When the factory production line is in production, is it often encountered that the conveyor line is jammed, the load is not enough, and the chain is loose? When these problems occur, the production rhythm is directly disrupted. Wei Chuang independent research and development of independent productiondoubled speed chainconveying lineIt is a practical choice for large-load production scenarios, as it can bear a maximum load of 4000 kg and can be transported stably without running away.

One,What kind of conveyor line is this?

Simply put, this is an automated conveyor that focuses on “large load + high stability”:

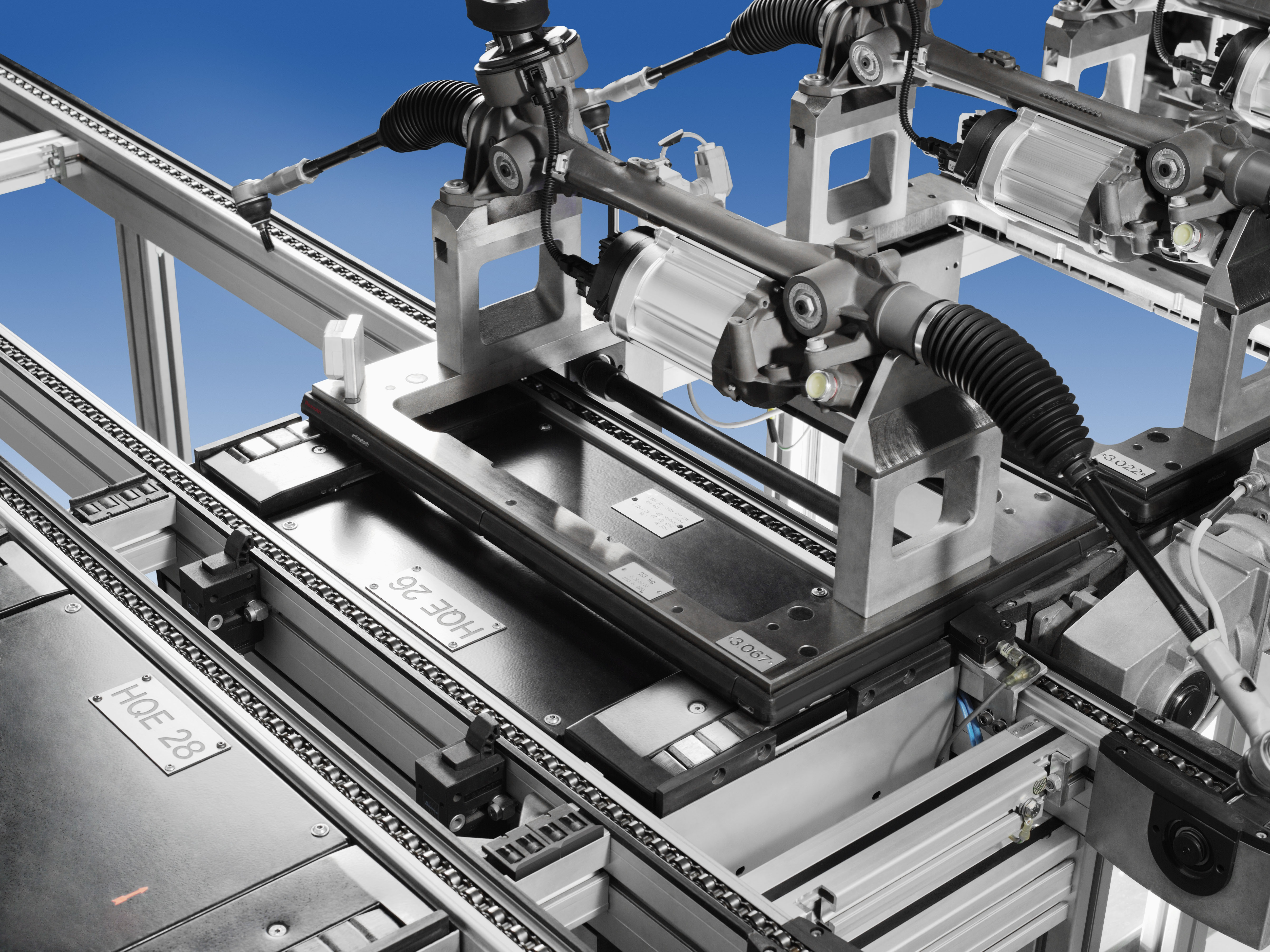

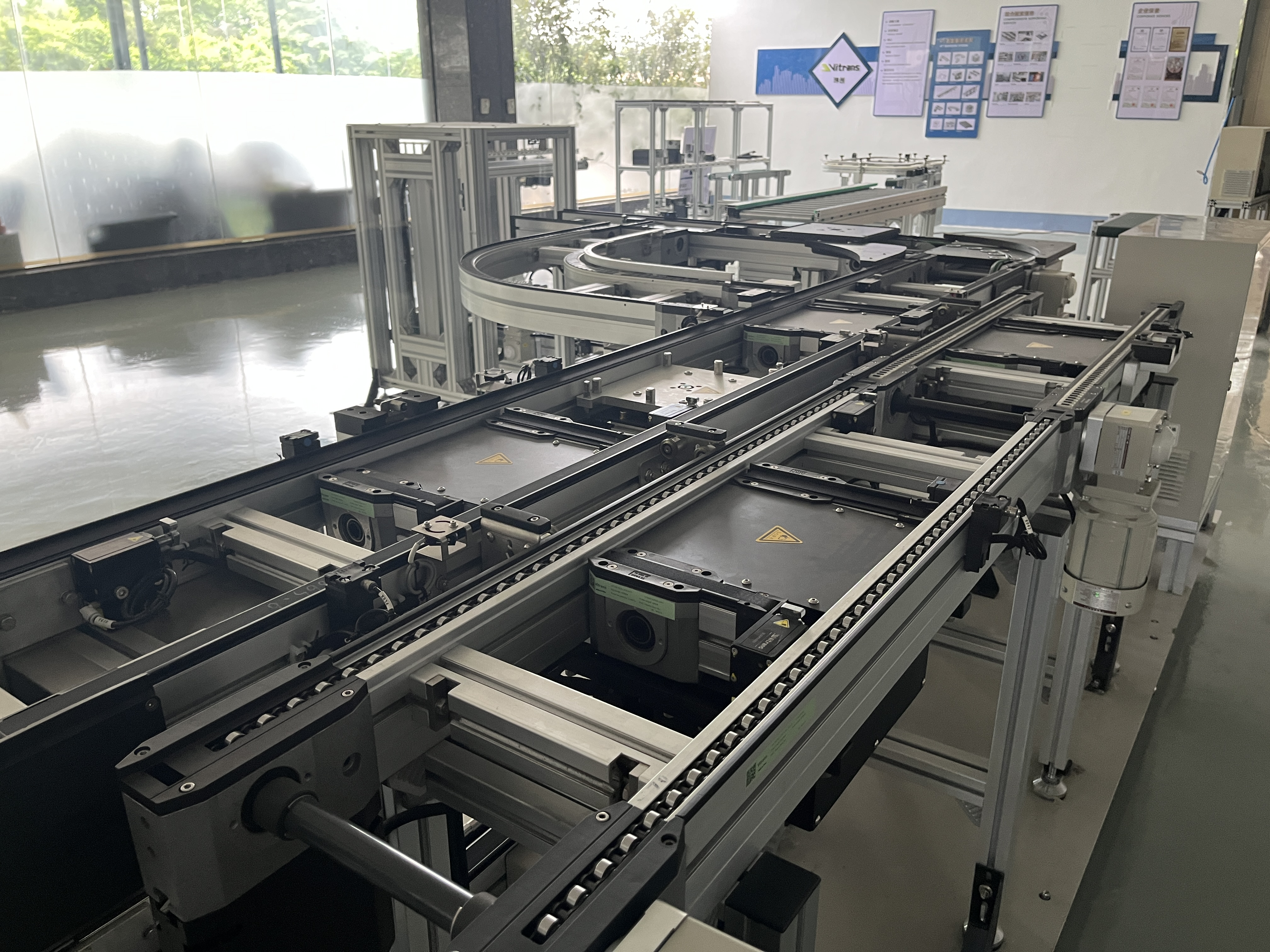

It is paired with pallets and reinforced profile frame, a dozen pallets with a total weight of more than 2,000 kilograms, the chain runs without the slightest jams; even in high-speed operating conditions, the profile frame will not run off, conveying the entire smooth and smooth, not only to carry the pressure of heavy loads, but also to stabilize the rhythm of conveying.

Two,Speed Chain Conveyor Linecore strengths

1,Stabilized loads

With a maximum load capacity of 4,000 kg, the heavy workpieces can be transported centrally without jamming; the reinforced profile frame structurally avoids the problem of deflection, and remains stable at high speeds, which is suitable for high-rhythm production needs.

2,Durability Pulled Full

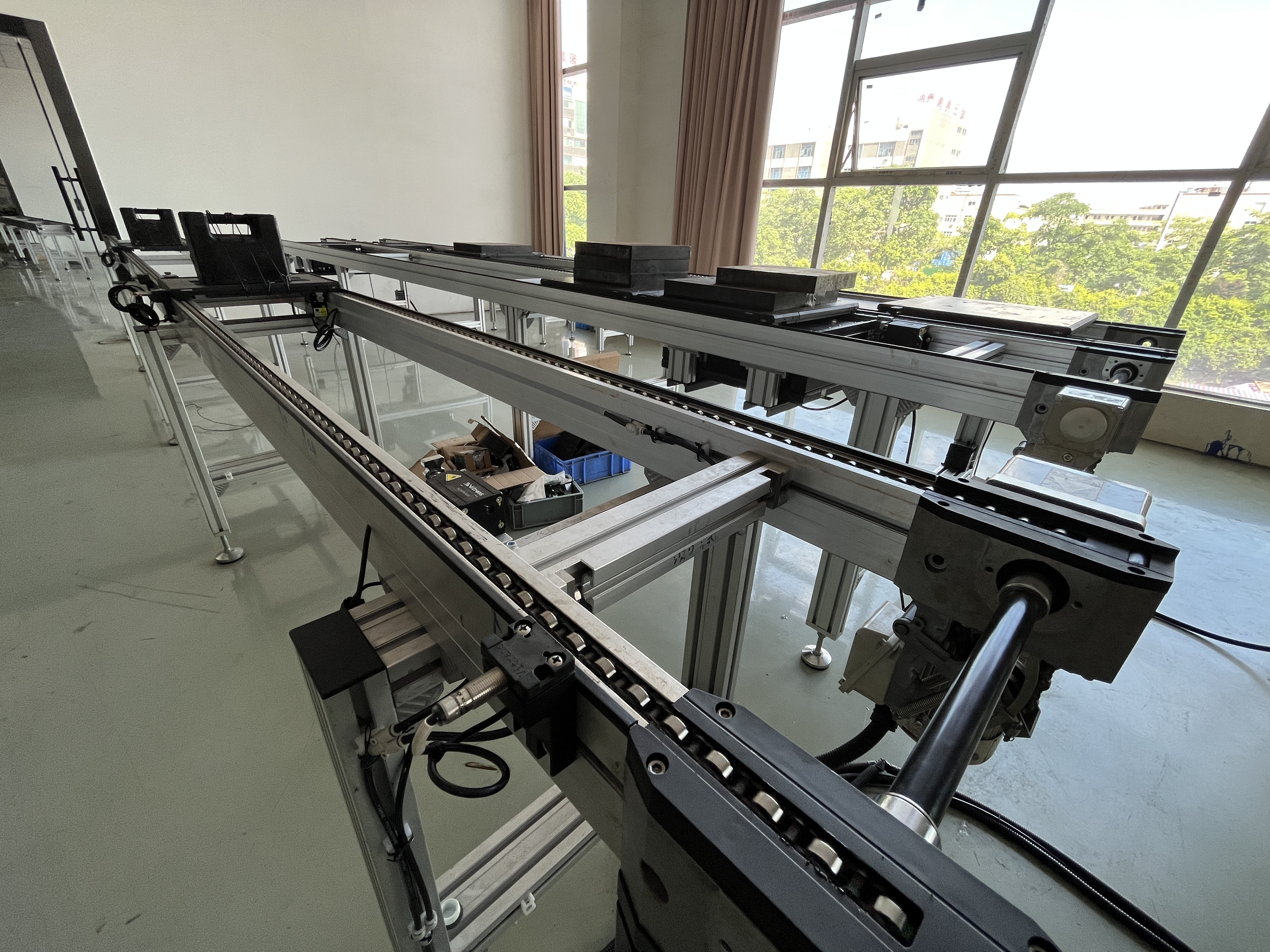

Adopting steel and copper roller to replace the traditional sliding friction design, wear-resistant and anti-build, not easy to be damaged even after 3 or 5 years of use; upgraded chain material, also with an automatic tensioning device, which can adjust the chain back to the normal state at any time, without frequent manual adjustment.

3,Low maintenance costs

The chain of the traditional multiplier chain is often changed once a year, and the chain of this conveyor line runs continuously for 10,000 hours just for starters, which not only reduces the downtime for maintenance, but also saves the cost of frequent replacement of parts.

Two,Comparing traditional multiplier chains: what's so great about it?

legacySingle speed multiplier chainThe common problems are very prominent: the chain is easy to collapse, conveyor jamming downtime, frequent delays in production;

this oneSpeed Chain Conveyor LineJust made up for those shortcomings:

- The chain is not loose: the automatic tensioning device solves the slack problem;

- No jamming: steel and copper rollers + reinforced frame for more stable transportation;

- MORE DURABLE: The upgraded material has a much longer service life than the traditional model, and the productivity is more guaranteed.

Three,What usage scenarios is it suitable for?

The large load + high stability attributes of this conveyor line are just right for these scenarios:

- Auto PartsAssembly:Carries heavy parts such as lights and dashboards to match the pace of continuous operation;

- New energy lithium battery production line:Stable conveyance in a clean environment, suitable for the assembly process of cores and modules;

- Manufacture of complete home appliances:Multi-process flow of large workpieces such as air conditioners and refrigerators, compatible with loads of different sizes;

- Heavy duty hardware machining:Inspection and packaging conveyance of large-weight hardware to avoid jamming and running.

For manufacturing companies with large loads and stable conveying needs, thisSpeed Chain Conveyor LineIt is one of the best choices for improving production efficiency, as it solves the “minor problems” of traditional conveyor lines and reduces long-term maintenance costs.