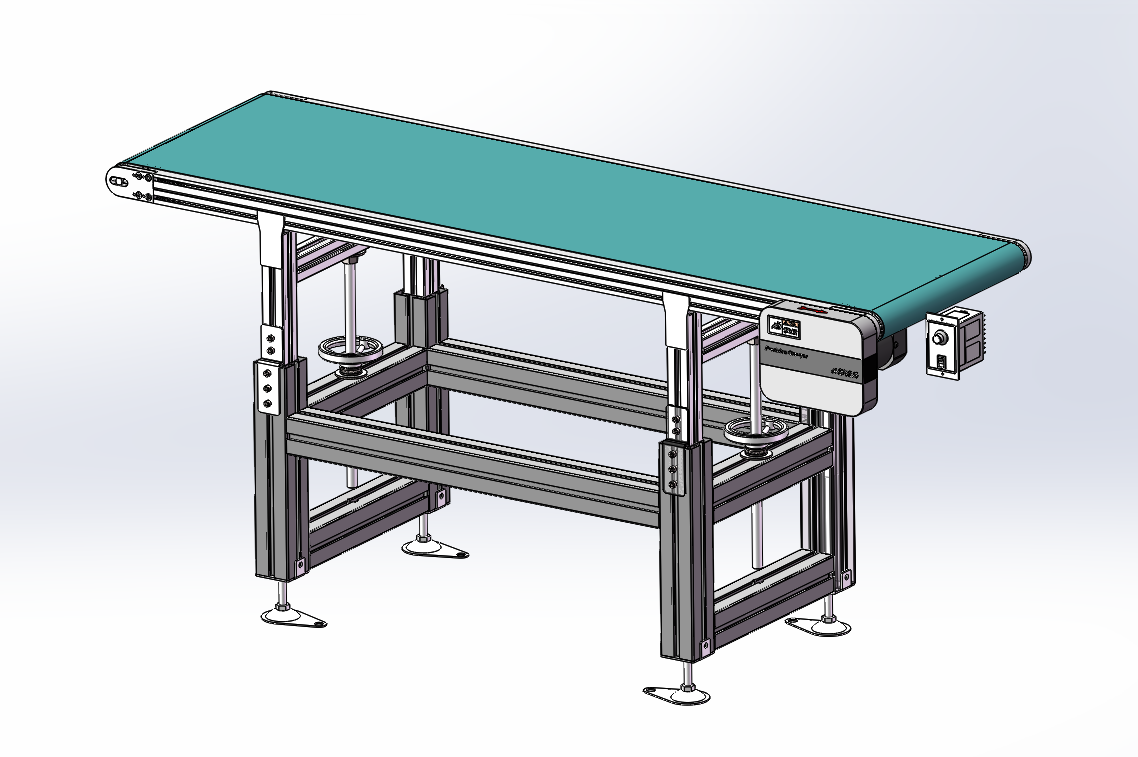

belt conveyorIt is a very key equipment in the production line. Look simple, but can directly affect the efficiency of the entire assembly line. Many factories spend a lot of money to buy high-end processing equipment, belt conveyor on the idea of “saving money”, and finally led to the efficiency of not on, loss can not be reduced. In fact, it is only 5% to 10% of the total budget of the assembly line, but can affect the efficiency of the operation of 80%. The following combination of common contactbelt conveyormodels, sharing 3 keys to selection to help you avoid invisible problems.

01 beltChoose the right material, the material is safe

Belt material is directly related to material safety and equipment life. If you don't choose the right one, the belt may have to be replaced frequently, and in serious cases, it will contaminate the material and cause losses.

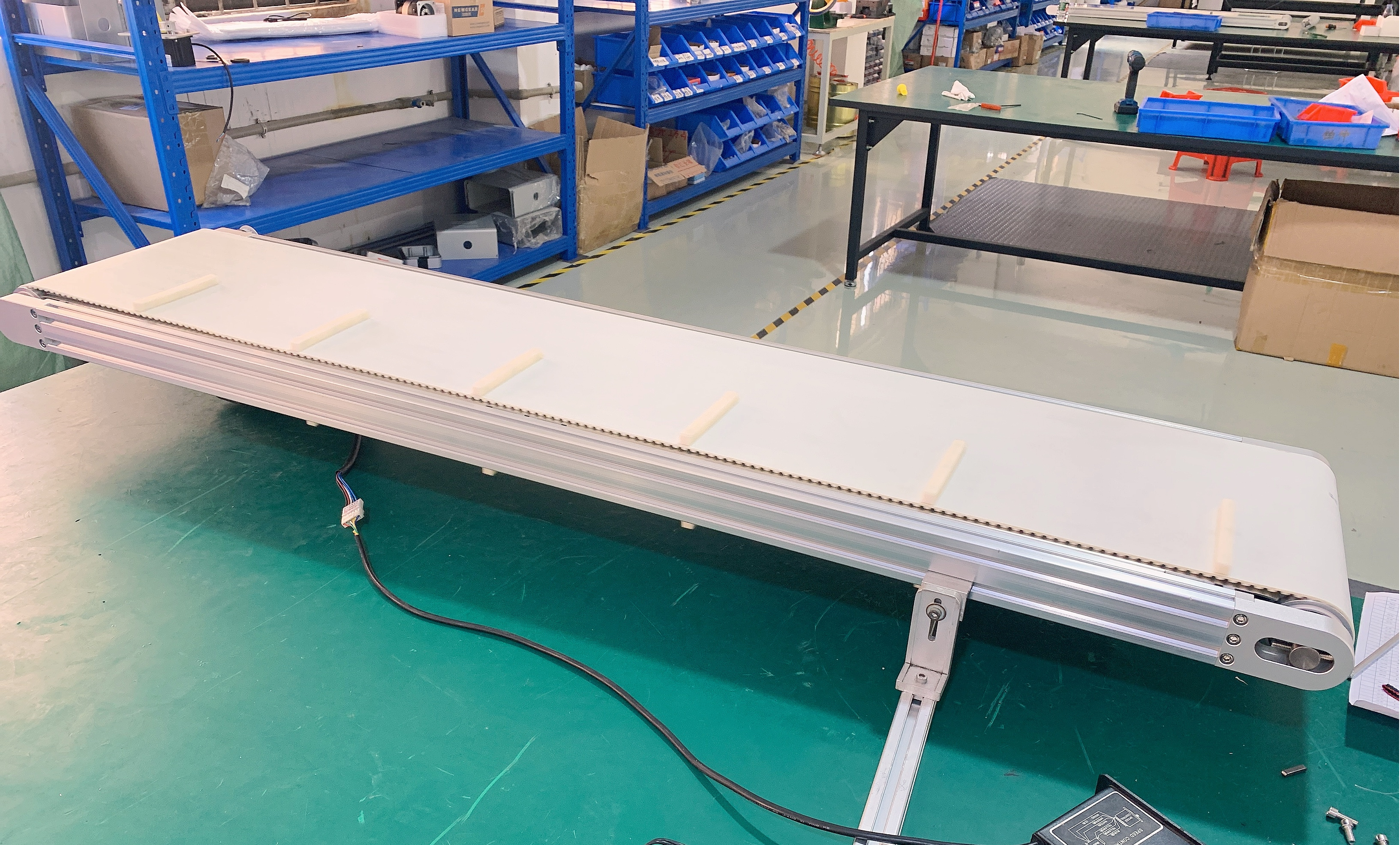

- Food industry must choose food-grade PU (polyurethane) or silicone material, but also through the FDA certification, do not use rubber material, easy to have odor contamination of food. If the conveyor is a high temperature baked goods, to choose the Teflon coated belt can withstand high temperatures of more than 200 ℃. Wide belt baffle customized type can withstand 0 to 20 kg, suitable for food sorting, customized baffle can also distinguish between different categories of food.

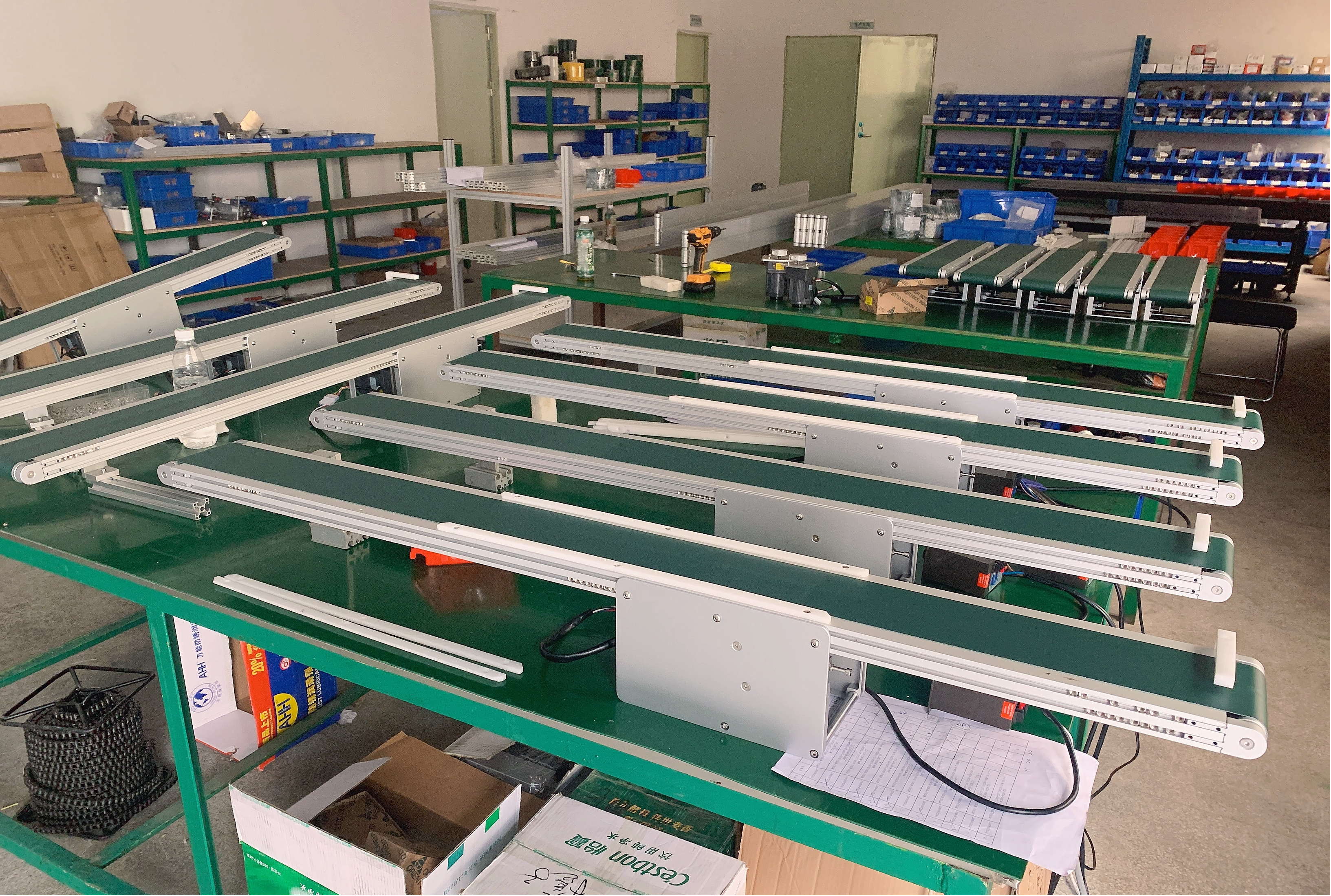

Precision components in the electronics industry are afraid of static electricity, you have to use anti-static belts, the surface resistance should be between 10 ⁶ to 10 ⁹ Ω, otherwise the static electricity may break through the chip.Narrow belt single row typeSuitable for watch and jewelry processing, and the dual-row type is suitable for electronic plug-in processes, both of which can meet the demand for precision positioning.

- When conveying metal parts, ores and these heavy materials in heavy industry, choose a strong belt with rubber plus wire rope core, which can reach a tensile strength of more than 500N/mm. Wide belt standard general-purpose type can withstand 0 to 200 kg weight, and can be efficiently conveyed in narrow environments, suitable for heavy-duty scenarios.

02Choose the right drive to run efficiently

The drive motors have to be right for the capacity needs, or else they either don't have enough power to pull, or they have too much power to waste.

- Small and medium capacity production line, less than 50 tons per hour conveying capacity, choose frequency conversion motor can be. The speed can be adjusted between 0.5 and 5 meters per minute, such as cosmetic packaging, small medical supplies can be used.Wide Belt ConveyorCapable of handling weights from 0 to 100 kilograms, it is compact and the motor is housed internally for easy integration into complex production lines.

- For scenes requiring high positioning accuracy, such as lithium battery pole piece conveying, precision parts assembly, choose servo motors, positioning accuracy can reach ± 0.1 mm.Narrow belt single row type和Double column typeAll support precision positioning, whether it is tiny parts or palletized products that can be accurately conveyed.

- For large capacity production lines, conveying more than 100 tons per hour, such as building material plants and ore conveying, choose a geared motor. It can provide high torque and will not slip even if the belt is fully loaded. The wide belt standard general-purpose has a high load capacity and can meet the demand of heavy-duty continuous conveying.

03Auxiliary devices do a good job, the assembly line is not jammed

Many people do not pay attention to the auxiliary devices, in fact, these small details can avoid assembly line jamming and reduce failures.

- The belt will slacken after a long time, installing an automatic tensioner can adjust the tension in real time and reduce the slipping problem. A furniture factory's board conveyor line installed, the number of failures per month from 8 times down to 1 time.

- When conveying cylindrical and irregularly shaped materials, lateral guides or baffles should be added. Wide belt baffle customized type of baffle can be customized, not only to prevent the material from running out of order, but also to make the food and daily chemical products in order, which is convenient for the operation of the subsequent process.

- The surface of the belt is easily stained with dust and oil, which will contaminate the material. Food production lines should be cleaned with food grade brushes and high pressure water, electronic production lines with vacuum suction devices, and heavy industrial production lines should be equipped with scrapers to remove impurities.

04selectionprerequisites

In addition to these three points, consider the installation space and budget. If the space is narrow, choose a model with a single slot profile, such as thegenerously sized beltStandard general-purpose type; if you have enough space, choose double column type such as narrow belt double column type, which can improve the conveying efficiency. Dual-row type structure is more complex, the price is higher than single-row type, to meet the production requirements under the premise of balancing the budget.

选belt conveyorBefore that, think about the material, such as weight, temperature, fear of static electricity; capacity requirements, that is, how much to convey per hour; workstation layout, such as whether to turn, lift. Then compare the load capacity, structure and applicable scenarios of the model, you will be able to choose the right equipment, so that the smooth operation of the assembly line, higher efficiency.