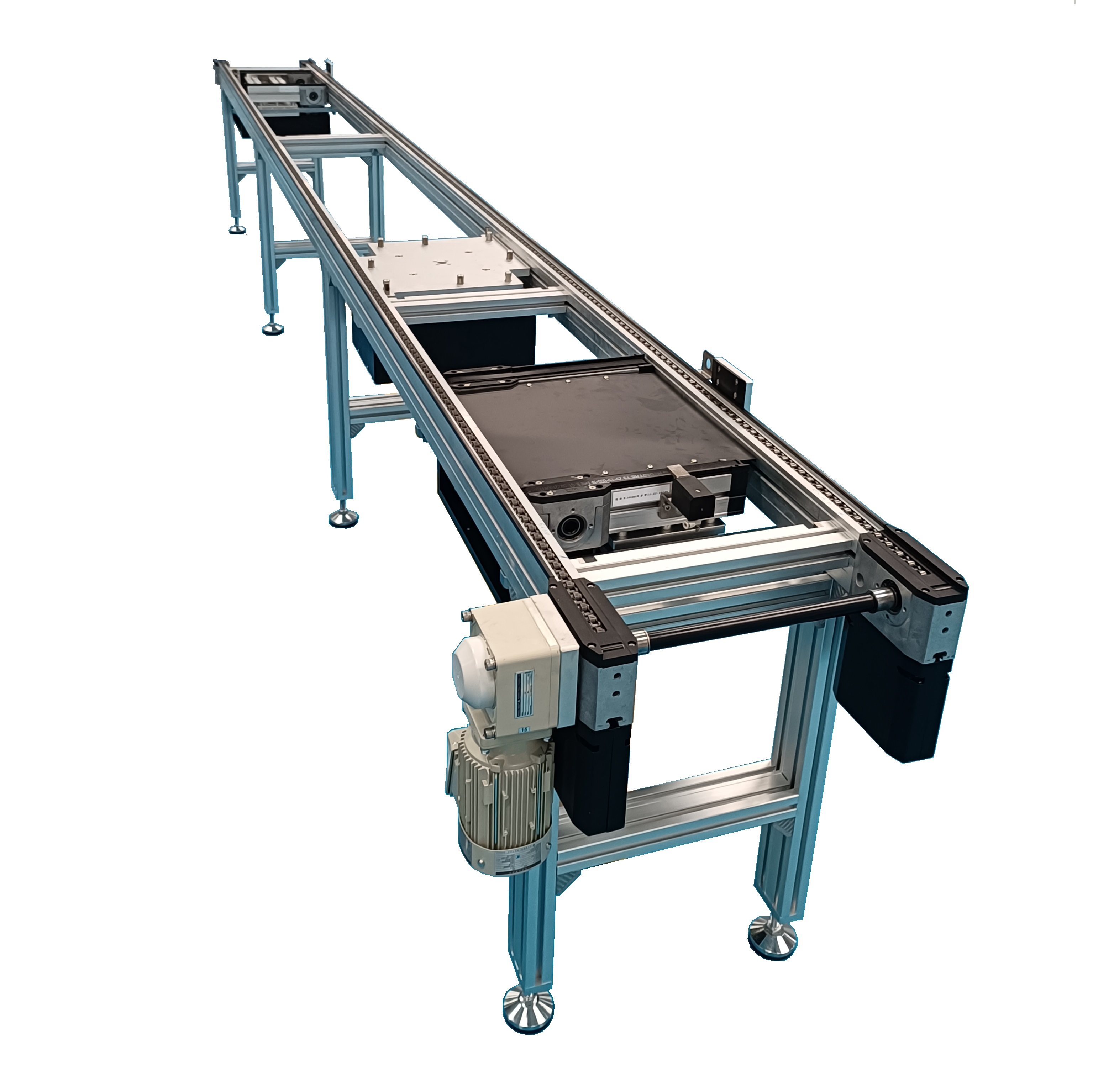

In today's automated production plants, palletsdoubled speed chainconveying lineLong ago is not a new thing, but gradually become the major factories layout production line when the priority choice. Many people may ask, this structure looks simple and simple conveyor line, what makes it widely recognized? Wei Chuang automation combined with many years of experience in equipment manufacturing and selection, today we will take you to understand in depth!Pallet Doubling Chain LineThe Charm:

I. On-site working condition measurement

First of all, from the most intuitive on-site performance. We have done a set of close to the actual production conditions of the actual test:

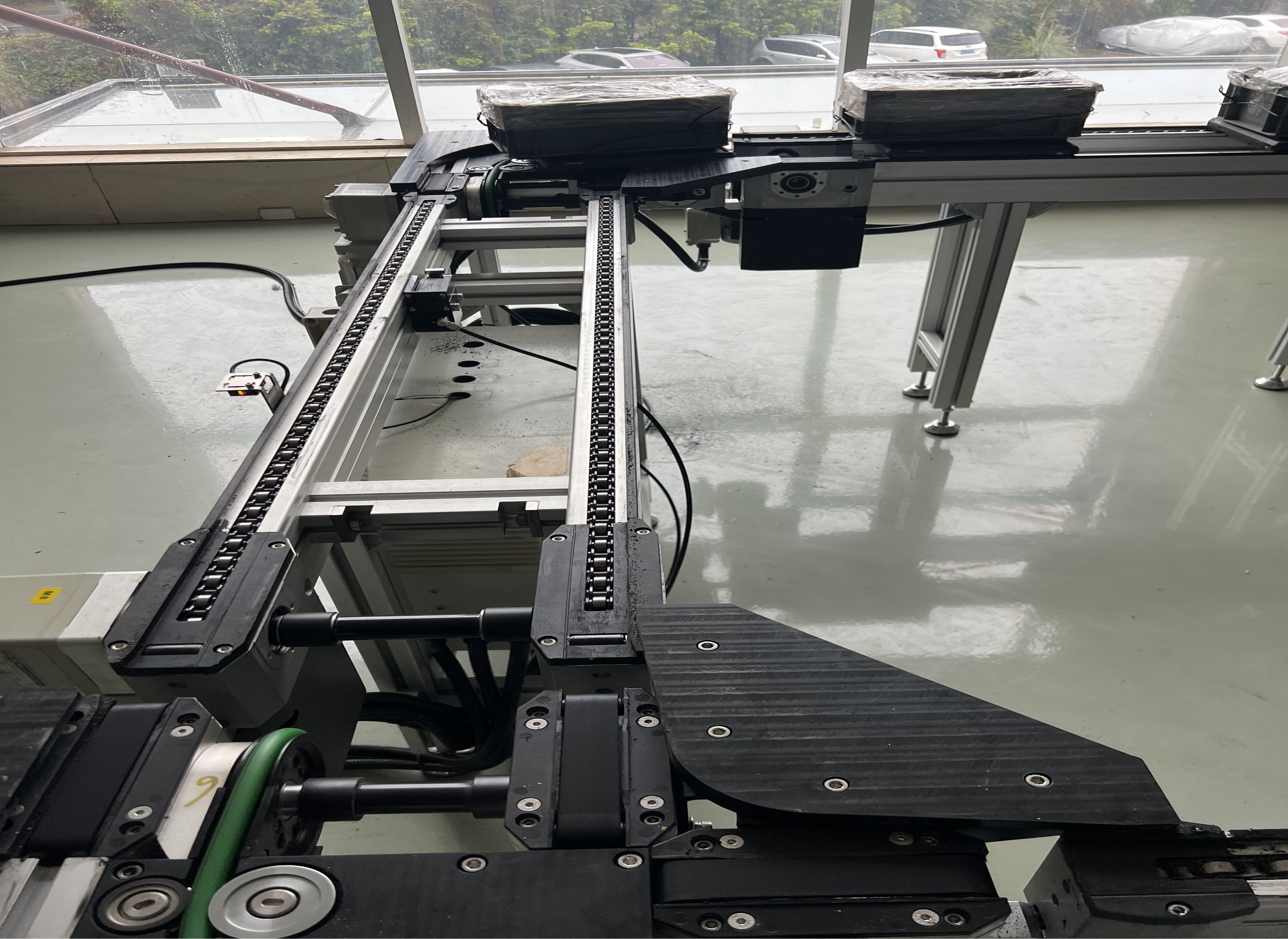

The 50 kg of material placed on the pallet to start the conveyor, and then gradually increase the size to 100 kg, 150 kg, and finally to 200 kg of heavy-duty status. Observe the whole process, the conveyor line always runs smoothly, the pallet moves without jamming or offsetting the situation. Particularly worth mentioning is the moment of shutdown - the tray can fall steadily into place, without the slightest rebound shaking, the noise during operation is also very well controlled. For us to do precision parts processing or assembly scenarios, this kind of stability is exactly the key to guarantee product quality.

Second, the core advantages of the speed chain conveyor line

Based on performance in live testing, thisSpeed Chain Conveyor LineThe core strengths can be summarized in three points, which are key to its ability to adapt to a wide range of automation scenarios.

1. Dramatic increase in durability

Its chain is integrated with an automatic tensioning mechanism, which can continuously maintain the optimal tension state without frequent manual adjustment. We have done a special test, after 1 million times of stopper cycle test, its performance degradation is much lower than the industry ordinary products, the service life has been extended by at least two times. Many factories have cooperated with us, this conveyor line has been running continuously for two years, and it still maintains the initial running accuracy and stability, which greatly reduces the frequency of equipment replacement.

2、Flexibility of layout adaptation

The conveyor direction supports free switching between forward and reverse direction, which is too important for production line planning. Whether it's connecting different assembly stations, testing equipment, warehousingSorting systemsThe newest version of the product is the one that can be quickly adapted without having to be reconfigured due to the limitations of the delivery direction.Production Line LayoutThe new system has significantly improved the compatibility and adaptability of shop floor equipment.

3. Advantages of silence and protection

By means of specially optimized tracksstructural designThe noise level of the equipment can be controlled below 65dB even when running at full load, which is in line with the requirements of environmental protection and occupational health of employees in the workshop. What's more, the pallet adopts a collision-free stopping design, which can effectively avoid the damage caused by the impact of the stopping moment on the material or precision parts, which is especially important in the high-precision production scenarios such as electronic components and automobile parts.

Third, choose Wei ChuangSpeed Chain Conveyor Lineunderlying causes

After communicating with hundreds of users from factories in different industries, I realized that users are interested in theWei Chuang AutomationThe focus of this conveyor line is centered on these three areas:

First, it's save and durable.More than 6 months of full-load durability test verification, so that the equipment failure rate than the industry's ordinary products reduced by 40%, reducing the impact of downtime maintenance on the production beat, which is the pursuit of high-efficiency production capacity of the factory is a direct benefit guarantee.

Second, professional security.The R&D team has more than 10 years of industry experience and more than 200 successful projects in different industries.Application CasesIt does not require us to spend a lot of time to verify the suitability of the equipment, which is equivalent to standing on the basis of proven experience to do the selection.

Third, fast response after-sales.24-hour after-sales response mechanism, an average of 2 hours to issue a solution, to avoid the embarrassment of equipment failure for a long time can not be resolved, which is to protect the production line continuous operation of the key support.

IV. Notes on selection:

To give you a few practical advice on selection, are summarized from the experience of many projects in the dry goods. Remember three key points when selecting a model:

① Define the load-bearing requirements of your own production, differentiate between light, medium and heavy load scenarios, and ensure thatconveying lineThe rated load capacity is matched to the actual working conditions;

②Secondly, verify the compatibility of the equipment and confirm the precision of the interface between the conveyor line and the existing production equipment and workstation layout;

③ Finally, we must pay attention to the after-sales response time, clearlyafter-sales serviceSpecific provisions of the guarantee.

Here is a special reminder, do not choose to save the initial cost of the product without a formal test report, such products are likely to have frequent failures in the later stages, the maintenance cost is often doubled, but the loss is not worth it.

Overall.Speed Chain Conveyor LineThe reason why it can become the first choice for automated production is that it accurately matches the factory's core demand for stable, efficient and flexible production. Selecting a suitable conveying line for the working conditions can lay a more solid foundation for the efficient operation of the whole production line. Who can refuse such a conveyor line?