In the manufacturing shop floor, a good assembly line is like the main artery of production, not only can connect the collaboration of man and machine, but also can flexibly adapt to the production needs of different products. Today throughWei Chuang AutomationPractical solutions in this field, starting with the classification and characteristics of assembly lines to learn more details about assembly line applications.

One,What exactly is a streamline?

The essence of assembly line is the efficient combination of man and machine, through the organic matching of conveying system, accompanying fixture, online special machine and testing equipment, to realize the smooth conveying of multi-species products. According to the division of conveying mode, there are mainly belt assembly line, plate chain line,doubled speed chainplug-in cables, mesh tape cables, suspension cables andRoller assembly lineSeven categories. Regardless of which type, the core contains traction parts, load-bearing components, drive devices, tightening devices, redirection devices and support parts of these parts, one is indispensable.

Its most popular point with organizations is its high scalability:

Conveying volume, conveying speed, assembly station can be customized according to demand, and can also be matched with auxiliary parts such as quick connector, fan, process signage, 24V power supply, etc., which can really be customized according to demand.

Two,not the samekindThe assembly line, eachspecificities

There are quite a few types of assembly lines on the market, and the key to choose depends on the product characteristics and production needs. Here to introduce you to the core features of the four commonly used types, combined with the advantages of Wei Chuang's products, to help you understand more intuitively:

1,Belt type assembly line

This kind of assembly line carries relatively light products and does not have much limitation on the shape. It can run in synchronization with the production line, and can also realize the climbing and turning, with the belt as the carrier conveyor, not only the noise is small, but also can complete the long-distance conveying of light materials.

Wei Chuang's matching work pallets are available in standard sizes from 160 x 160 to 800 x 800, and can also be customized on demand;Synchronous belt conveyor lineA single section can be loaded up to 60 kilograms, and the longest length can be up to 6 meters.平belt conveyorThere are also adapted solutions to meet the production needs of different light products.

2,doubled speed chainfunnelStreamline:

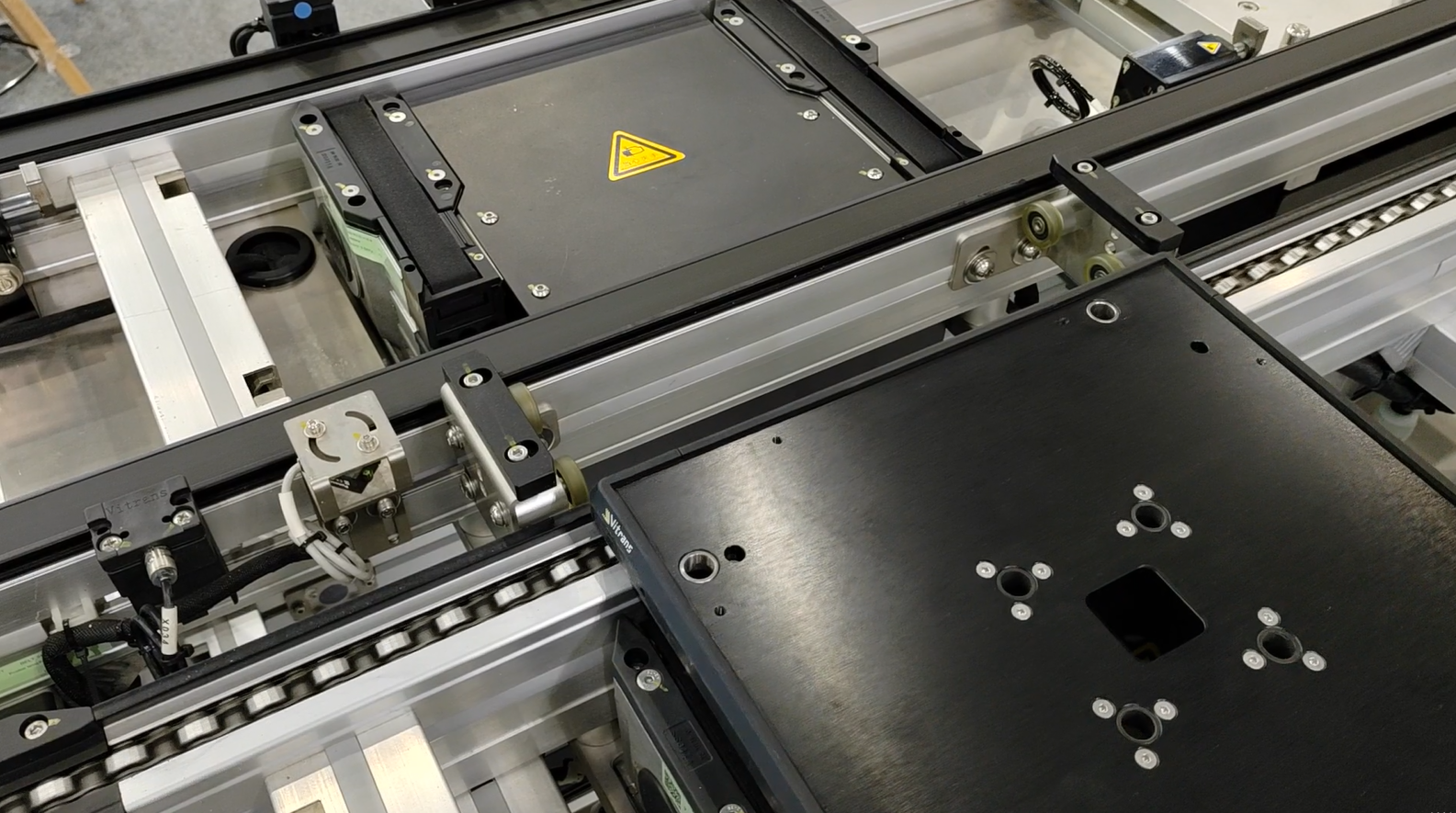

adoptiondoubled speed chainWith the traction of it, the workpiece plate can be transferred freely, and the workpiece can be started and stopped flexibly by the positioning of the blocker, and the two ends can be automatically jacked up and shifted across the transition. What's more convenient is that 90 degree/180 degree rotating device, special machine, testing equipment and manipulator can be added on the line or beside the line to adapt to the complex production process.

3,Drum type assembly line

It carries a wide range of product types, with few limitations. With the use of the blocker, it can realize the continuous running of the products, beat running and accumulation of the function; if you add the lifting and panning device, the product offline repair or testing, it will not affect the operation of the whole assembly line, which greatly reduces the risk of production interruption.

4,Plate chain assembly line

This type of assembly line is suitable for carrying heavier products, can run in synchronization with the production line, and can also achieve slope climbing. Although the production beat is not fast, but with the chain plate surface as the carrier, the conveying process is particularly smooth, suitable for the production of heavy products that require high stability.

About Wei Chuang Automation

In addition to adapting to different types of assembly lines, Wei Chuang's design in details is also very close to the actual needs of enterprises. For example, the work pallet is embedded with a positioning pin sleeve, with a positioning accuracy of up to ±0.5mm, which ensures accurate docking of the engine, chassis and other components in automotive assembly, directly improving assembly efficiency.

In addition, Wei Chuang also considers the long-term use of the equipment: for example, wear-resistant strips are installed on the edge of the guide rail of the conveyor line, which can not only protect the guide rail to reduce wear and prolong its service life, but also reduce the operating noise, making the workshop environment more comfortable.

IV. Conclusion

Whether it's long-distance transportation of light products, stable production of heavy products, or special needs for high cleanliness, the choice of an assembly line takes into account practicality and adaptability.

(reddish jade)The assembly line conveying solutions, from standard sizes to customized services, from basic functions to detailed optimization, are helping enterprises to solve the pain points in actual production, so that production efficiency is steadily improved.