In industrial production, synchronous belt and flat belt are two common transmission methods, each of them has a unique structure and application scenarios. Today, let us understand the differences between these two types of transmission belts, and how Wei Chuang's synchronous belt conveyor line and flat belt conveyor line can meet different production needs.

I. Main differences between synchronous belts and flat belts

1,framework

Timing belts have cog-shaped teeth, usually made of materials such as rubber or polyurethane, which mesh with the cog to achieve precise speed transmission.

Flat belts, on the other hand, have no teeth and consist of a flexible body, usually made of materials such as rubber, polyester or nylon, that relies on friction to transmit power.

2,transmission method

Synchronous belts are driven through the meshing of teeth and gears, enabling high-precision synchronous rotation, and are suitable for applications requiring high precision.

Flat belts, on the other hand, transmit power through friction and are suitable for scenarios that require greater transmission power and longer transmission distances.

3,Transmission accuracy

Synchronous belts provide highly accurate transmission of rotational speeds, maintain a stable rotation ratio and are suitable for precision positioning and mechanical movements.

Flat belts, on the other hand, are relatively simple to drive and are suitable for scenarios that do not require a high degree of precision.

4,load capacity

Synchronous belts are able to withstand larger loads due to the larger mesh area between the teeth and the gears.

Flat belts have a relatively low load capacity and are suitable for scenarios where large loads do not need to be carried.

5. Applicationstake

Synchronous belts are suitable for precision drives and for applications with high positioning requirements.

Flat belts are suitable for occasions that do not require high precision and require large transmission power.

Synchronous Belt Conveyor Line and Flat Belt Conveyor Line of Wei Chuang

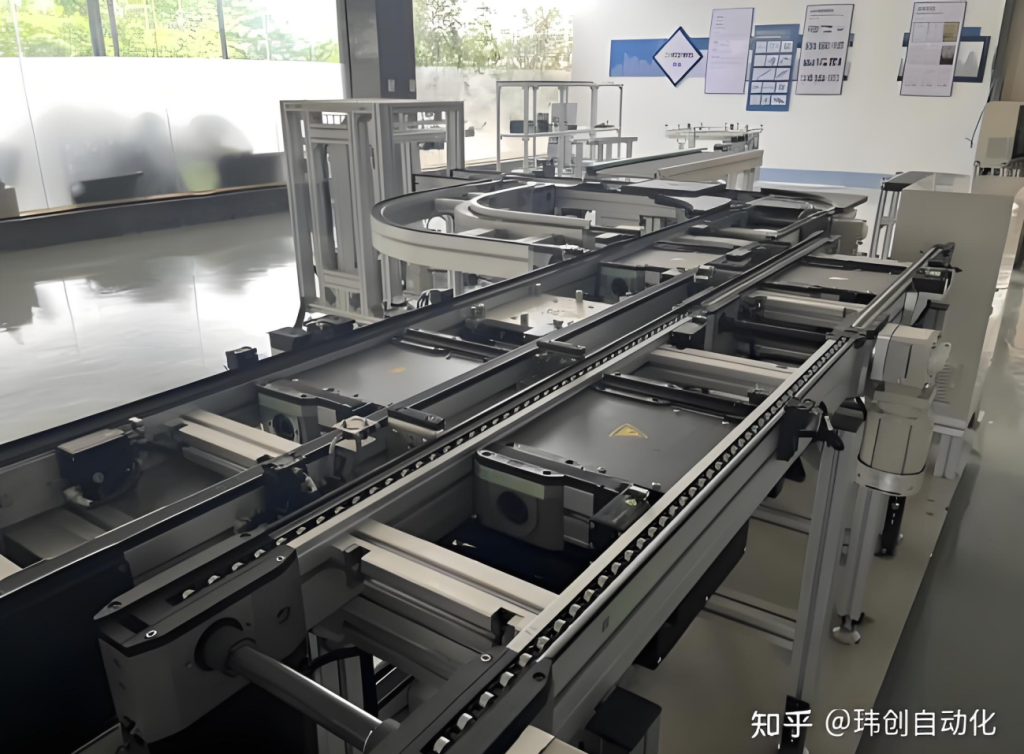

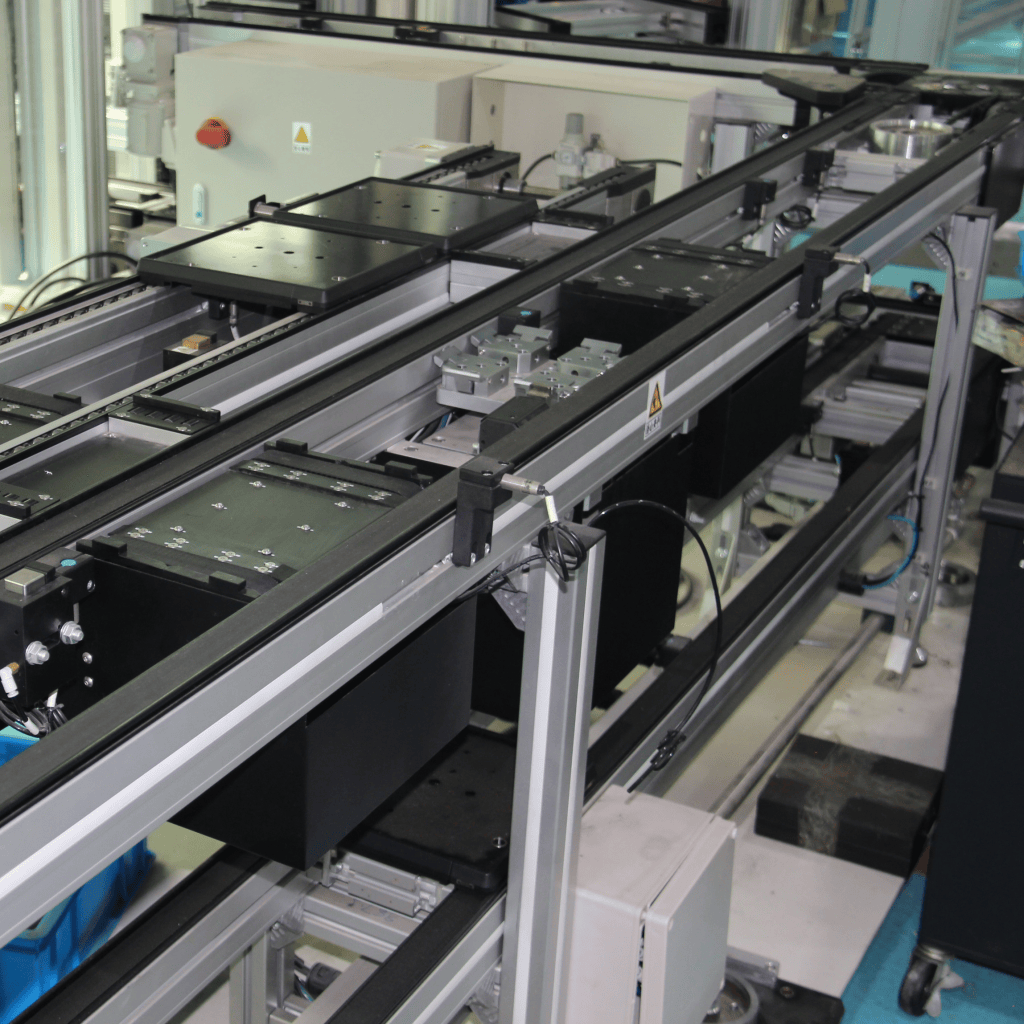

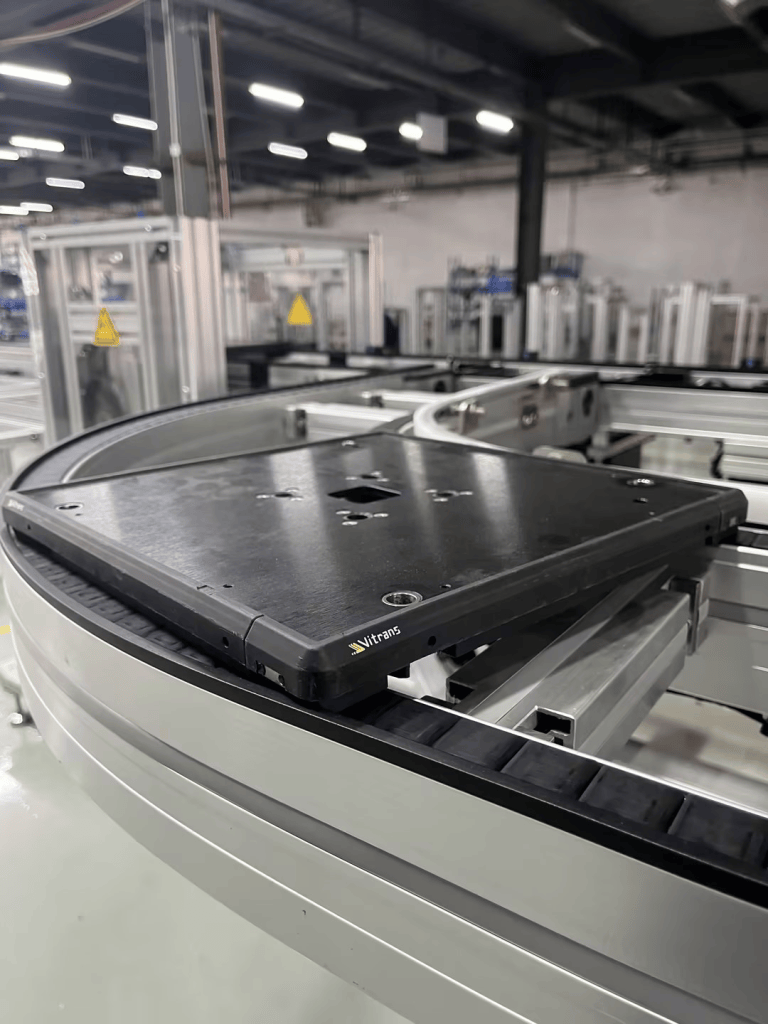

Synchronous belt conveyor line

Product Description:

The synchronous belt conveyor line of Wei Chuang adopts modular design with compact structure, which is easy to be used in combination with other automation modules to achieve flexible automation cycle conveying. Its conveying medium is toothed belt, the maximum load is 60kg, the longest length is up to 6 metres, and it supports positive and negative conveying.

Product Features:

With high precision and high wear resistance, it is suitable for conveying occasions with lighter loads and requiring high precision. The running speed can be adjusted in the range of 5~20m/min to meet the needs of different production speeds.

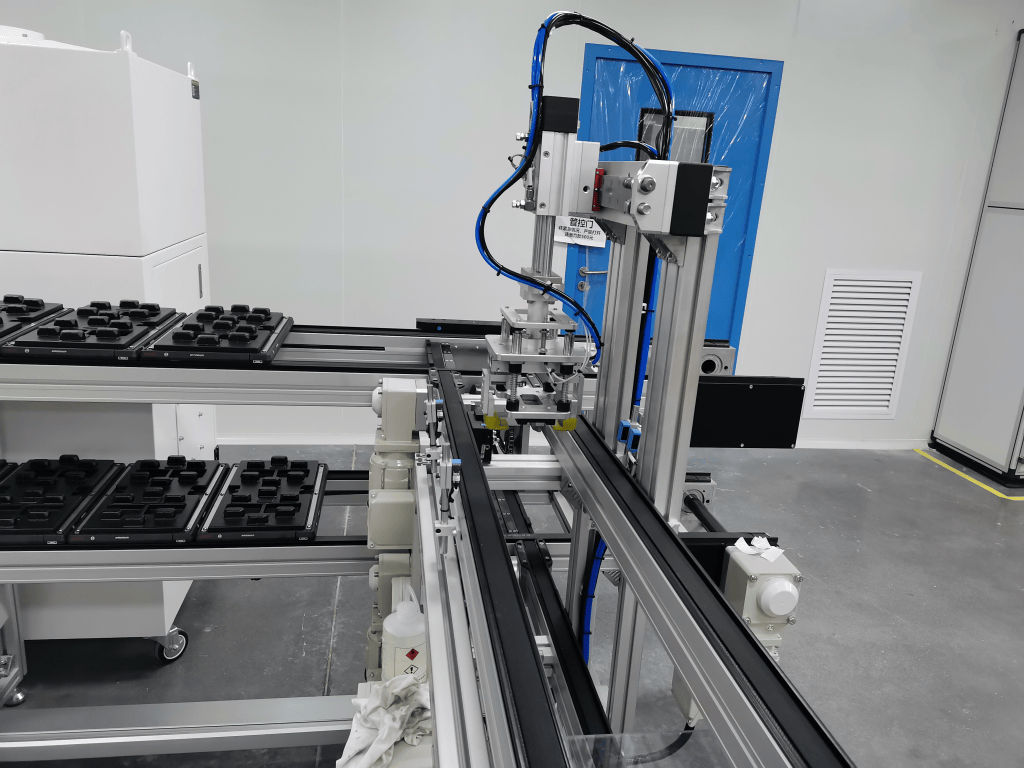

Flat Belt Conveyor Line

Product Description:

Wei Chuang's flat belt conveying line, the conveying medium is flat belt, the maximum load is 250kg, the maximum length is up to 25 metres, and only one-way conveying is allowed. With a wide range of conveyor line widths, it is suitable for production environments with high environmental requirements, complex material characteristics and the need for flexible layout and high automation.

Product Features:

The surface of the conveyor belt is flat and not easy to accumulate dust and material residues, which is conducive to maintaining cleanliness and suitable for industries with high requirements for cleanliness, such as electronic semiconductor, pharmaceutical, food, etc.

III. Recommendations for the selection of conveyor lines

The choice of which conveyor line to use should be based on specific application requirements and layout scenarios.

If your production scenario requires high-precision synchronised rotation and smaller loads, the timing belt conveyor line will be the ideal choice. It can provide stable and accurate speed transmission and is suitable for precision assembly and automated production lines. For scenarios that require greater transmission power and longer distance transmission, flat belt conveyor lines are more suitable. It can carry heavier loads and performs well in applications that do not require high precision.

Relying on the perfect combination of lean and flexible production model, Weichuang is able to meet the market demand for multiple models, large scale, small batch and individualisation. We not only provide a variety of automated conveying equipment and related conveying module products, but also provide automation upgrading solutions for production lines, to solve the most urgent and practical needs of customers. No matter which kind of conveyor line you choose, Wei Chuang will provide you with professional technical support and high quality after-sales service to ensure that your production process is smooth and efficient.