In the automated production plant.Pallet conveying lineLayout is not as simple as just swinging. Choose the right layout, can make the workpiece flow more smoothly, more efficient use of space, the production of beat speed; layout is not appropriate, on the contrary, it will cause process congestion, waste frequently. Today to dismantlePallet conveying lineThe two core layouts - horizontal circulation layout and vertical circulation layout - help you find the optimal solution for your own workshop.

One,Horizontal Loop Layout

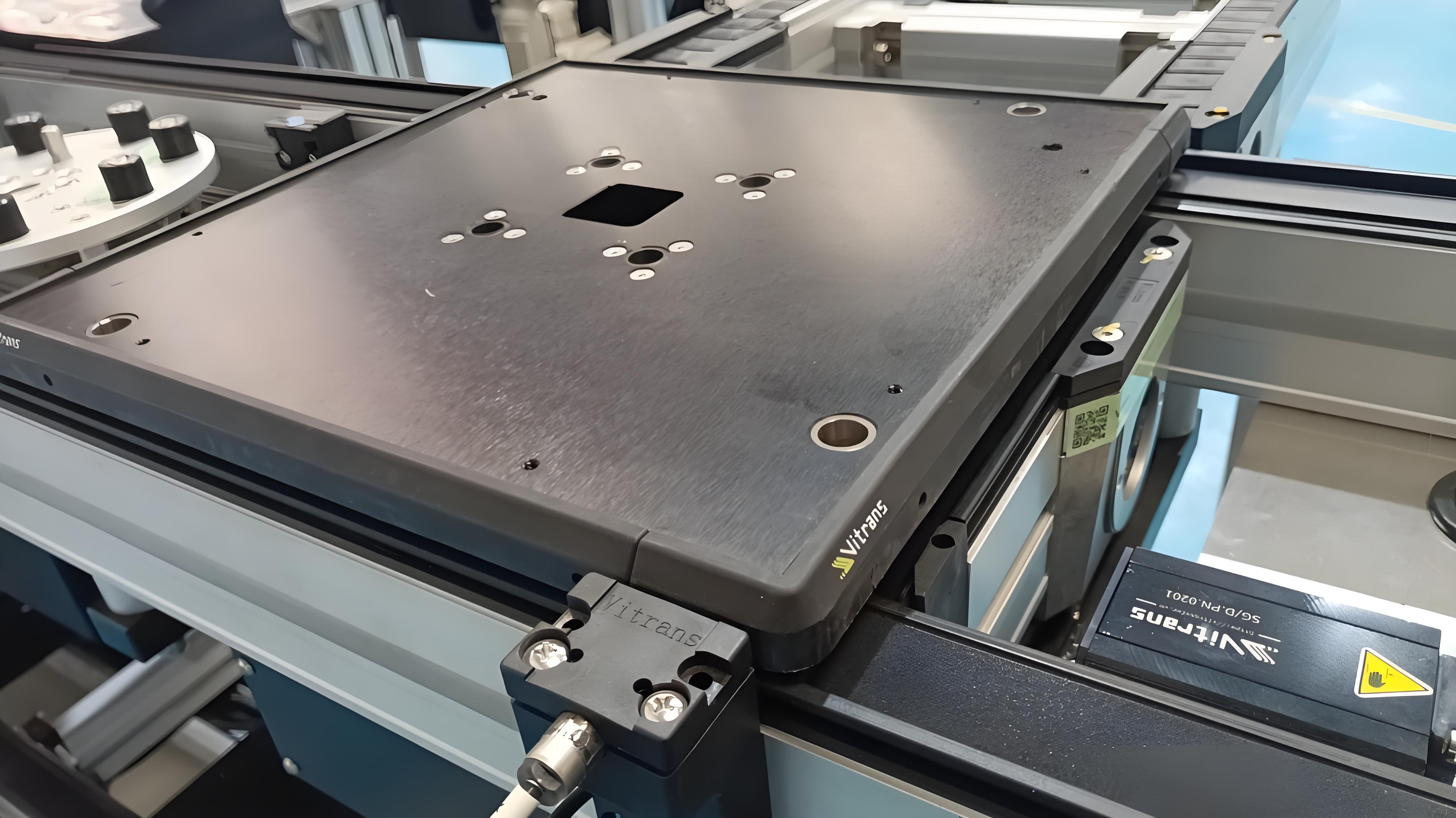

Horizontal circulation layout is to build a closed-loop conveying path in the same horizontal plane, the pallet loaded with workpieces flows along the preset line, and automatically returns to the flow after completing all the processes with modularized mechanisms such as bends, jacking and positioning, to realize the smooth operation of the whole process.

1,Core Advantages

Flow without return, efficiency高:Pallets are conveyed continuously along a closed-loop path without additional turnarounds or returns, which reduces wasted empty space, and is especially suitable for multi-process mass production, which can significantly shorten the operating cycle.

布The bureau is flexible and adaptable:Supporting the increase or decrease of workstations according to the capacity demand, no need to significantly change the line when expanding or adjusting the process at a later stage, friendly to small and medium batch, multi-species production scenarios.

Easy to operate and maintain:All the workstations are on the same level, so workers do not need to run up and down for operation and equipment maintenance, and troubleshooting can quickly locate the nodes and reduce maintenance costs.

Load adapted wide:It can be matched with BC2 (≤60KG) and FC2 (≤250KG),AC2/Hdoubled speed chainconveying line(≤2200KG) and other different load levels of the conveyor line, from light electronic components to heavy automotive parts can be adapted.

2,Applicable Scenarios

- Large-scale processing plants with sufficient horizontal space in the workshop and limited floor height (<4 meters), such as automotive parts assembly workshops and new energy battery module production lines.

- Mass production with ≥ 4 processing steps and little difference in the load of each station, e.g., assembly line for electronic appliances, production line for medical equipment parts.

- Hybrid production scenarios with high human involvement facilitate workers to quickly switch stations and collaborate on horizontal paths.

Two,Vertical Loop Layout

Vertical circulation layout builds a three-dimensional circulation path through the combination of upper and lower line body + elevator, the pallet is transferred between different levels with the help of elevator, and the pre-treatment, processing, testing, packaging and other processes are laid out in layers to maximize the use of vertical space.

1,Core Advantages

Space utilizationDouble:Vertical direction expands the conveying path and reduces the ground occupation of more than 50% than the horizontal layout, which is especially suitable for the scenario of small workshop area and sufficient storey height (≥4 meters), so that the small workshop can also realize high productivity.

The work process is clearly partitioned.No cross-interference: It can be arranged in layers according to the process priority, such as the upper layer is responsible for loading/pre-processing, and the lower layer is responsible for core processing/unloading, avoiding material congestion and personnel crossing between different processes.

Beat stabilization and high automation adaptability:Equipped with synchronous belt elevator (as fast as 500mm/s) and screw elevator, the vertical transfer is precise and efficient, and can be adapted to the high tempo.Automatic production line, reducing manual intervention.

Easy to manage:The line body is arranged in layers, the ground can be reserved for sufficient logistics channels, workshop 5S management is easier, but also reduce the risk of bumping in the material handling process.

2,Applicable Scenarios

- Small and medium-sized factories with tight horizontal space in the workshop and sufficient floor height, such as precision electronic component processing factories and small medical equipment assembly workshops.

- Production scenarios where work processes can be planned on a hierarchical basis without the need for frequent cross-layer collaboration, such as battery wafer processing lines (upper layer coating, lower layer cutting) and precision production lines for cell phone parts.

- High-capacity, fast-paced fully automated production, such as new energy sourcesLithium industryBattery PACK line, chip packaging and testing line, need to improve the overall operational efficiency through three-dimensional layout.

Three,3 core principles of layout planning

①Adaptation of site and load:First of all, clarify the workshop area, floor height, load bearing, heavy load (>250KG) priority selection of horizontal layout, light load, small space is selected vertical layout, to avoid exceeding the line load limit.

②Fit to the production beat:In the scene of many processes and slow beat, the horizontal layout is easier to optimize the distance between the workstations; in the scene of fast beat and high degree of automation, the vertical layout can reduce the intersection of processes and ensure continuous operation.

③Reserve space for expansion:Layout should be reserved for modular mechanism installation (such as bends, elevator interface), later capacity expansion or process upgrades, no need for large-scale transformation of the line body, reduce upgrade costs.

In conclusion. Pallet conveying lineThere is no universal template for the layout, the key is to fit their own workshop conditions, product characteristics and production needs. Wei ChuangPallet conveying lineSupporting a full range of modular customization, whether it's an open layout with horizontal circulation or a three-dimensional scheme with vertical circulation, it can be tailored to your actual needs.