Heavy-duty materials are dismantled and loaded again and again, and several units are loaded less a day; the conveyor line strikes twice in three days, and the maintenance fee is more than the earning; the workshop layout goes around and around, and the ordinary equipment simply can't be stuffed ......

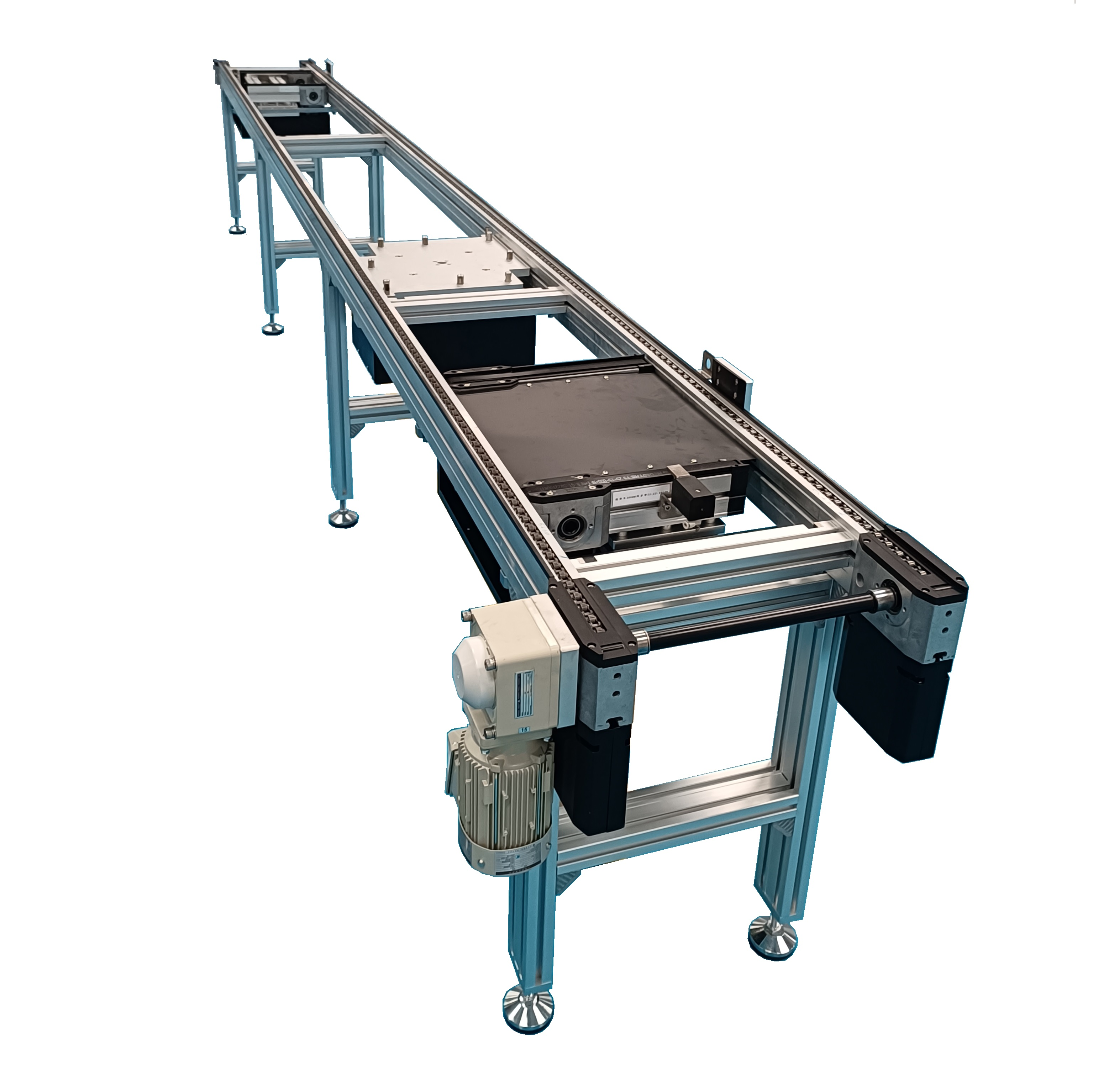

Many factory owners are in these conveying problems headache, in fact, industrial production has long given the solution -doubled speed chainconveying lineIt has been tested in countless automated factories. It has been tested in countless automated factories: from heavy-duty handling to complex layouts, from saving maintenance to improving efficiency, the advantages are demonstrated in real applications. TakeWei Chuang Automation的Speed Chain Conveyor LineAs an example, its main advantages and applications are as follows:

1、Super strong load-bearing capacity

The regular models can carry 700 to 2,200 kg, and customized models can achieve up to 4,000 kg if you have special needs. The reinforced profile frames with uniformly loaded pallets can be operated under full load without any deflection.

An auto parts factory before the 3000 kg engine block, ordinary equipment can only be disassembled into parts transport, and time-consuming and error-prone, less than 3 units per day, not to mention the scrap rate is also as high as 1.2%. Changing the customized modelDouble speed chain lineAfter that: the whole cylinder block is transported from the production plant to the assembly station in one go, so that 5 more engines can be installed per day, doubling the efficiency.

2、Extreme stability

After 10,000 hours of testing are not worn out, 24 hours of full load operation is no problem at all, continuous use of 3 years without failure, maintenance frequency can often be reduced to 70%.

Shenzhen, an electronics factory with its conveyor circuit boards, two and a half years of all-weather continuous rotation, frozen is not because of equipment failure stopped once; there is a machinery factory, before at least twice a month to maintain the conveyor line, change the speed chain conveyor line, half a year before the need for maintenance once, the order delivery rate of 85% directly soared to 98%.

3、Efficient conveying capacity

Not to mention the efficiency piece.Speed Chain Conveyor LineThe maximum speed can be up to 20 meters per minute, fast and slow can also be adjusted flexibly, accurate positioning, will not run off, so that the production process becomes more silky smooth.

Zhejiang, a small home appliance factory, before relying on artificial + ordinary belt line, a day at most 800 units of accessories sent; change thedoubled speed chainAfter a single day, the volume of delivery at once rushed to 1,500 units, the original two days of work in a day to get done, the order is not afraid of urgent production can not catch up.

4、Stable and durable

steel (bar, screw, product etc)roller chainWith a stainless steel frame, it can operate normally even in a high temperature environment of 150°C. It produces less dust when conveying, and it also comes with an anti-static design, so its service life is often three times that of ordinary equipment.

A hardware factory in Dongguan, the workshop is always 120 ℃ high temperature, before the conveyor line half a year to change a chain, times the speed chain used for 3 years is still smooth; Suzhou, a lithium power plant with it to transport the battery core, there has never been dust pollution or static electricity damage, scrap rate from 0.8% down to 0.1%.

5、Easy maintenance, save time and labor

In terms of maintenance of equipment.Speed Chain Conveyor LineThe material is durable, the structure is stable, the failure rate is very low, do not have to frequently overhaul, to a certain extent, can save a lot of maintenance costs and labor.

A machinery factory in Shandong before the conveyor line, every month to spend 2 days to maintain, change parts, adjust the parameters, both delayed production and money; change the speed chain, half a year only half a day of maintenance, maintenance masters no longer need to be around the conveyor line every day, each year may be able to save nearly 30,000 maintenance fees.

6. Highly customizable

With a maximum length of 30 meters, it can also be used in conjunction with hoists and jacking and traversing devices, and can be adapted to even the most complex workshop layouts.

An electronic factory in Guangzhou, the workshop is compact, there are many corners, the ordinary conveyor line can not be installed; customized with a turn module of the speed chain, and then with the lifting device to achieve the upper and lower levels of conveying, and at once more than 8 workstations to expand the production capacity of direct enhancement of 40%.

7. Wide range of application

Anti-static, clean, high temperature resistance these needs can be met, lithium-ion, automotive parts, 3C electronics, shoes, medical equipment and other industries, often can be used.

From heavy lifting to complex layouts, fromreduce costs and increase efficiencyto hassle-free maintenance.Speed Chain Conveyor LineThe advantages of the chain conveyor are never on paper, but are verified by countless factories with real money. If you are also for the production line conveying “delivery can not be, the old downtime, maintenance is expensive” these problems, may wish to reply to the [times the speed of the chain].(reddish jade)Send you complete cases of the same industry (including live video) and exclusive selection advice.