Description

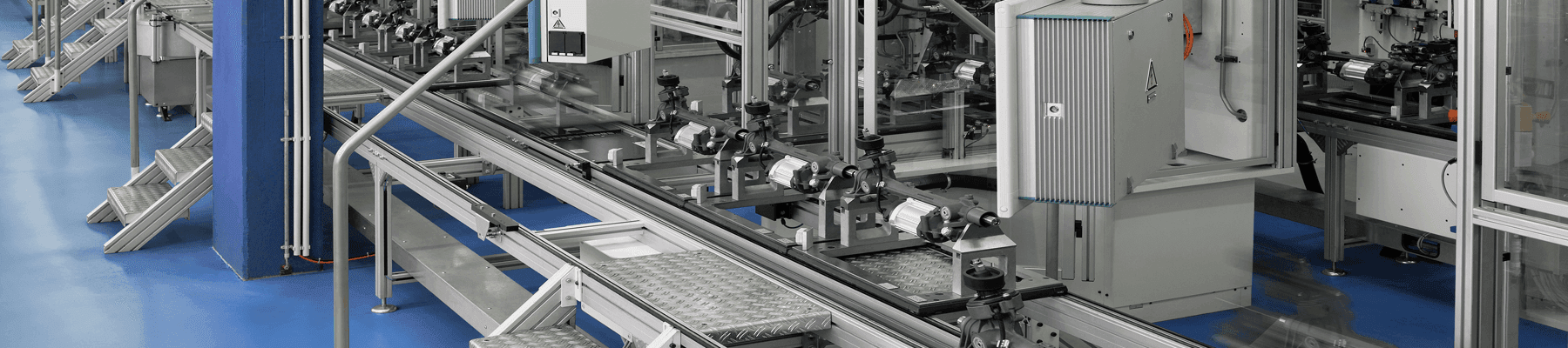

PC2 High Clean Overhead Chain Conveyor Line

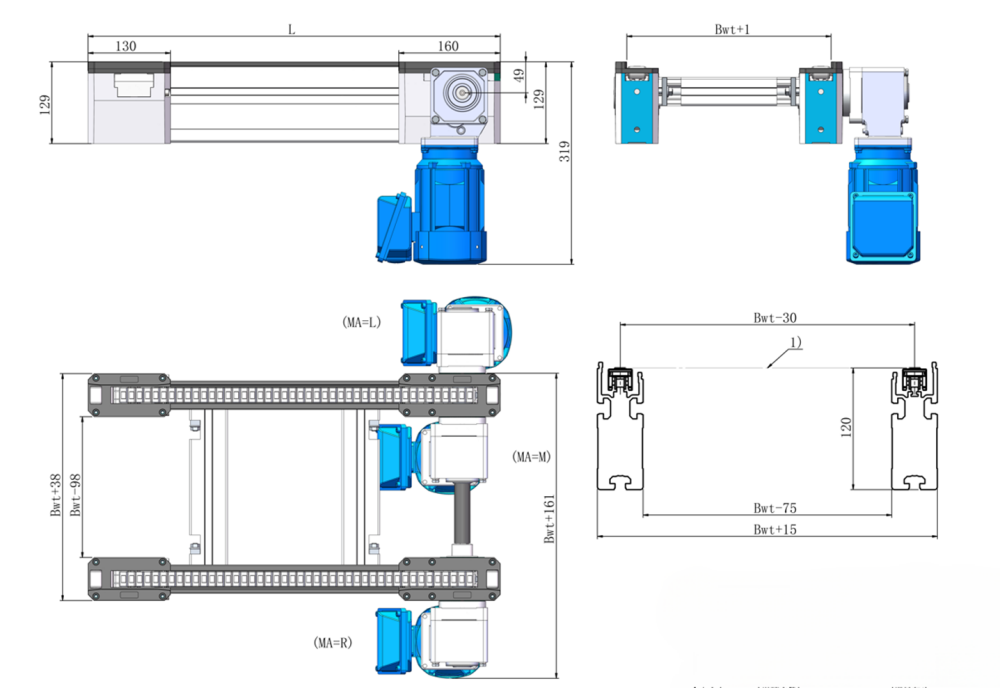

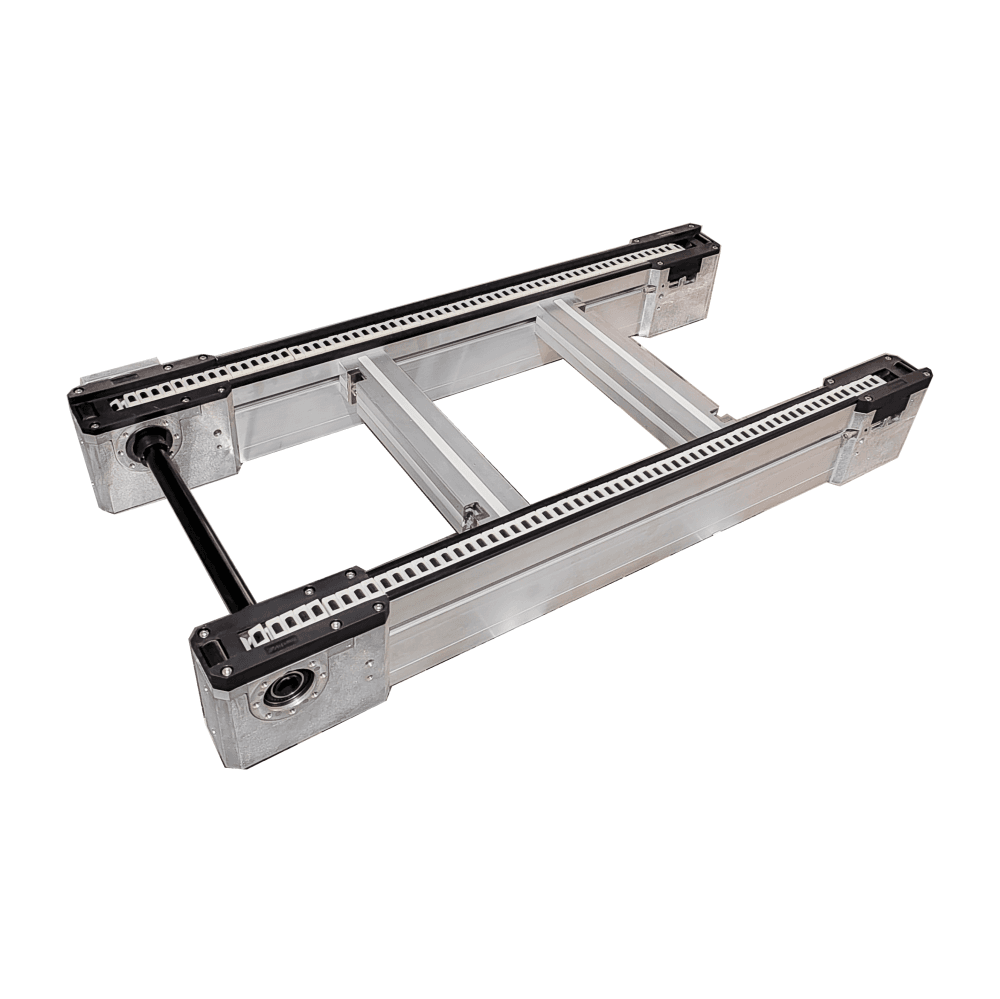

- Transmission medium : Dedicated Top Chain

- Width of pallet in transport direction. 160, 240, 320, 400, 480, 640, 800 (160 ≤ Bwt ≤ 800)

- Conveying line length/Mm : 500≤L≤8000

- Nominal speed (m/min). 6, 9, 12, 15, 18

- Maximum load/kg. 200

- Driving method : Three-phase motors

- Motor mounting method : L, R, M

- 电机安装方向 : 0°, 90°, 180°, 270°

- Voltage /V : 220/380 AC

- Frequency /Hz : 50

- Motor Connection : junction box

key function

- Dust reduction technology:Plastic chain conveyors are equipped with features specifically designed to minimise dust generated during pallet transport. This is vital for industries that require a clean and controlled environment.

- Precise control: Benefiting from precise control of pallet movement, the plastic chain conveyor ensures accurate positioning and smooth transitions throughout the entire conveying process.

- Low Maintenance:Plastic chain material reduces wear and tear compared to conventional conveyors, resulting in lower maintenance requirements. This helps to extend the life of the system and improve operational efficiency.

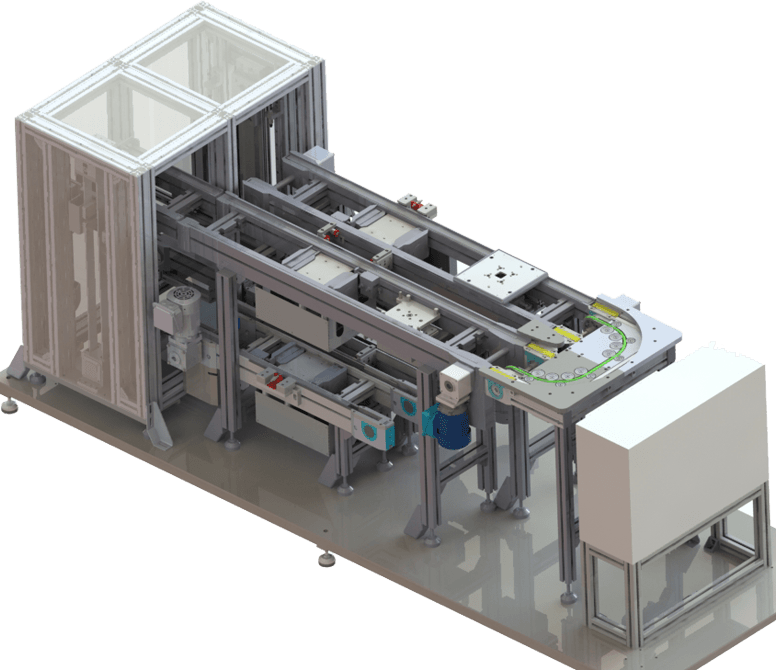

- Modular Design:Our Pallet Conveyors The system features a plastic chain conveyor with a modular design for easy configuration and adaptability to a variety of material handling needs.

- Quiet operation:Plastic chain conveyors reduce noise levels for a quieter working environment. This is particularly beneficial in environments where noise reduction is a priority.

- Seamless Integration:The system integrates seamlessly into a variety of production setups and is compatible with other automation equipment to ensure a smooth workflow.

mileage

A. Dust-free material handling

B. Precise positioning

C. Reduced maintenance

D. Modularity and adaptability

E. Quiet running