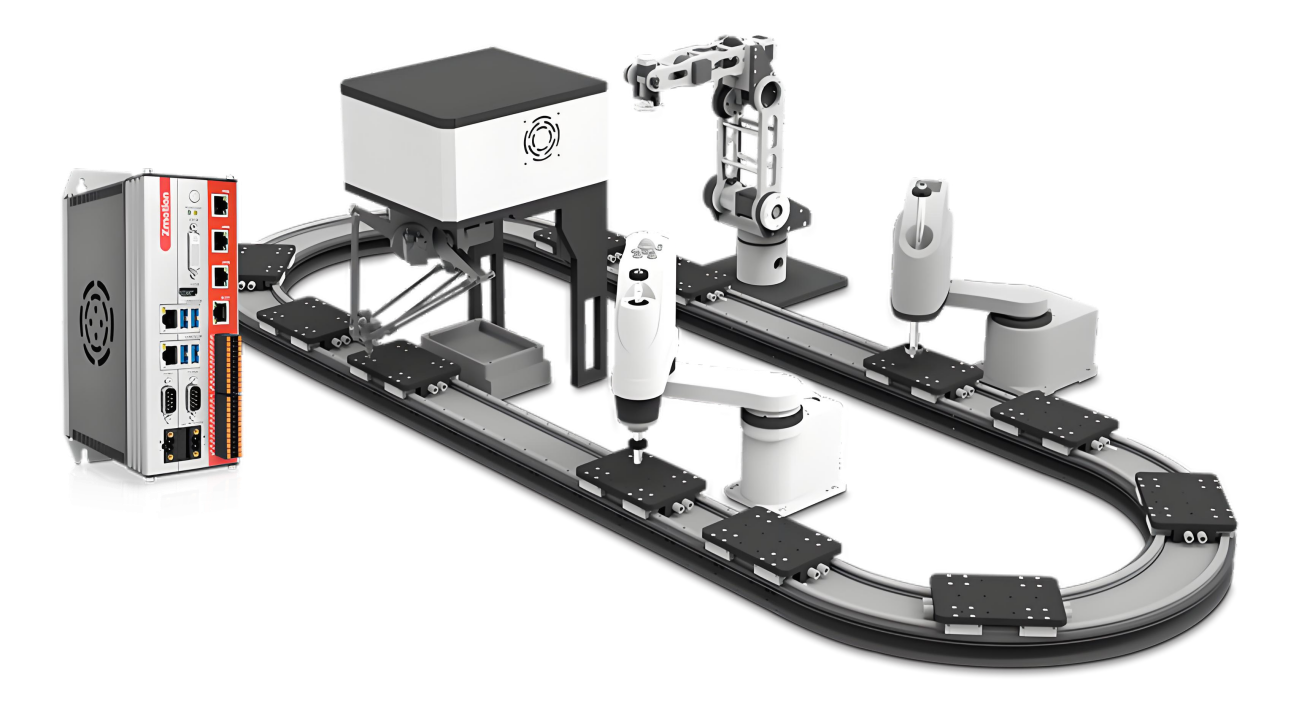

In the factory floor, you can often see a kind of equipment. A tray with parts or semi-finished products, along a fixed track automatically from one workstation to another, without the need for workers to carry, but also can be accurately parked in the place where it should be parked. This isWorkpiece pallet conveying lineIt is one of the core equipments to improve efficiency in modern factories, specialising in the automated flow of workpieces.

One,What exactly is a workpiece pallet conveyor?

Simply put, the workpiecePallet conveying lineIt is an equipment system that conveys workpieces (such as automotive parts, electronic components, battery modules, etc.) smoothly and accurately from one part of the production process to another, using the pallet as a handling container, through a mechanical structure and an automatic control system.

The whole process does not require manual handling, but also with processing, testing and other equipment automatically connected. For example, in the battery manufacturing plant, the battery module is placed on a pallet, which can be automatically passed from the assembly station to the testing station, and then to the drying area, the whole process is accurate and efficient.

Second, the four major pieces of the conveyor line: take apart to see its structure clearly

workpiecesPallet conveying lineLook complex, in fact, the core of the four parts, each has its own role, but also with each other.

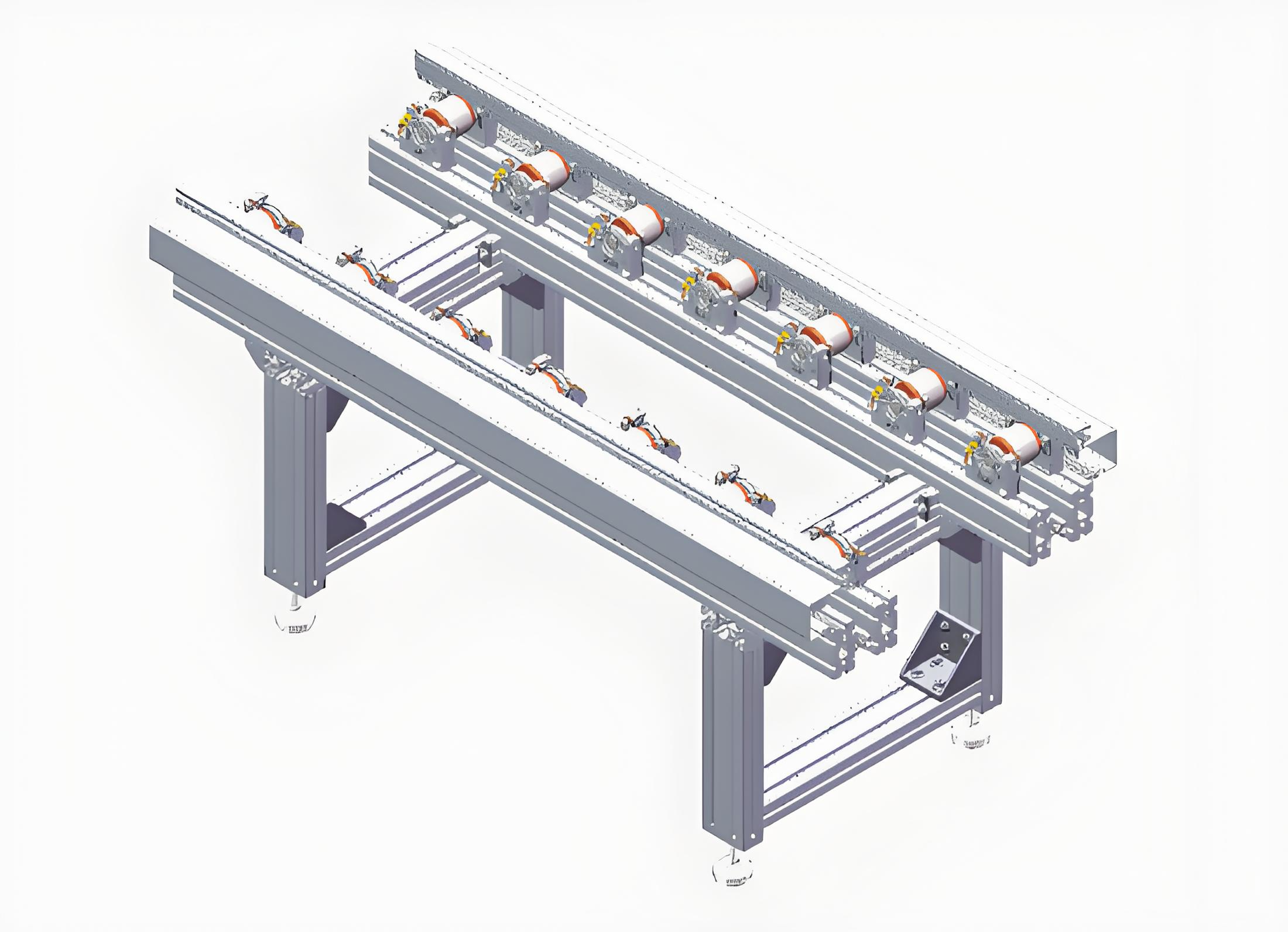

- Carrying and conveying units

There are three common types:

Roller type consists of a row of rotating rollers, suitable for heavier workpieces, such as automobile chassis parts, with strong load bearing capacity and smooth conveying. Speed chain type is driven by chain.palletsMobile, can achieve accurate start and stop, commonly used in electronic components, battery modules and other scenes that require precise positioning, a single pallet can even load 300 kg. Belt type is a flat structure like conveyor belt, suitable for light workpieces, such as mobile phone motherboards, home appliance parts, and will not scratch the surface of the workpiece when transferring.

2,Power & Drive Systems::

This part is responsible for powering the conveyor line, mainly the motor and reducer.

The motor is like the heart, driving the conveyor unit through a chain or belt. A speed reducer controls the speed and ensures that the pallets don't go too fast or too slow, for example, some lines can deliver 10 metres per minute, while others can accurately control it to a few centimetres per second.

3,Control unit:

It consists of PLC (Programmable Logic Controller), sensor and control panel. The sensor is equivalent to the eyes, can detect whether the pallet is in place, there is no workpiece, PLC is the brain, receiving the sensor signals to send instructions, such as to the machining position of the empty pallet to stop for 3 minutes to return to the flow, and even linkage of other equipment to automatically start the processing process.

4,Accessibility Module

It's a small accessory added on demand, but it doesn't do much.jacking and positioningCan automatically jack up the pallet and hold it in place after the pallet arrives at the work station, preventing it from shaking during processing. The lifting mechanism can make the pallet move up and down between the multi-layer conveyor lines to improve efficiency and save space. Turning mechanism can take the pallet to turn smoothly when encountering the corner of the workshop, without leaving separate space for straight path.

Three,The factory ishowHave to use it? The three cores.cutting edge

For factories, workpiece pallet conveyor lines are not a luxury but a necessity that can save costs and improve efficiency, with three main advantages.

1. Save labour and make fewer mistakes

A 40-metre-long motor assembly line, relying on the conveyor line to automatically transfer materials, can top the busy work of several porters. And manually moving goods are easy to fall, put the wrong workstation, pallet conveying line can be accurately positioned, the error is almost zero, especially suitable for electronics, medical and other industries that require high precision.

2. Space-saving and flexible

It can be customised according to the workshop layout. If the site is small, it can make a U-shaped layout, and if the floor height is high enough, it can add multi-layer lines and connect them with elevators, which is much higher than the site utilisation rate of traditional manual handling. And the modular design means that the later can be added to the length, change the route, such as production line expansion, directly add a section of the drum line on the line, without having to re-exchange equipment.

3. Reducing costs and improving efficiency

Pallets can be recycled and reused without frequent procurement of packaging materials. Conveying speed and beat can accurately match the rhythm of production, for example, the original manual handling of each station, etc. 2 minutes, now the conveyor line articulation is compact, can be shortened to 1 minute, a day down to the production of several hundred more products. In the long run, the investment in equipment can be quickly earned back by saving labour and increasing production.

Two,most commonly usedIndustry Scenarios

workpiecesPallet conveying lineHighly adaptable, it can move everything from light electronic components to heavy automotive parts, with a major concentration in the following industries:

- Automotive and Components ManufacturingIt will be used to convey heavy loads such as engine parts, chassis parts, etc., and is commonly used forplatenrespond in singingSpeed Chain LineIt can also be fully automated with touch welding and gluing equipment.

- New Energy IndustryIn the lithium battery factory, it can adapt to the high temperature and dustproof environment, and is responsible for the transport of electric core and module, and the combination of multi-layer wire body and elevator can improve the space utilisation rate.

- 3C Electronics IndustryUsing anti-static tray to convey chips and motherboards of mobile phones and computers, the belt-type conveying line can avoid damage to the components, and it can also be used with the testing equipment to achieve side delivery and inspection.

- Home Appliances and Household ChemicalsIn the assembly line of washing machine and air conditioner, it can convey shells, motors and other accessories, and the long-distance belt line can ensure smooth transmission and improve the overall assembly efficiency.

Three,When customising, pay attention to these key details

Factory fitted conveyor line can not just buy a set, have to be tailored to their needs, focus on these points:

1,Figure out the load bearing and dimensions first.

To know how heavy the pallet has to be to put the workpiece, for example, to move the battery module to bear 300kg, you have to choose theHeavy Duty Speed ChainIt is also important to know how big the workpiece is. It's also important to be clear about how big the workpiece is, the pallet size has to be just right to put it down, and you have to take into account the size limitations of the turn, the hoist, or the pallet could jam.

2,Plan the layout and speed.

To clarify the workshop starting point to the end of how far, to not turn, climbing, such as motor assembly line to do U-shaped layout more space-saving. It is also clear that the production beat requirements, such as 10 workpieces per minute to send, you have to calculate the conveyor speed, to avoid not keeping up with the rhythm.

3,Choose the right materials and accessories.

Wet rooms (such as food factories) have to be made of stainless steel to prevent rusting. High temperature areas (such as drying line) have to use temperature-resistant conveyor chain. If you need precise positioning, you have to add jacking positioner, these details directly affect the equipment life and use of the effect.

Overall, the workpiecePallet conveying lineLooking at the equipment for moving things, it is actually the central nerve that connects the whole production line. It uses automation to replace manual handling, and standardisation to solve the flow of chaos, so now more and more factories are inseparable from it.