Now that we're automating production in the factories.Pallet conveying systemsIt is an indispensable mechanical equipment in material flow. And the elevator as the key equipment to connect the high and low levels of the conveyor line, can solve the problem of pallet up and down the conveyor, but also to replace the traditional manual handling of the inefficient mode. So no matter in lithium, electronic appliances, or general manufacturing industry, lifting machine can meet different production needs, so that the pallet transfer to form a cycle of transportation, maximize production efficiency. Currently adapted toPallet conveying lineThere are three types of mainstream hoist, each with its own advantages, adapted to different production scenarios, the following is a brief introduction for you:

One,Synchronous belt elevator

It is driven by a servo motor, which can accurately stay in different positions. The single pallet can carry 30 kilograms of weight, and the beat is controlled within 8 seconds. It is most commonly used in lithium battery cell assembly line. Because chain drive will produce metal powder, affecting the quality of the core, synchronous belt will not have this problem. Some people worry that the belt will break, affecting production efficiency. In fact, like conveying the core of this relatively light products, as long as the load is calculated, the belt breakage is rare. And we also installed a fall prevention device, do not have to worry about the problem of crashing the machine. This hoist is also cost-effective, can meet the use of multi-layer conveying line in theLithium industryUsed very much.

Two,Rodless Cylinder Lifter

It relies on rodless cylinders to lift and lower, also capable of carrying 30 kilograms, with a lifting speed of up to 300 millimeters per second. It can only be used to complete the conveyance between two layers of wire body, generally mounted on thedoubled speed chainIt is responsible for the vertical transportation of the pallet between the high and low levels. And it up and down drive by rodless cylinder IO control, without servo drive, it is very convenient to use. At the same time, the simple structure of rodless cylinder is not easy to wear and tear, low maintenance cost in the later stage, which is very suitable for enterprises that have clear requirements on operation convenience and maintenance cost.

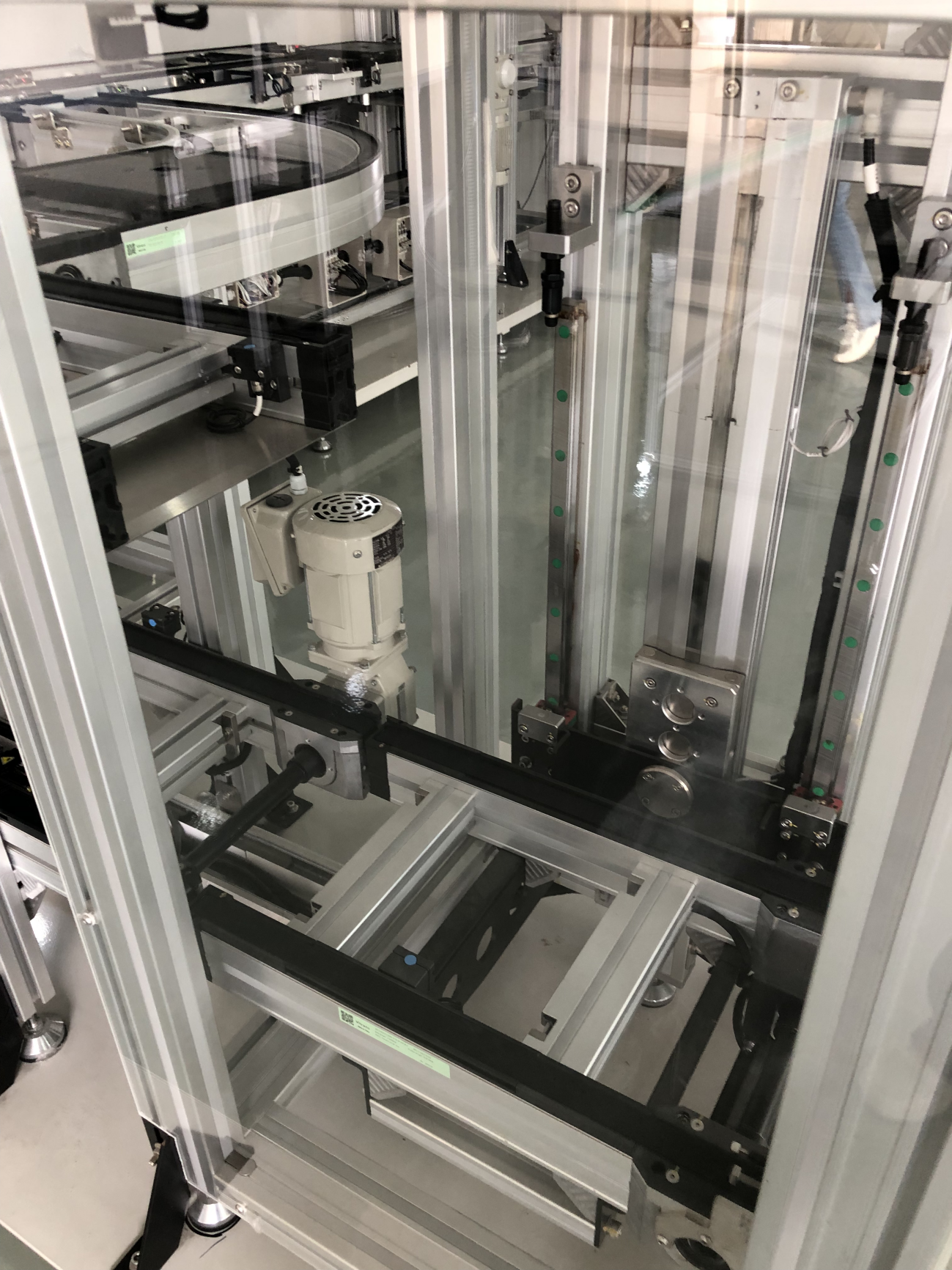

Three,Screw jacks

It is also servo motor driven, with faster lifting and lowering speed, which can reach 500 millimeters per second. It can drive the pallet in the multi-layer conveyor line between the transit transfer, but also allows the pallet stacking storage, to meet the requirements of different production scenarios on the production rhythm. This elevator looks ordinary, but the structure is compact and small, the installation and subsequent maintenance is convenient and hassle-free, and the service life is also long. And pallet conveyor line with the use of the real time-saving, labor-saving, labor-saving.

Many companies will worry that the hoist does not fit their factory application, such as the size of the site, the weight of the goods is not the same, it can not be adapted. We(reddish jade)As a source manufacturer, we are able to specialize in designing suitable solutions according to the actual factory site, the weight to be carried, and the usage environment, to ensure that the elevator and pallet conveyor line match the factory production scenario.

If your factory has the demand for pallet conveying, and need to realize the layout of the upper and lower cycle conveying, you may want to look at these three lifting machine, so that automation equipment for factory production empowerment, improve efficiency at the same time, so that the capacity of more stable.