01

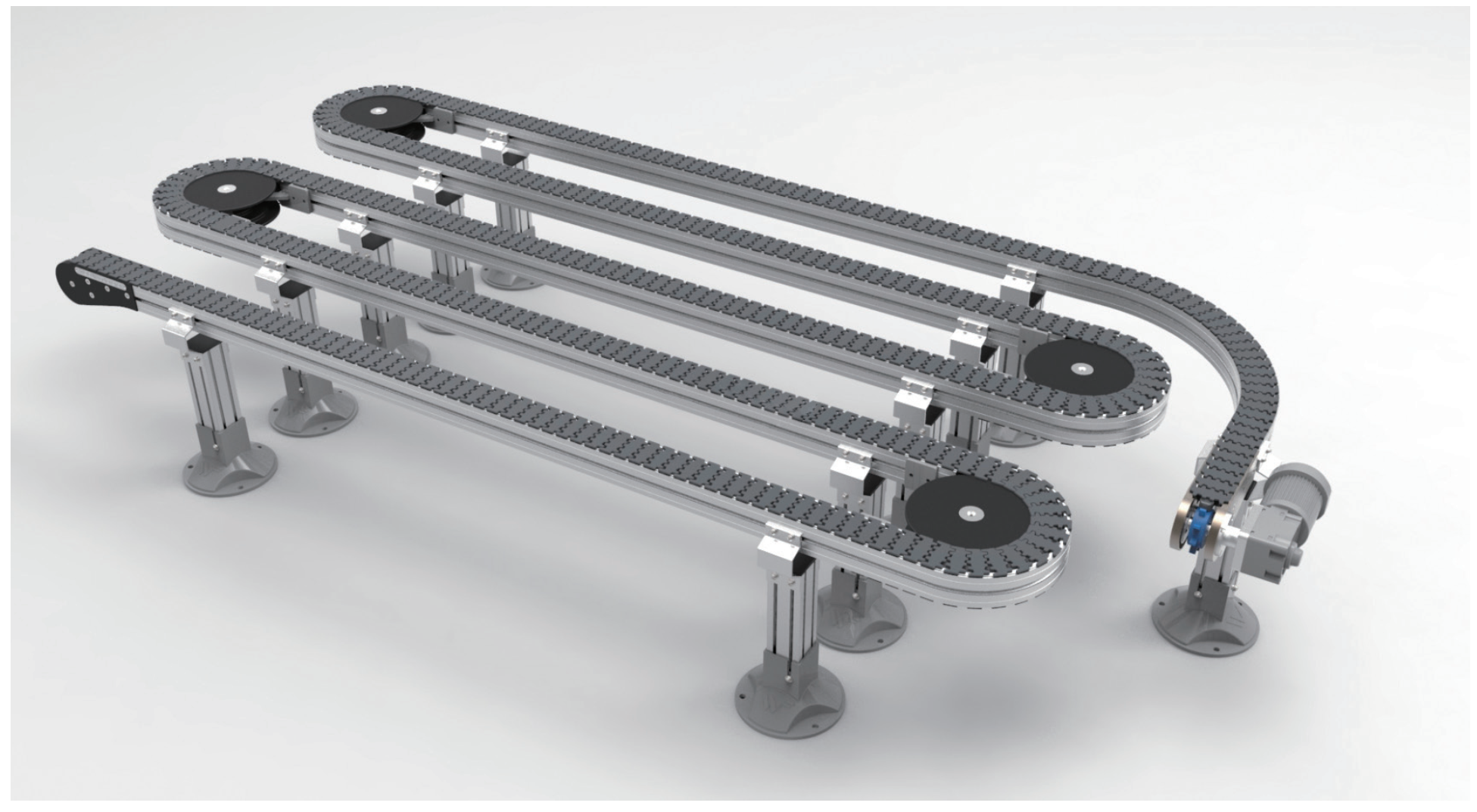

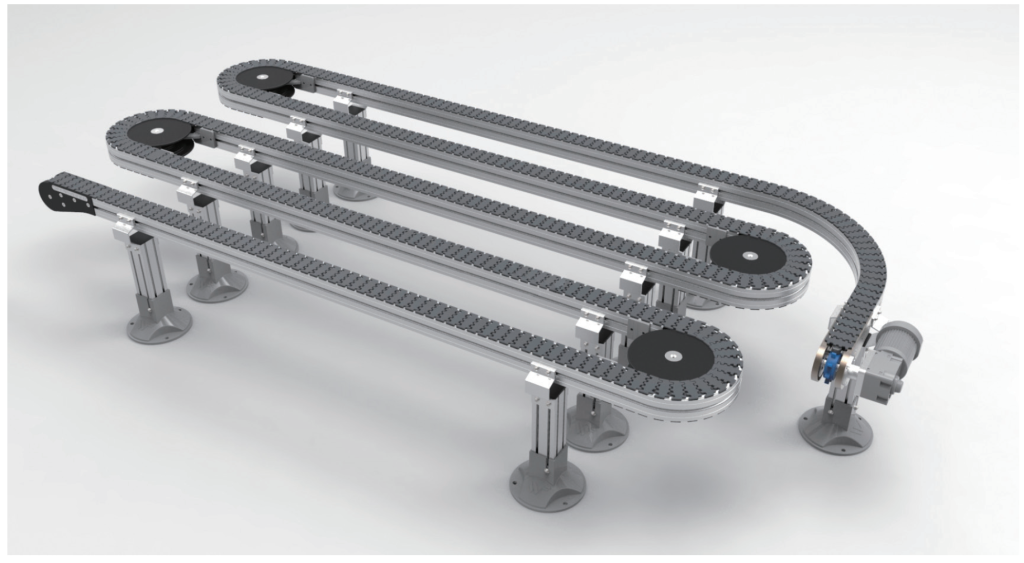

flexographicchain conveyor的conceptual

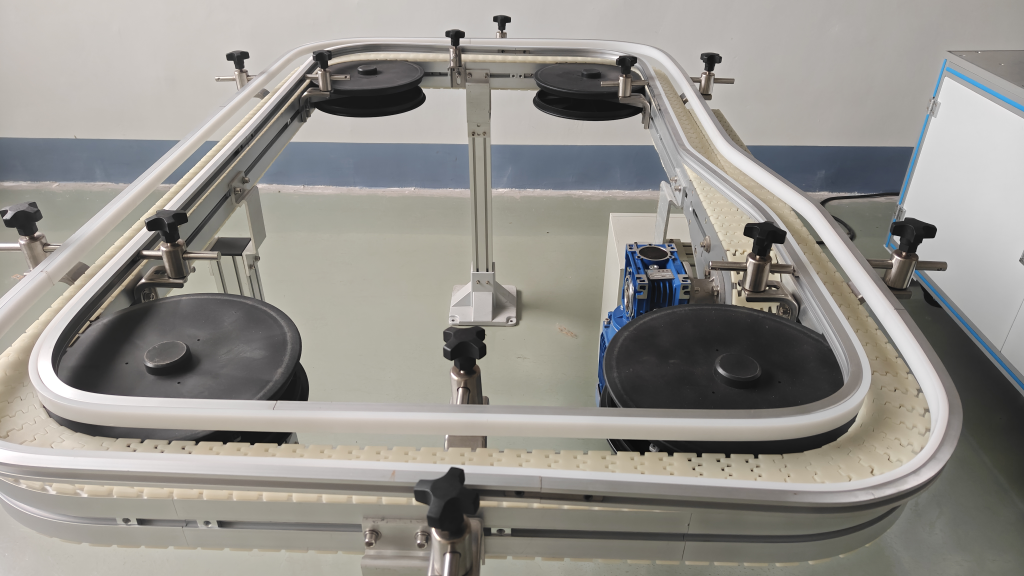

Flexible chain conveyor lineIt is a type of conveyor consisting of a conveyor beam made of aluminum profiles, support legs made of aluminum profiles, high-pressure die-casting aluminum drive modules, turning aluminum profiles and chain plates.

Because the conveyor beam and support legs and other parts are aluminum profiles, it is easy to cut quickly, easy to be long or short, high or low, at the same time, aluminum is easy to bend, easy to modify the length of the line and the height of the line body directly at the installation site, the weight of the aluminum profiles is lighter, easy to make the required path of the conveyor line, so it is called the flexible chain plate conveyor line.

02

Main structure and composition

①conveyor chain:Made of high strength engineering plastics. The conveyor chain utilizes the well-designed mutually staggered give way structure and hinge fit between two links, which enables the conveyor chain to turn freely in the horizontal and vertical directions, thus realizing the whole conveyor belt to turn in space.

②transfer beam:Constructed of aluminum alloy profiles with anodized surfaces or stainless steel and friction slides.

③Carrier:It also consists of aluminum alloy profiles or stainless steel with anodized surfaces.

④drive unit:It consists of aluminum drive head and tail die-cast by powder metallurgy process. Divided into single drive, double drive and intermediate drive.

⑤guide:Two side guards that keep the material running in the middle of the chain plate at all times.

⑥Turning device:Internal support device for chain plate turning. It is divided into horizontal elbow, vertical elbow, horizontal wheel elbow and horizontal wheel.

03

Flexible Conveyor Linecharacteristics

Feature 1:Compact, lightweight and beautiful

Feature 2:Standardized structure, fast installation, stable system

Feature 3:modular designThe modular design allows for the shortest possible time to establish the functional needs required by the customer's production line, and the conveyor equipment can be reused.

Feature 4:Compact, quiet, non-polluting, mostly used with production lines with high hygiene requirements, small site coverage, cleanliness and high automation.

Feature 5:It can be big or small, freely expandable and easy to operate, and can be made into a variety of conveying methods, including material collection, diversion, inspection and merging functions.

Feature 6:Small turning radius, strong climbing, widely used in production scenarios that require a variety of assembly forms.

04

Advantages and Applications of Flexible Conveyor Lines

Flexible chain conveyor lineFlexible layout, space-saving, and a wide range of specifications can be selected according to the conveying materials and process requirements, to meet the different needs of various industries:

→ The conveying surface is flat and smooth, low friction, smooth material transition, low maintenance, low running cost, so it can convey all kinds of glass bottles, PET bottles, cans and other materials, and can also convey all kinds of bags;

→ Can be directly rinsed with water or directly immersed in water, and in line with the hygiene requirements of food production, clean and non-polluting, to meet the requirements of the food and beverage industry on health;

Therefore, flexible chain conveyor lines are widely used in food, beverage industry, toilet roll paper conveying, cosmetic industry, tobacco manufacturing, motor manufacturing, machine parts and other industries.