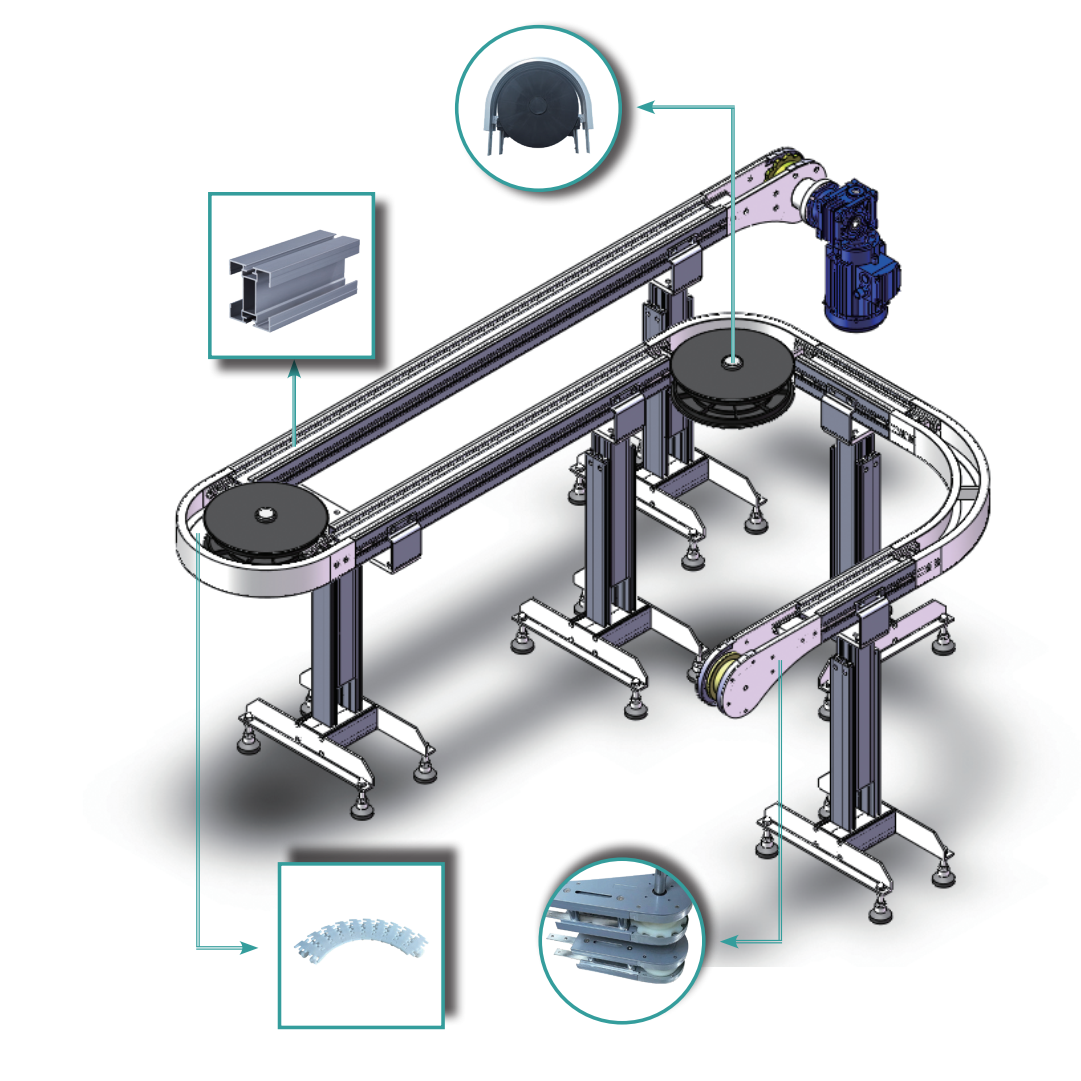

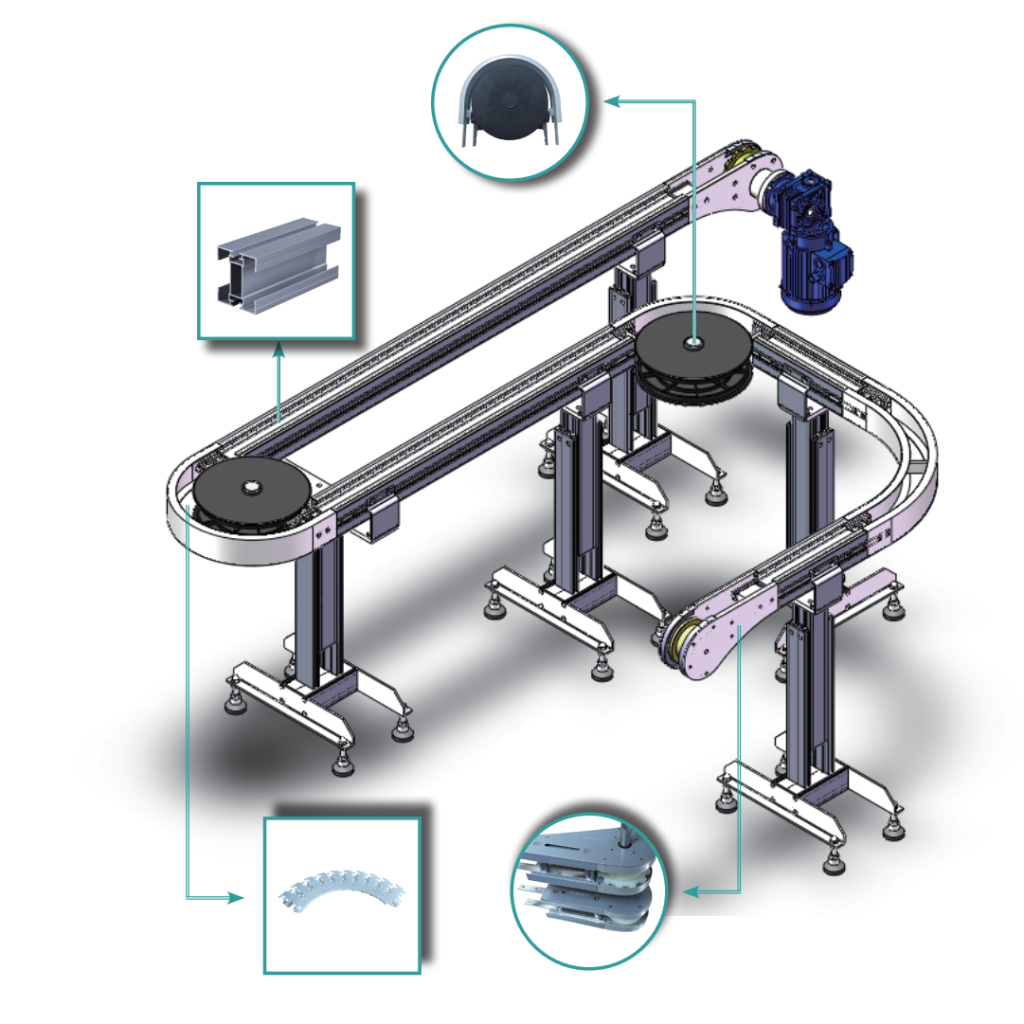

Flexible chain conveyor lineIt is a device used for material conveying, which consists of a series of bendable chain plates attached to a chain. These chain plates can move horizontally, vertically and diagonally to achieve material conveying and transfer.

I. Characteristics of Flexible Chain Conveyor Line

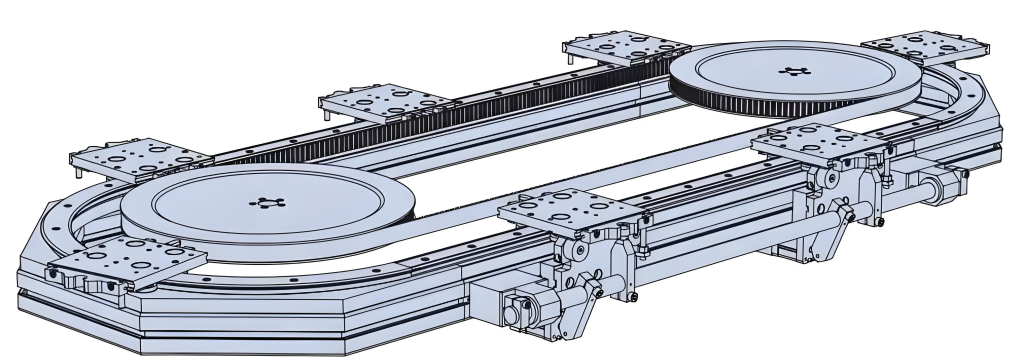

Multi-dimensional delivery capability:Complex paths such as straight-line conveying, climbing and lifting, 90° horizontal turns, and even switching between 5°-90° vertical bends, with a minimum turning radius of only 150mm, make it easy to navigate through narrow workplaces.

Efficient and stable operation:Maximum conveying speed up to 50m/min, and in the transition of the curve needs to be reserved straight section buffer, to ensure that bottled drinks, boxed snacks and other products smooth transition, to prevent tipping and slipping.

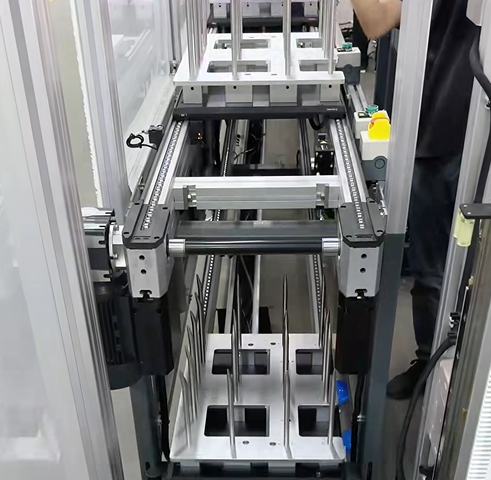

Modular structure advantage:Conveyor beams with widths ranging from 45-300mm and single lengths of 3m can be quickly assembled like "building blocks" to form a 100-metre production line, which is suitable for different production capacity requirements.

II. Main advantages

Flexible layout design

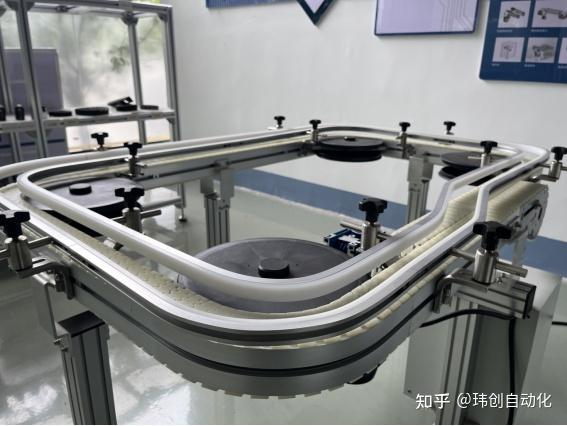

As a model of modular design, theFlexible chain plate lineComposed of independent parts, it has simple and lightweight structure, convenient assembly and easy maintenance. It can flexibly adjust the conveying line according to the layout of the food production workshop and the change of the production process, and easily realise multi-level and multi-angle conveying such as horizontal, inclined, turning, etc., so as to satisfy the diversified production demands of food enterprises.

Quality materials and performance

The chain plate is made of high quality material with good wear and corrosion resistance, flat and smooth conveying surface and low friction. This makes it able to ensure the smoothness of conveying when conveying column-shaped tray cups, all kinds of bottles and box products, without causing damage to the products, ensuring the integrity and safety of food in the conveying process, which is widely used in food and beverage, daily chemicals, pharmaceuticals, automotive parts and other industries, and the food industry has very high requirements for the stability of the conveying equipment, and the qualities of the flexible chain plate line just fit this demand.

Three,Reasons for the wide range of applications in the food industry

1.Clean and environmentally friendly, in line with food industry standards

The food industry has extremely strict requirements for hygiene in the production environment, and theFlexible chain plate lineAssembled with white high strength engineering plastic chain plate and anodized aluminium alloy frame, the chain plate is pure white, non-corrosive, non-rusting, no need for lubrication, avoiding oil contamination, and in full compliance with GMP specification. This provides a clean and safe conveying environment for food production, effectively prevents food from being contaminated during conveying, and guarantees the quality and safety of food.

2.Quiet operation and reduced noise disturbance

In food production plants, especially in noise-sensitive areas, the quietness of the working environment also affects productivity and the working conditions of employees.Flexible chain plate lineOperating sound is less than 30 decibels, which is close to the library ambient noise standard, and the noise level is so low that there is virtually no noise disturbance to the working environment.

3.Stable and reliable conveying performance

The conveying of foodstuffs often involves products of various shapes, sizes and weights, which places high demands on the stability and reliability of conveying equipment.Flexible chain plate lineThe chain plate is made of modified polyacetal resin (POM), and the pin is made of S5304 (stainless steel), which is durable and has a stable mechanical structure to ensure that the conveyed products do not fall over and slip, especially suitable for conveying precision parts, fragile products or liquid containers, which provides stable and reliable conveyance for food packaging and sorting, and effectively reduces the rate of loss of food products in the process of conveying.