In modern production scenarios such as 3C electronics manufacturing, food processing, and automotive parts assembly, theContact belt conveyorAbsolutely indispensable and important conveying equipment. It doesn't have to be complicated, but it's a solid solutionmaterial handlingThe core needs of the transport stability, parameter flavor, cost controllable, which is also the most important three points when the enterprise selection equipment. Today from the core composition, key parameters, light and heavy load classification of these dimensions, with you to properly dismantle this industrial tool, to help you quickly find the one that is suitable for their own production.

I. Core components

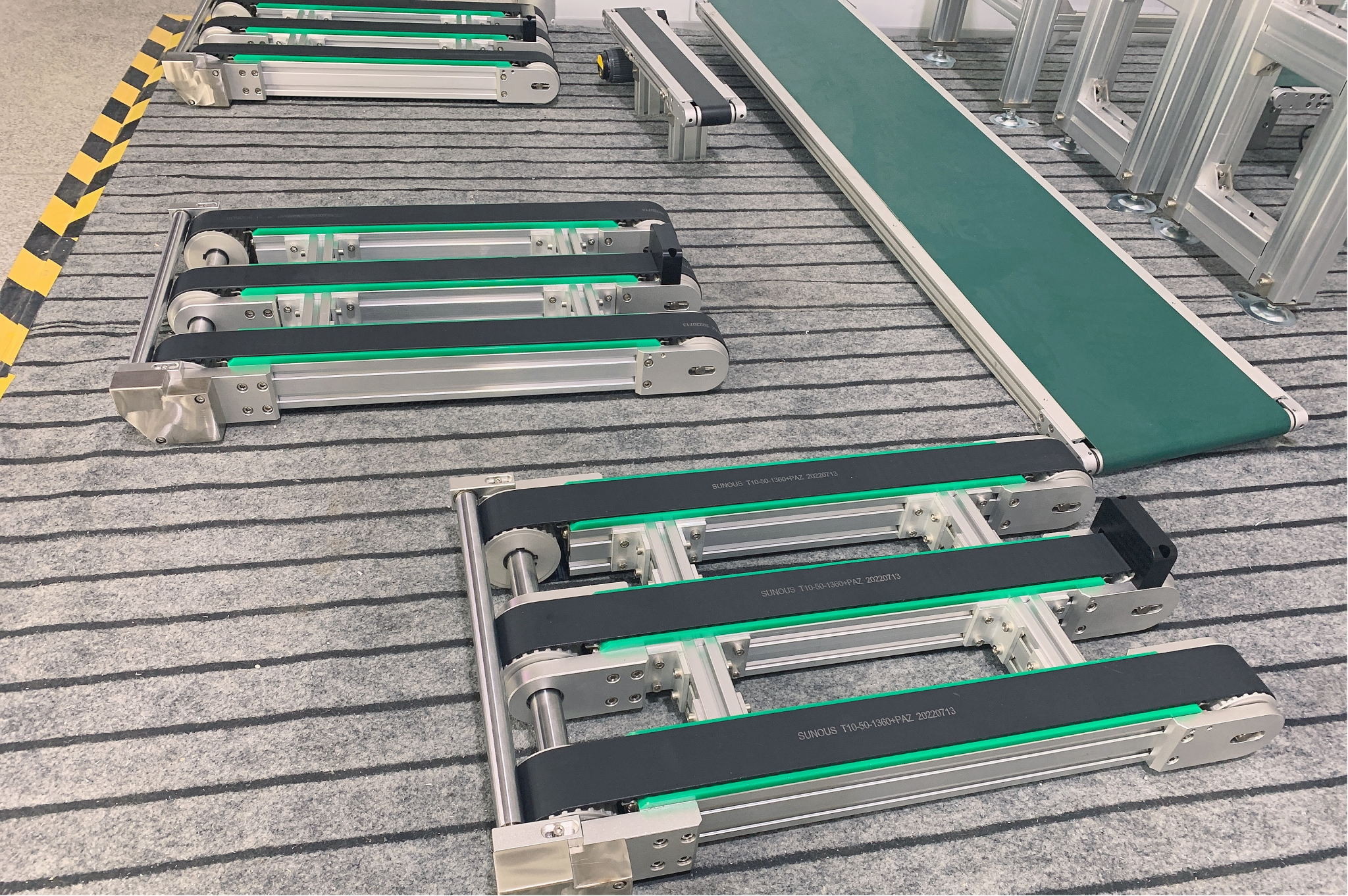

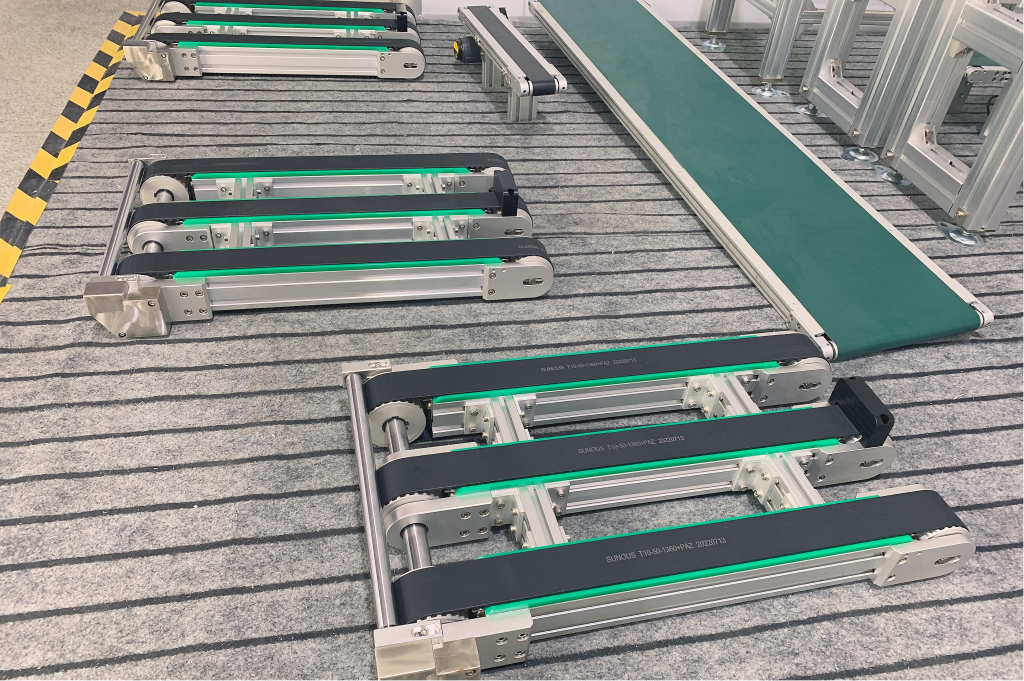

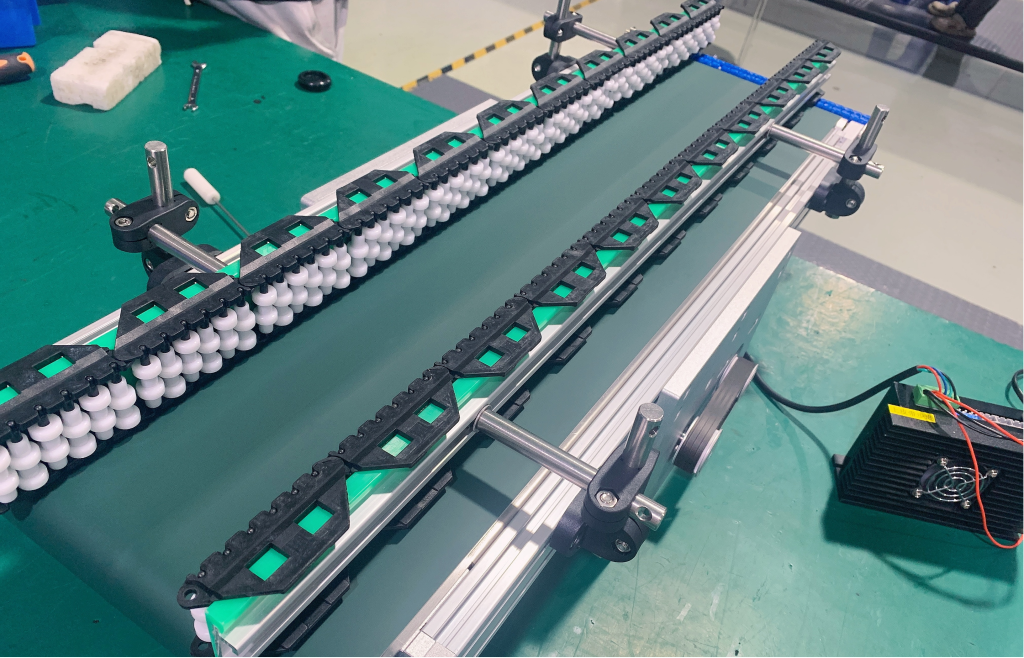

Contact belt conveyorThe reason why it can run reliably for a long time is the tacit cooperation of the four core components, the structure is not complicated, but accurately hit the demand point of industrial production:

- Drive pulleys (also commonly known as rollers):As the core of power transmission, the diameter ranges from 19mm to 80mm - for example, the diameter of the 30 series roller is 30mm, and the 80 series can reach 80mm, which can guarantee the smooth output of power, and with the curved roller design, it can also effectively prevent the belt from deflection, and reduce the loss of materials.

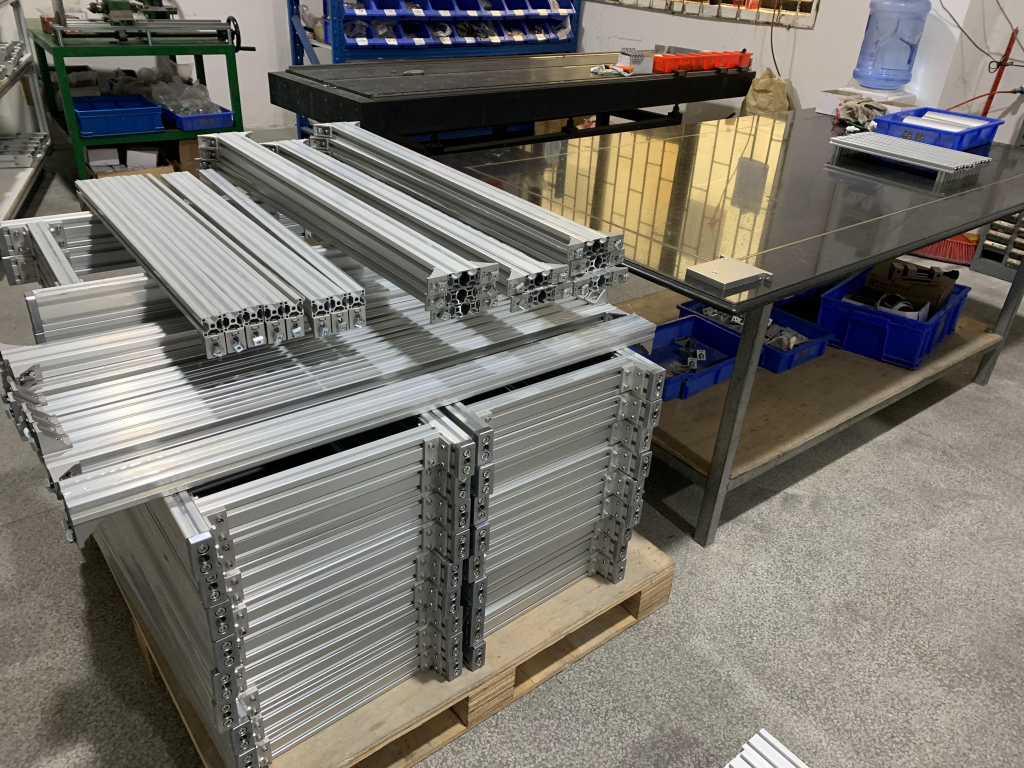

- Conveying profiles:There are three kinds of specifications: single slot, double slot and 3 slot, and their main function is to build a stable skeleton for the equipment. Single-slot profiles are suitable for narrow space scenarios, while double-slot or 3-slot designs can further enhance structural stability and adapt to different installation environments and load requirements.

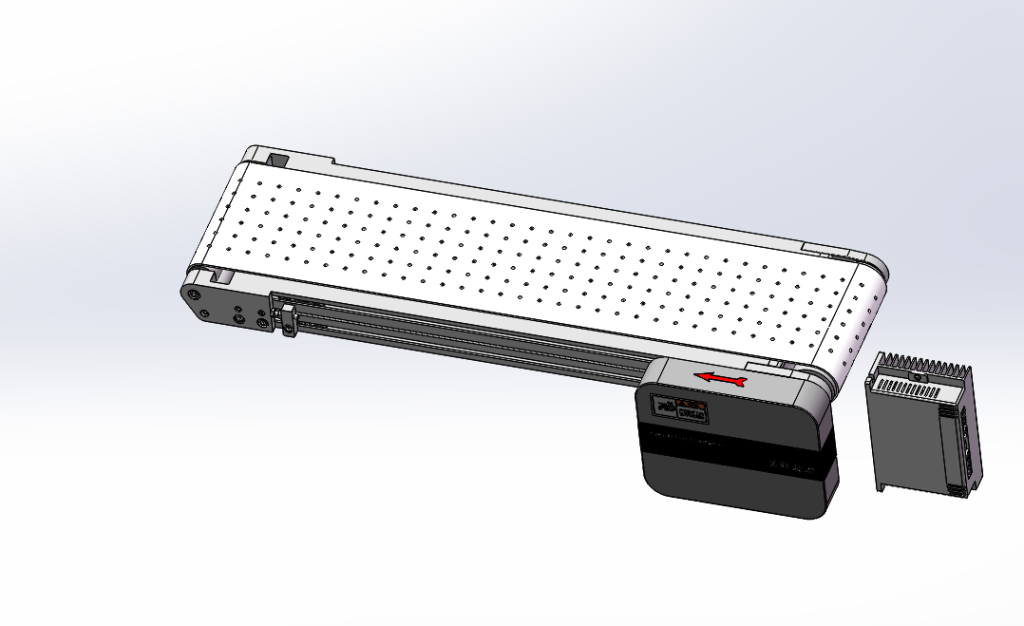

- Drive motor:There are two main types: external speed motors and built-in drum motors. Interestingly, the model with built-in motor will make the motor and conveyor structure into one, which is more resistant to interference and often better adapted to the layout of complex production lines.

- Customized belts:This part is very flexible, can be customized according to the needs of anti-static, food-grade materials, but also some models will be equipped with light-transparent belt, tooth surface cloth belt - for example, inspection models need to be light-transparent belt with the light source, the high demand for noise reduction scene is suitable for the tooth surface cloth belt.

Two,Key technical parameters

Selection of equipment before the parameters are hard indicators can not be bypassed - a direct decision on whether it can be adapted to your production needs, here to pick the key to say:

- Drive method:Optional speed-regulated motor drive ordrum motorThe drive, with speeds that can be adjusted on demand, can accommodate both slow-paced precision operations and fast-paced batch delivery.

- Size Flexibility:Conveyor widths from 50mm to 800mm and lengths from 100mm to 6000mm can be customized, with pulley (roller) diameters ranging from 1980mm, which are basically adaptable to both small electronic components and large industrial parts, regardless of whether the installation space is spacious or narrow.

- Load capacity:It covers a wide range of different needs, from light loads of 010KG (e.g., tiny parts transportation) to heavy loads of 100200KG (e.g., heavy parts transfer).

- Running speed:1068m/min is adjustable, slow speed is suitable for scenarios that require precision operation, while fast speed can directly enhance the conveying efficiency and make the production process more silky smooth.

Three,Classification of light and heavy loadsselection

So many models, in fact, according to the load requirements of a class, the selection is very intuitive, we might as well look at these three categories:

Light Duty Series (30/40 Series)

- Core parameters: load 030KG.platenDiameter 3040mm, width 50400mm, speed 1030m/min

- Scenario: Suitable for those small and lightweight materials, such as short-distance conveying of 3C electronic components, precision transfer in watch manufacturing, and conveying of small medical consumables. Even if the installation space is narrow, it can be adapted flexibly without occupying space.

Medium Load Series (60 Series)

- Core parameters: load 0100KG, drum diameter 60mm, width 80800mm, speed 1060m/min

- Applicable scenarios: more often used in daily production, to meet the demand for medium loads, such as electronic equipment assembly lines, automotive parts of the pallet transfer, and food processing in the category sorting (with customized baffle is very suitable), taking into account the efficiency and stability.

Heavy Duty Series (80 Series)

- Core parameters: load 0200KG, drum diameter 80mm, width 100800mm, speed 1268m/min

- Applicable Scenarios: For high-intensity industrial needs, such as 3C heavy-duty parts transportation, large-scale precision instrument handling, heavy-duty pallet transfer. Equipped with industrial grade motor and triple safety protection, it can run stably even under high intensity working environment.

One,Common strengths across the range

In addition to targeted adaptation to different scenarios.belt conveyorThere are also some generic additions across the range:

① Practical function: most of them are equipped with anti-running design, modular structure, support customization with or without border, and simple post maintenance without too much effort.

② Flexible material: the belt can be customized according to the needs of anti-static, food grade, translucent type can be done, especially in the food industry, direct contact with food can be specially customized.

③ Powerful delivery: as long as the order quantity ≥ 10 units, the delivery time can be controlled within 7 days, do not have to wait too long to put into production, without delaying the production schedule.

④Wide range of adaptations: from tiny electronic components to heavy industrial parts, from inspection processes to sorting scenarios, basically covering most of the industrial production needs.

Actually, the choice ofbelt conveyorNo need to get entangled, the core is to see if the load, size and production scenario match. Whether you need precision conveying for light loads or efficient transfer for heavy loads, this equipment can meet your needs through precise parameters and customized design. If you want to measure the selection according to the specific scene, feel free to consult, and we will find the most suitable conveying solution together.