In the automated production of new energy, medicine, food and other industries, it is especially important to choose the right conveying equipment. Flexible chain conveyor system is suitable for high cleanliness, small site, high automation production needs, but many people choose the type of time do not know where to start. Today from the basic understanding to practical application, step by step to teach you to understand the design of flexible conveyor line points.

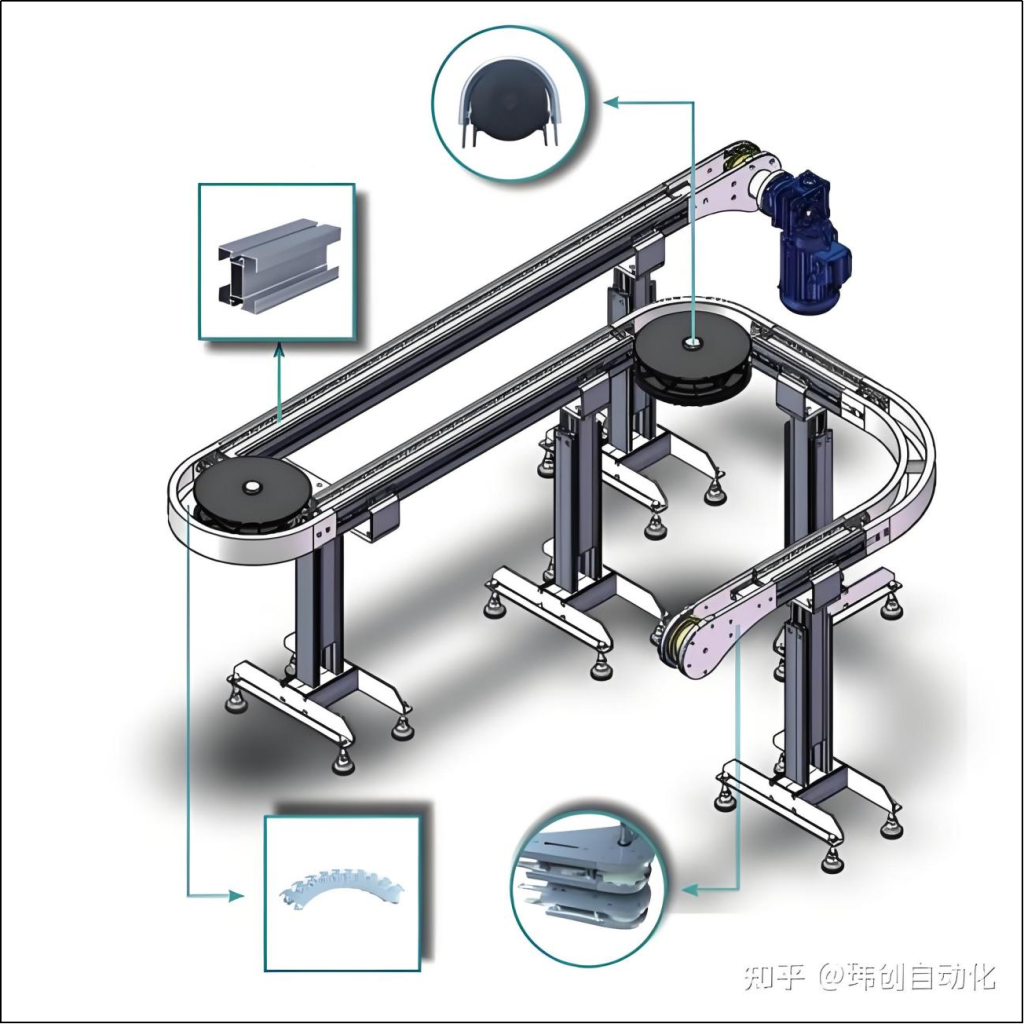

(Image source:Wei Chuang Automation)

One,Flexible Conveyor Linewhat it is

It is a three-dimensional conveyor that can be combined, mainly made of polyacetal (POM)Conveyor chain plateand aluminium alloy frame manufacturing. It is not as bulky as traditional conveying equipment, can flexibly cope with small turns and climbing slopes, and runs with low noise, which is very suitable for production lines with high hygiene requirements and insufficient space on the site. For example, it can be used with production in the new energy industry for conveying parts, pharmaceutical factories for transferring medicines, and the food and beverage industry for conveying packaged products.

Second, it is better than the traditional conveying equipment in what?

①Durable also(euphemism) go to the toilet::Traditional belt machine is easy to break, easy to be corroded, this conveyor line with POM chain plate, water and oil resistance is not easy to break, simple structure, usually do not have to maintain often.

②conveyancesmoothlyNo running away from it:The conveying surface is flat and smooth, driven by the chain wheel, the chain plate will not slip and run off, and the materials are transferred smoothly between different conveyors without worrying about spilling out or falling down.

(iii)Clean and compliant:POM chain plate is easy to clean up, can meet the new energy, food, medicine and these industries of health standards, do not have to be afraid of intermediate transport pollutants material.

④Layout flexibility:Equipped with horizontal and vertical turning conveyors, a single line can complete these actions of horizontal conveying, lifting and turning without having to repeatedly splice equipment.

III. Importantparametersnormpay close attention to

Flexible chain plate lineA variety of sizes are available.

The width of the conveyor beam and the width of the chain plate can be adapted to different products. It is easy to operate, and according to the production needs, it can also add the functions of convergence and divergence, and install electric, pneumatic or intelligent control devices to form a conveying programme suitable for your production line. No matter bottles, trays, cartons, cartons, PVC bags, all products can be conveyed stably.

IV. Where is it best used?

Highly clean production scenarios are very suitable for use. Like pharmaceutical manufacturing, cosmetics, food and beverage industry, using flexible chain plate line meets the hygiene requirements and will not contaminate the material. And it can be used in small sites. When the workshop space is not enough, its advantages of compact structure and flexible turning can make full use of the space. Highly automated production line is also suitable, such as new energy, bearing manufacturing industry automated production line, can be matched with intelligent devices to improve the conveying efficiency.

Selection of flexible conveyor line do not need to be difficult, remember these points above, according to their own production needs, pick the right and good equipment, so that the production line runs smoothly.