7 Principles of Workshop Layout

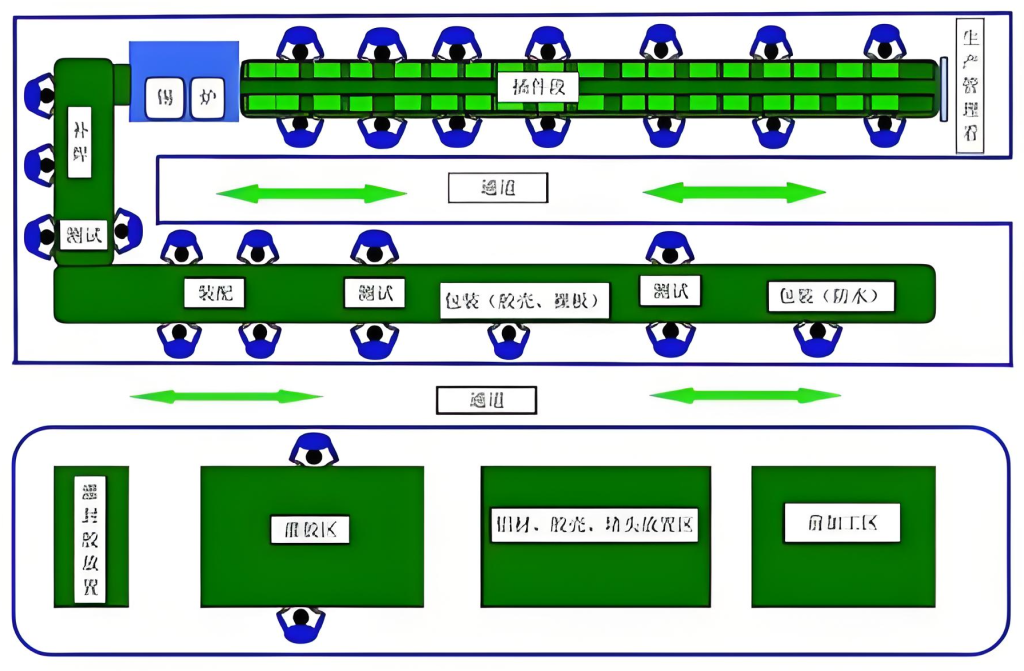

01the principle of fluency

Organic combination of the processes, the principle of concentrated placement of related processes, the principle of flow layout

02shortest distance principle

Keep handling distances short, processes can't cross, run in a straight line

03balance principle

Resource allocation between workstations, rate allocation as balanced as possible

04fixed-cycle principle

Non-value-added activities such as handling and passing are best kept to a minimum.

05Economic yield principle

Adapt to the smallest batch production situation, use space as much as possible, do not let the materials and equipment littered, and reduce the floor placement.

06Principles of Flexibility

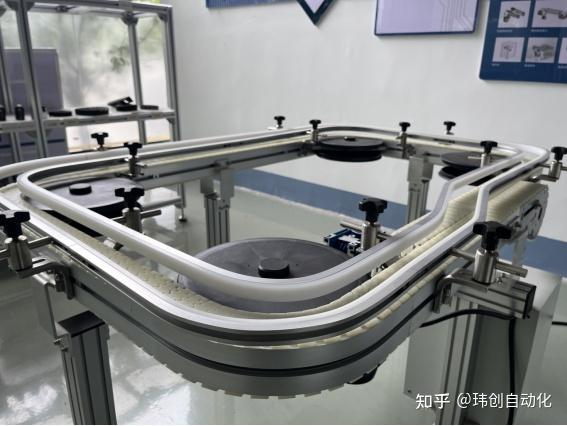

The space layout should be fully adaptable to future changes, if it is a small batch of many kinds of products, give priority to the "U" line layout, circular layout and so on.

07Principles of error prevention

Error prevention is the number one priority when it comes to production layouts. The first step is to prevent errors in the hardware layout to reduce production losses.

" Factory Production Layout PursuitWhat is the goal of the

To put it bluntly, it is to make the material handling costs to a minimum, space, labour can be fully utilized, but also to facilitate the workshop head between employees, employees and managers, employees and users of information communication.

" How can these goals be achieved?

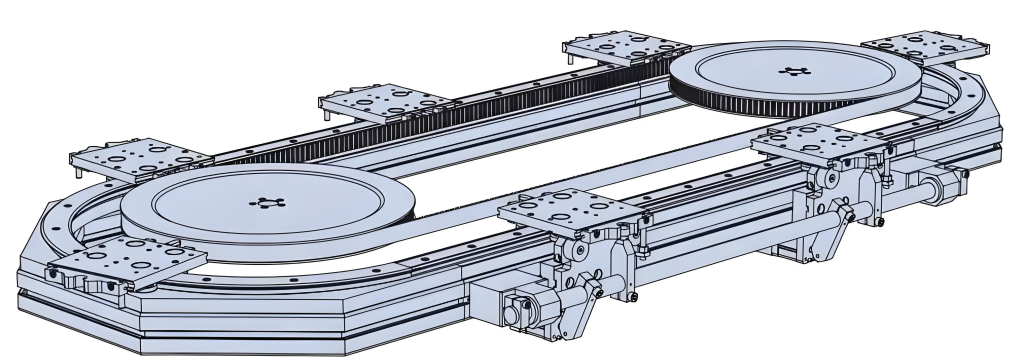

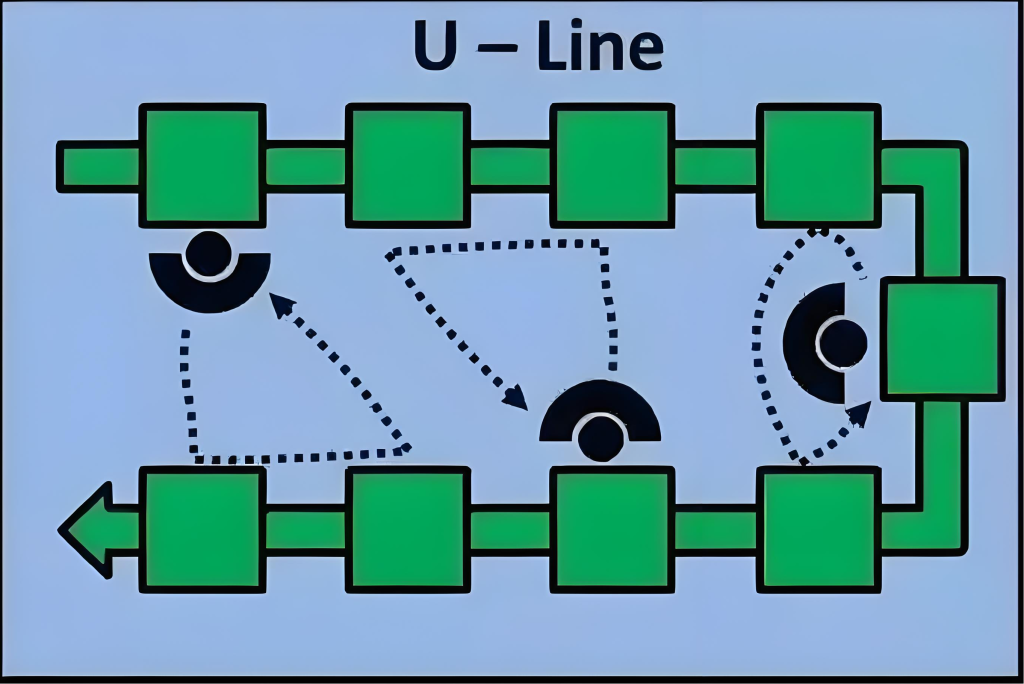

The best way is to set up the equipment into a "U" shape, to engage in "a flow" production.

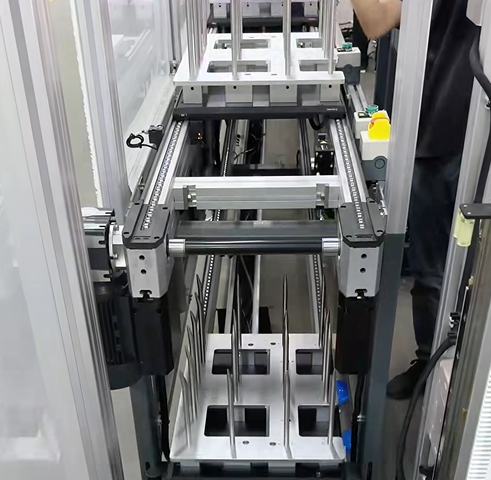

"A flow" production, that is, the product in the production process as much as possible small batch rotation, preferably a single piece of flow, so as to reduce the number of work in progress, to avoid production line waste. Previously, the traditional "one" type production line, equipment according to the order of processing lined up, looking quite neat, in fact, there are many shortcomings. A person to operate multiple devices, have to go back and forth, laborious and increased labour intensity, flexible adjustment of personnel is also difficult.

On the other hand, in a "U" arrangement, the exit and entrance of the production line are in the same location, and one machining position may contain several processes. Therefore, the U-shaped arrangement requires the development of versatile workers. However, there are also many benefits, reducing the waste of walking, the number of workstations, shortening the cycle time, improving efficiency, and fewer operators, the cost will naturally come down.

In short, grasp these 7 principles, optimise the layout of the assembly line, manufacturing plant production road will go smoother and smoother, the more stable.