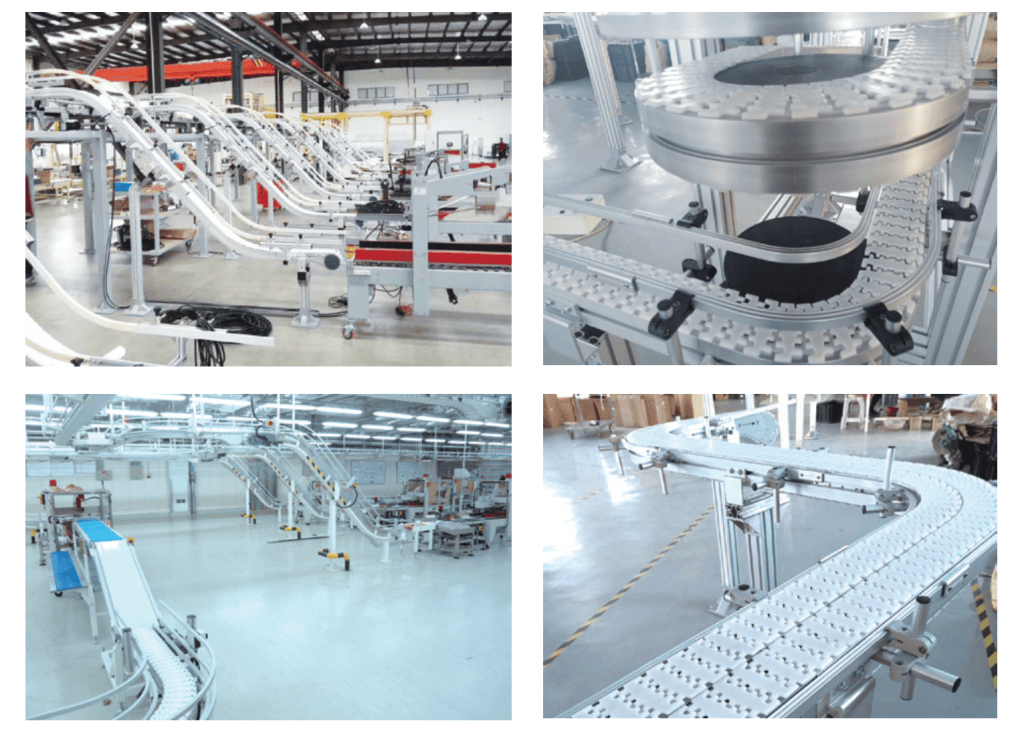

in the field of industrial automation.Flexible chain plate lineWith its flexibility, versatility, high efficiency and stability, it has become the core choice for many enterprises to optimise their production process. As a leading conveyor system manufacturer in China, Wei Chuang Automation has developed its own VF flexible chain conveyor system, which is supported by many customers for its modular design, high cleanliness standard and superb environmental adaptability.

Today, let's take a deeper look at the Flexible Chain Plate series of products to see what characteristics it has and how it can provide precise solutions to production challenges in different areas:

I. OnFlexible chain plate lineThe classification:

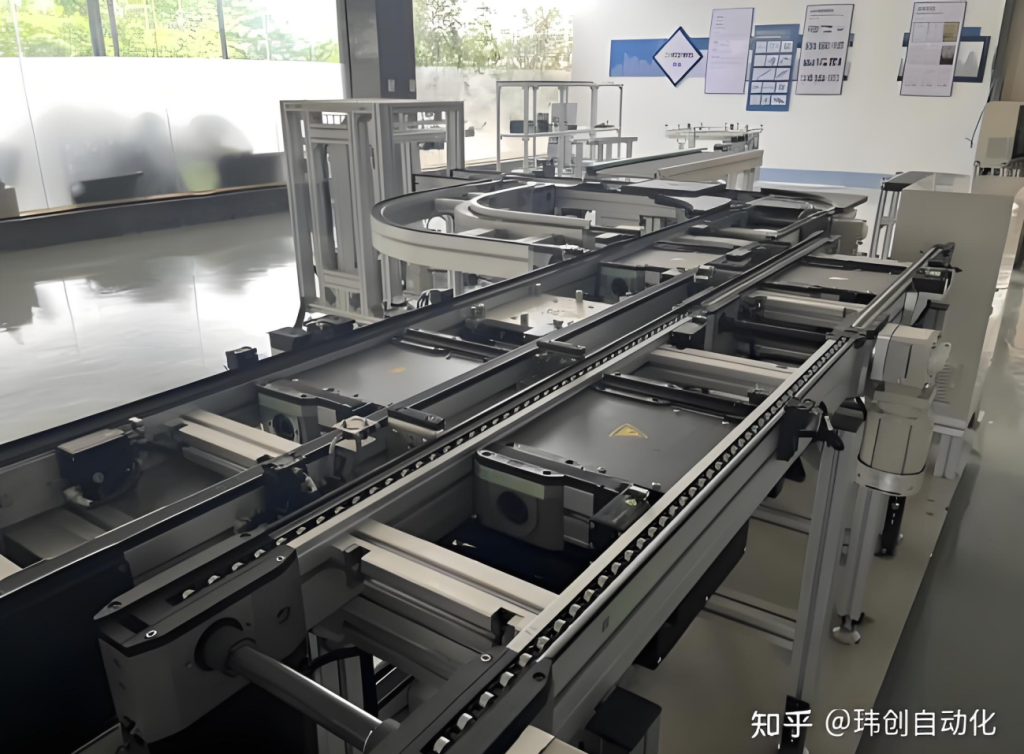

u Compact and lightweight–Flexible chain plate line

1. Core features

Lightweight structure: aluminium alloy frame + high-strength engineering plastic chain plate, the weight is reduced by 30%, which makes installation and handling more convenient.

-Modular design: supports quick splicing, flexible adjustment of length and width to adapt to changes in production line layout.

Clean and pollution-free: no lubricating oil is needed to avoid material contamination, in line with the cleanliness standards of pharmaceutical and cosmetic industries.

2. application scenario

-Pharmaceutical industry: clean conveying of vials and capsules

-Cosmetic workshop: mask, serum packaging line

-Small electronic components: sensors, microchip flows

2. Core strengths

✔ Save space and improve workshop utilisation

✔ Support push, support, hanging a variety of conveyor modes, a machine for multiple purposes

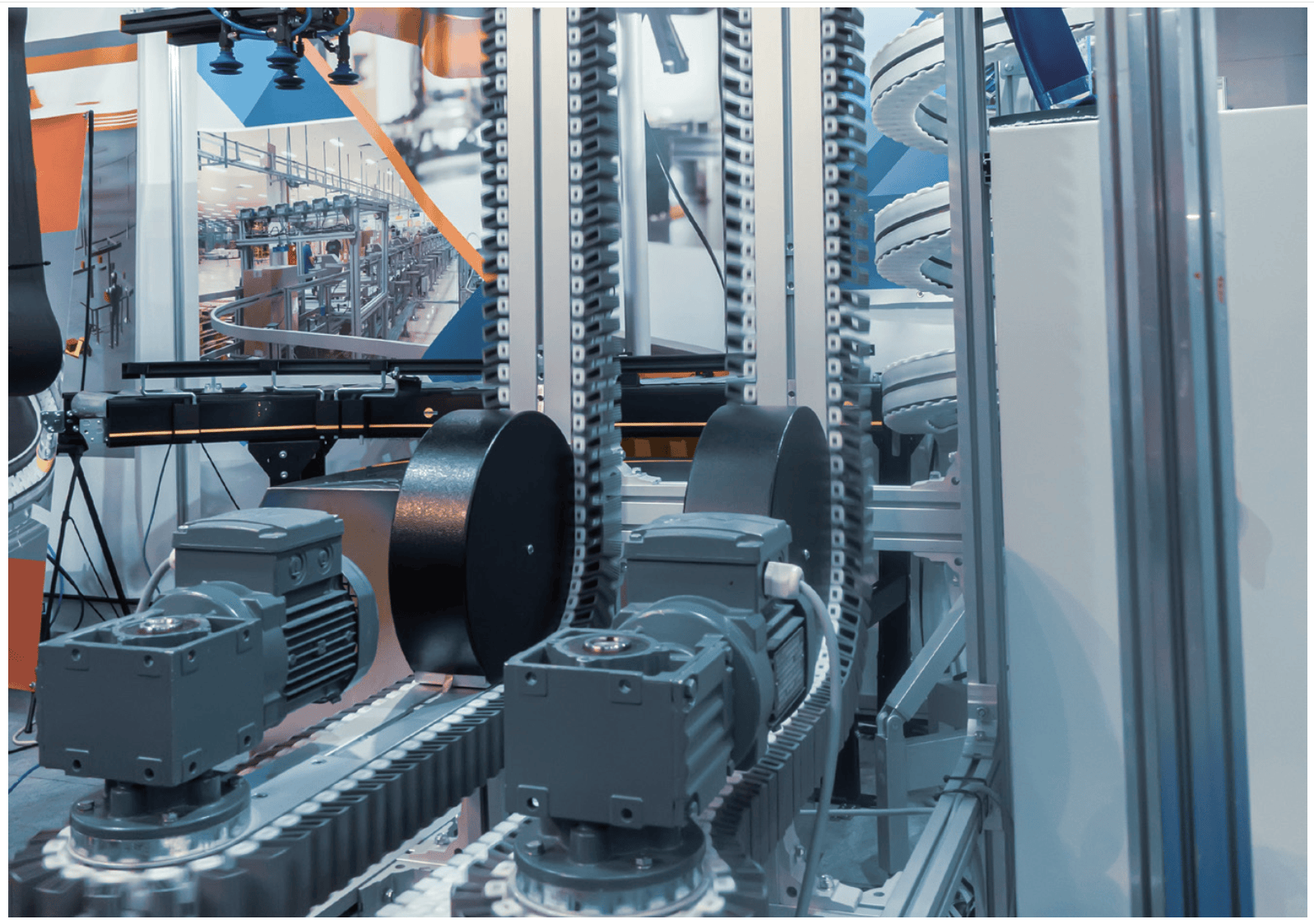

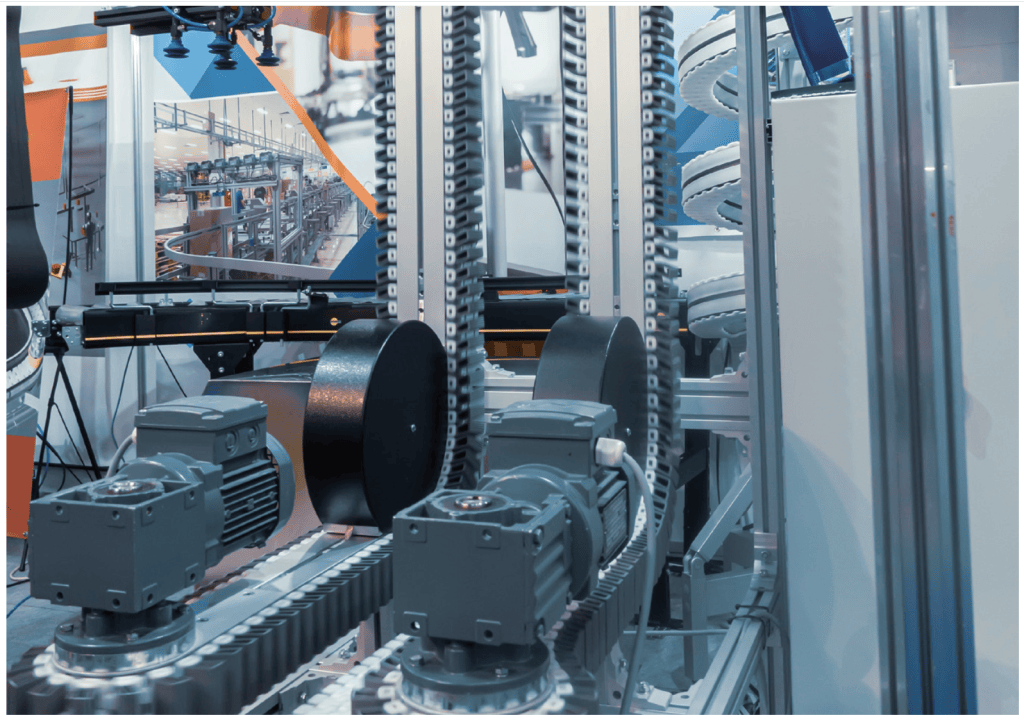

u High Duty Durable -Flexible chain plate line

1. Core features

Super load-bearing: thickened chain plate + double-layer roller structure, single-metre load-bearing up to 500kg.

Anti-corrosion design: surface plating treatment, acid and alkali resistance, anti-oil stains, adapt to the chemical and mechanical manufacturing environment

Low maintenance cost: self-lubricating bearings + wear-resistant chain plate, continuous operation life of more than 5 years.

3. application scenario

-Automotive manufacturing: assembly of heavy components such as engines and transmissions

-Home appliance industry: refrigerator, washing machine whole machine conveying

-Building materials factories: ceramic tiles, sheet metal handling

1. Core strengths

✔ 24 hours continuous operation without downtime

✔ Reduced manual handling and reduced risk of work-related injuries

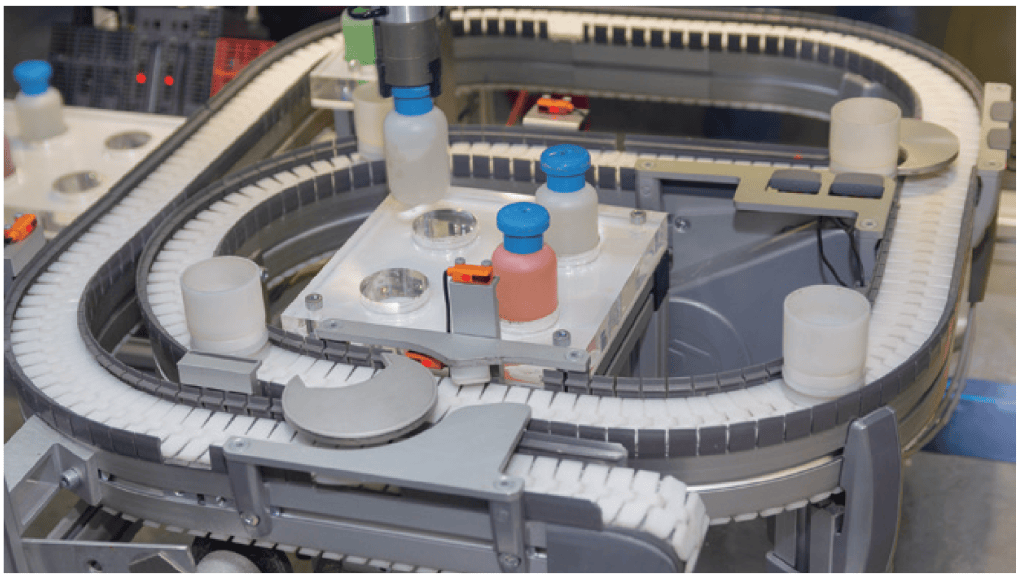

u Precision positioning typeFlexible chain plate line

1. Core features

-Accurate positioning: servo motor + photoelectric sensor, positioning error ≤ 0.5mm

-Flexible sorting: can be integrated with code scanning guns and robotic arms to achieve automatic sorting and assembly.

Intelligent interconnection: support MES/ERP system docking, real-time monitoring of production data

2. application scenario

-3C Electronics: Automated assembly of mobile phones and tablet PCs

-Photovoltaic industry: precise lamination of solar panels

-Precision instruments: optical lenses, chip package inspection

3. Core strengths

✔ Improve yield and reduce material loss

✔ Seamlessly connecting intelligent equipment to create a "black light factory".

II. SelectionFlexible chain plate lineTop 3 Reasons

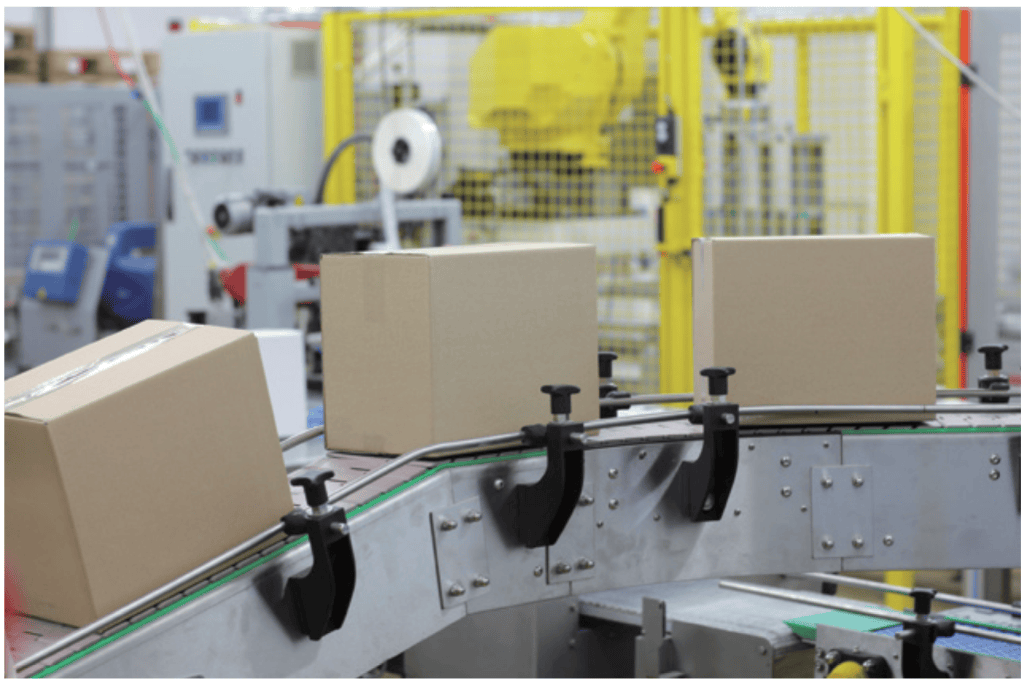

- Flexible adaptation: from light load to heavy load, from straight line to curved road, to meet the 90% and above conveying scenarios.

- Reducing costs and increasing efficiency: Reducing manual intervention and improving overall efficiency 40%-60%

- Long-term investment: modular design to support the later transformation and upgrading, equipment life cycle extension 50%

Three,concluding remarks

Whether it's the cleanliness needs of the pharmaceutical industry, the durability tests of heavy industry, or the exacting standards of precision manufacturing.Flexible chain plate lineAll can be cracked with customised solutions. When we choose the right chain plate series products, we should consider many aspects such as load capacity, speed, durability, customisation ability and after-sales service. Choosing the most suitable manufacturer and product according to our own needs, we can get the best solution.