In the intelligent transformation of manufacturing industry, automated production line has become the key to improve efficiency and reduce costs. It can not only break the limitations of manual operation, realize continuous, standardized production, but also through accurate control to ensure product quality, to help enterprises in the fierce competition in the market further. Among the many automated conveying equipments, thedoubled speed chainConveyor line (Vitrans AC2/AC2/H)Stacked Roller Chain Conveyor LineThe company has become the preferred choice for automotive parts, new energy, electronics and electrical appliances industries, and an indispensable link in automated production due to its unique advantages.

Speed Chain Conveyor LineThe core strengths are centered on the following four points:

One,Modular design for flexible adaptation to multiple needs

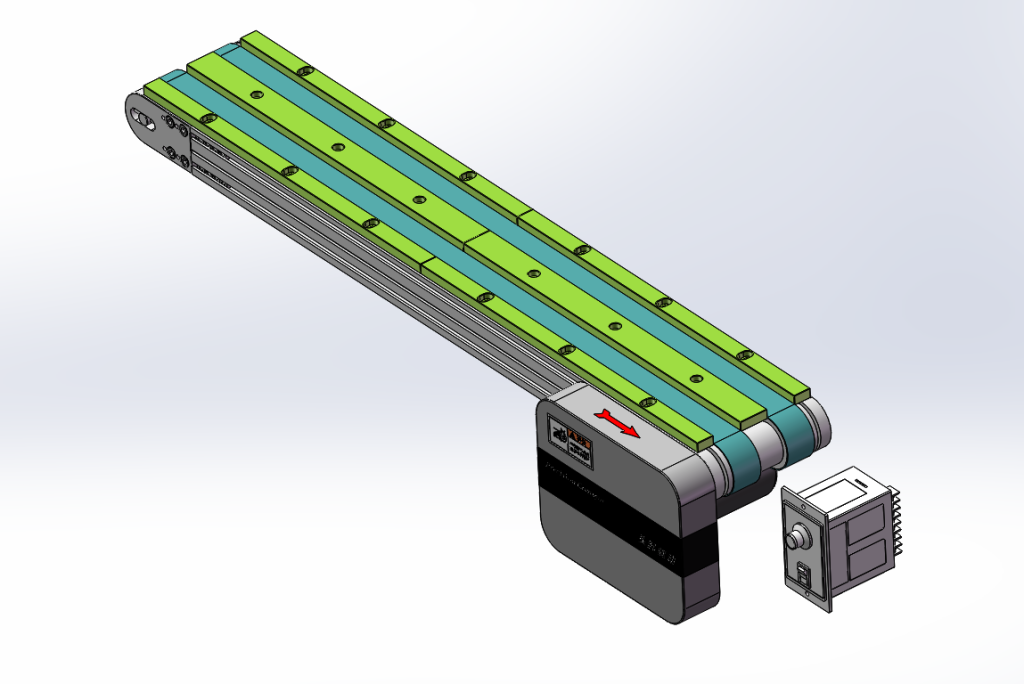

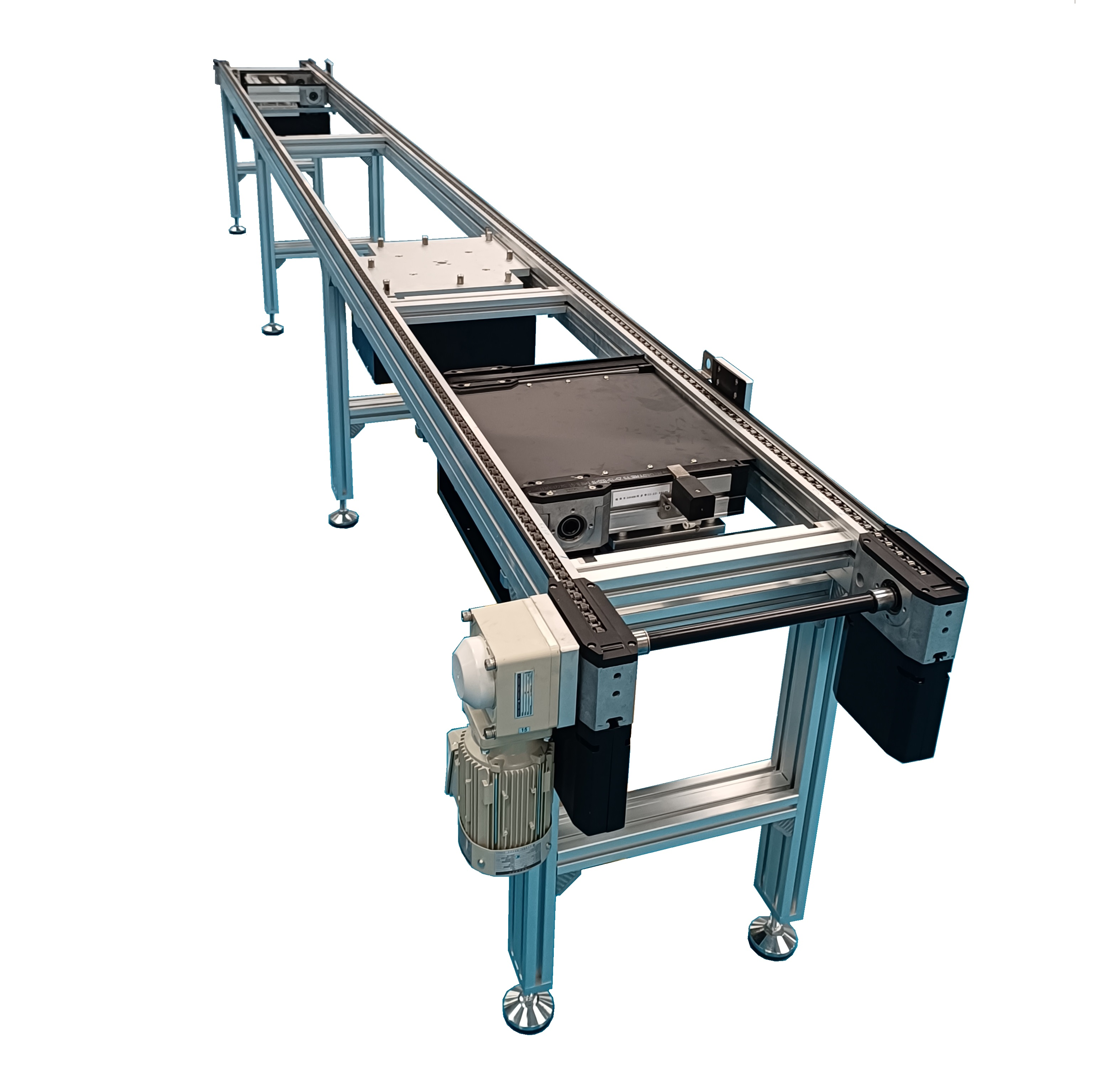

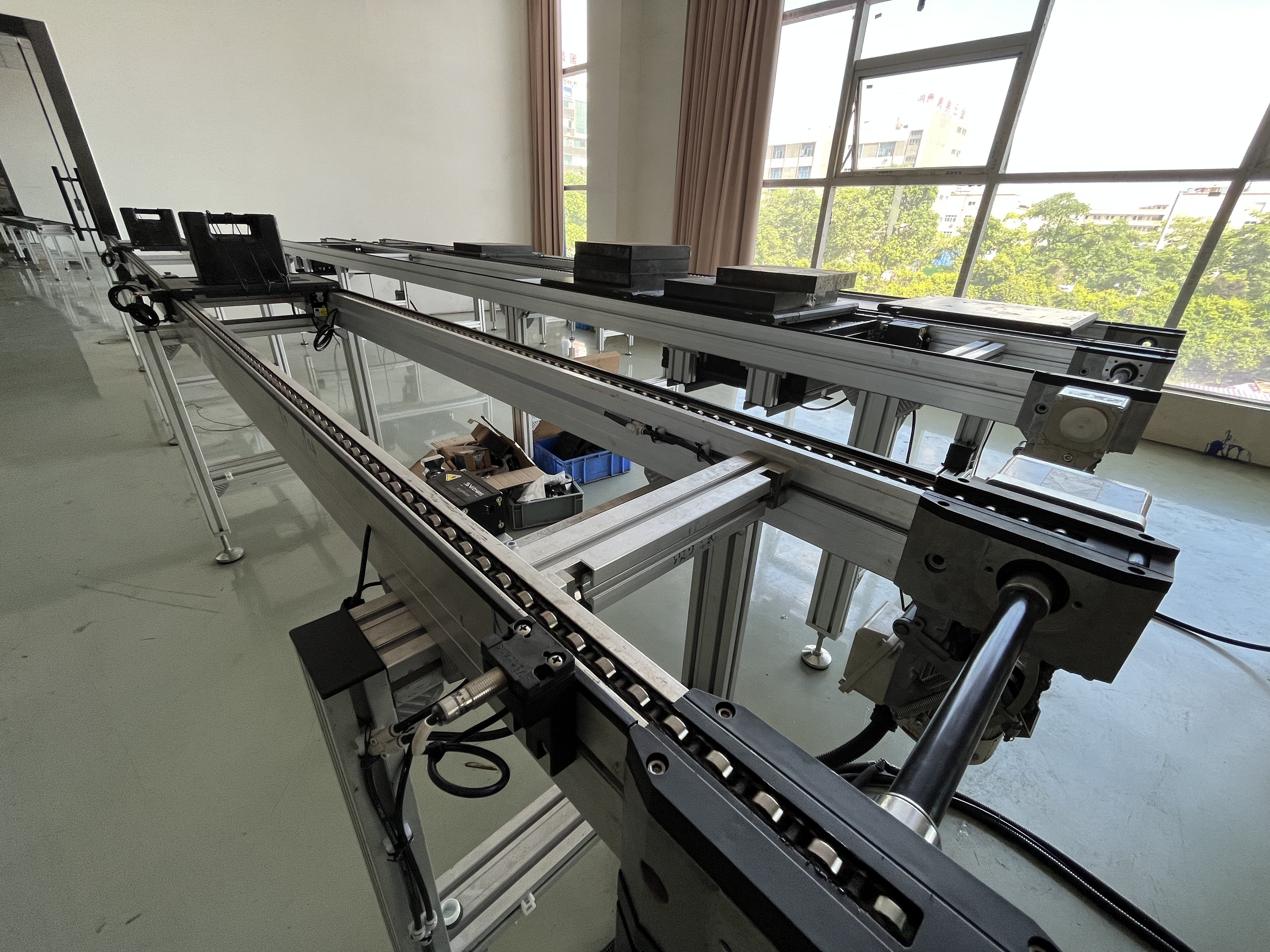

Speed Chain Conveyor LineAdopting standardized modular structure, the line body, driving unit, positioning mechanism and other components can be split and combined separately. Enterprises can flexibly add or subtract conveyor sections or replace functional modules according to the size of production sites and changes in work processes, without the need to modify the system as a whole. Whether it is to add new workstations, adjust the conveying direction, or upgrade the load capacity, it can be realized quickly, which greatly improves the maintainability and expandability of the production line, and adapts to different stages of production needs.

Two,Stable operation to ensure efficient and continuous production

depend onStacked roller chainsWith the transmission characteristics, the speed chain conveyor line operates smoothly without jitter and has high precision of pallet conveying. Its independent three-phase gear motor drive can provide stable power, and the rated speed can be selected from 6-18m/min, and the speed can be flexibly adjusted by frequency converter. At the same time, the line is equipped with perfect stopping and positioning components, which can accurately control the starting and stopping of the pallet and its position, avoiding collision of workpieces or deviation of conveying, ensuring continuous and efficient production process, and reducing downtime loss.

Three,Strong load-bearing capacity, suitable for heavy-duty complex scenarios

Speed Chain Conveyor LineDesigned for heavy-duty scenarios, theAC2 chain conveyor linewith a maximum load of 700 kg.AC2/H Speed Chain Conveyor LineIt can reach up to 2200kg, and the load per unit length can reach up to 2kg/cm (steel wear bar configuration). With WE2 series special pallets, it can stably carry all kinds of heavy workpieces and fixtures, and even in the case of multi-pallet stacking conveying, it can still maintain stable operation, which fully meets the conveying needs of heavy-duty products such as automotive parts and large-scale electronic equipment.

Four,Long service life and reduced long-term cost of use

The line body is made of high rigidity material and wear-resistant design, and the conveying medium is made of nylon or steel.Stacked roller chainsThe conveyor section is equipped with PE wear pads for low wear and tear. Meanwhile, the service life can be further extended by simple maintenance such as regular cleaning and closing the conveying section when idle. Its modularized structure also makes the replacement of accessories more convenient, reduces maintenance time and cost, and has outstanding cost performance for long-term use.

V. Main application industries:

In terms of application scenarios, theSpeed Chain Conveyor LineThe adaptability is also very strong.

- Automotive:Can be used for multi-station flow of engine parts, body structure parts

- New Energy Sector:Capable of carrying battery modules to complete assembly, testing and other processes.

- Electrical and electronic industry:Continuous conveying of large equipment housings and motor components can be realized.

In addition, the multiplier chain conveyor line can also build complex layouts such as horizontal circulation and vertical lifting by combining with turning units, elevators and jacking and positioning mechanisms to meet the individual needs of different production lines.

The proliferation of automated production lines is reshaping the production model of the manufacturing industry, and theSpeed Chain Conveyor LineWith the core advantages of modularity, stable operation, high load-bearing and long life, it has become an important booster for enterprises to improve production efficiency and optimize processes. Whether it is a new automated production line, or upgrading and remodeling the traditional production line, theSpeed Chain Conveyor LineWith its flexible adaptability and stability and reliability, it can create greater value for enterprises. If you have the need for customized conveyor lines, Wei Chuang can provide you with the whole process from the solution to the after-sales service.