As a necessary component in modern logistics transport, the efficiency and reliability of conveyor lines play an important role. The types of conveyor lines used in factory automation often vary depending on the purpose, so understanding the different types of conveyor lines is essential for us to streamline and optimise the production assembly process. Let's take a look at the types and uses of conveyor lines commonly used in factories, using products from Weichuang Automation as an example.

"one" radical in Chinese characters (Kangxi radical 1),belt conveyorthreads

Belt Conveyor LineBoth flat belts and timing belts are widely used in everyday industrial production.

1. Advantages:

①Easy maintenance, low transmission cost

Cost-effective for light-duty conveying (commonly 100kg or less).

③Applicable to higher cleanliness requirements.

2. Uses:

Ideal for transporting smaller, lighter components, electronics, and clean environments such as medical assemblies.

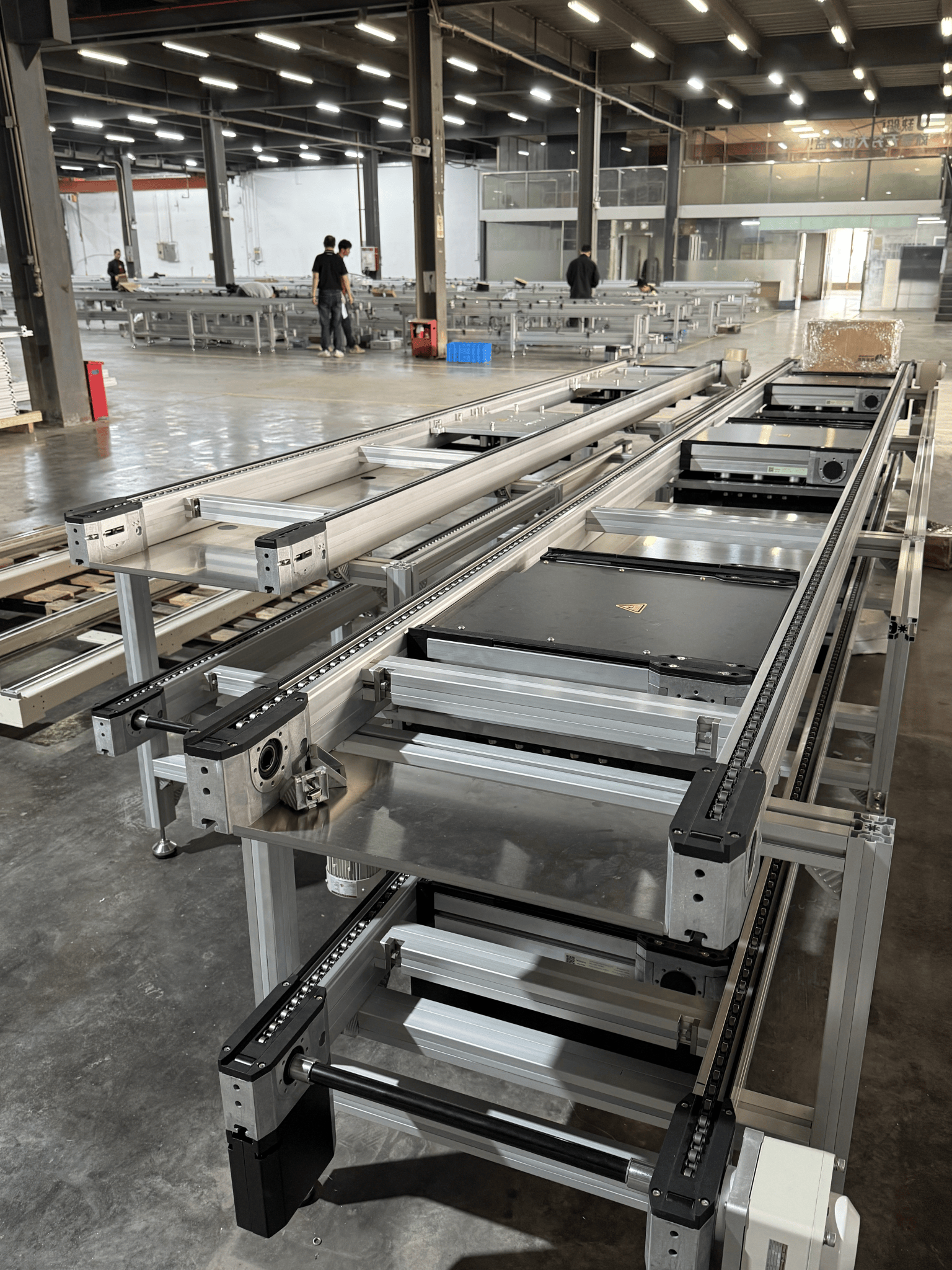

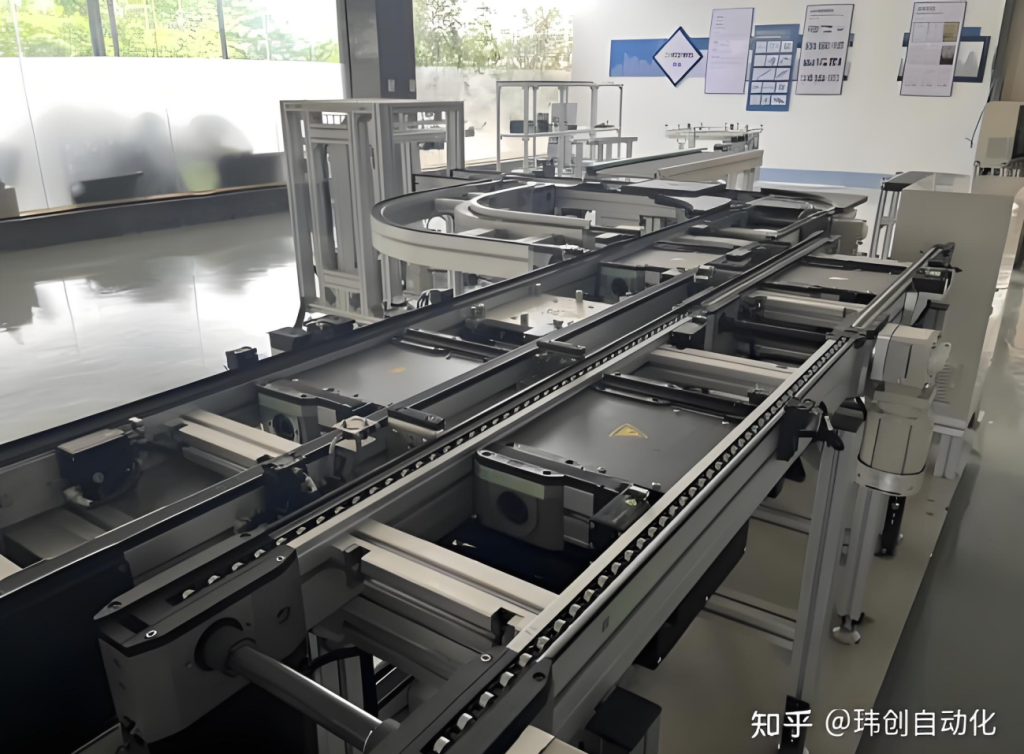

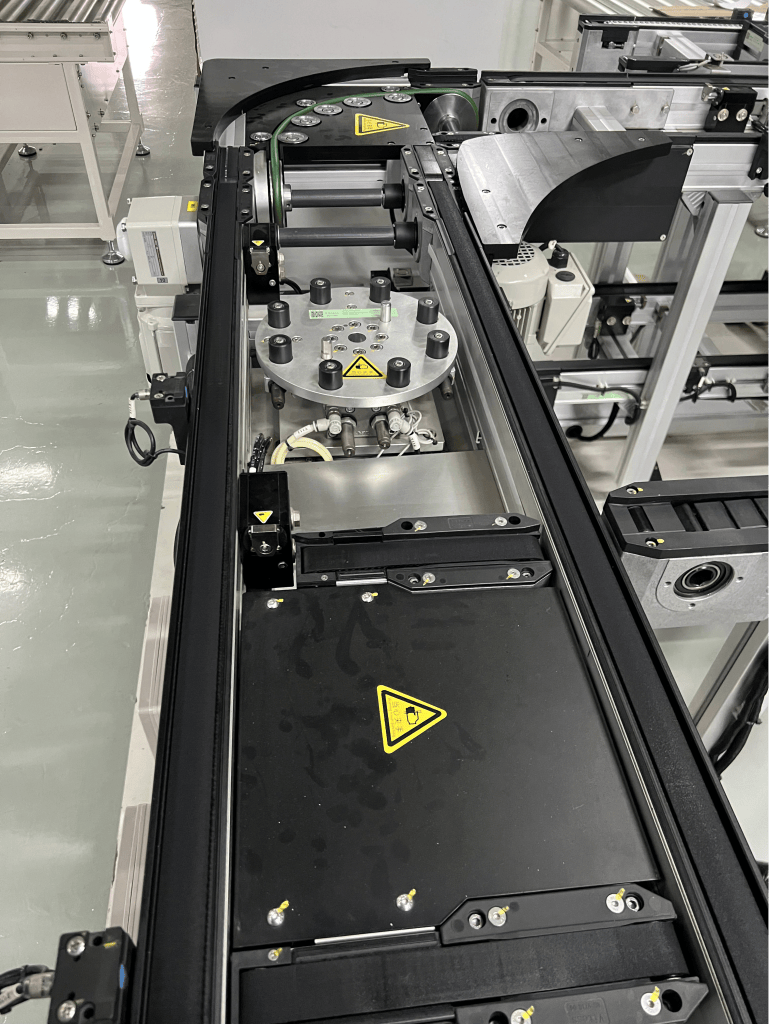

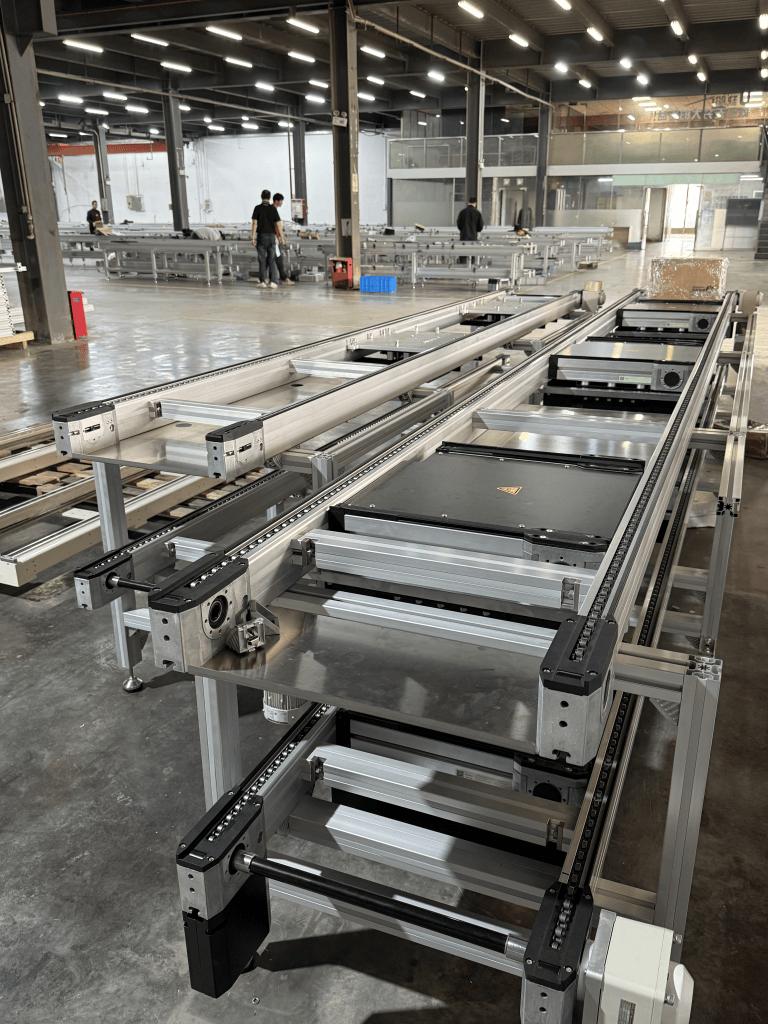

stupid (Beijing dialect),Roller Chain Conveyorthreads

roller chainA wide range of designs are available for the most complex applications.

1. Advantages:

Chain with rolling friction, more durable wire body

Roller chains can transport heavier loads

Mostly modular design, low cost

2. Uses:

Suitable for the production of electric vehicle batteries and material handling, as well as long-distance accumulation and conveying in factory logistics.

surname San,top chainconveyancethreads(Chain Conveyor)threads)

The efficiency of the conveyor mechanism is higher than that of the belt line, which is widely used in various industries.

1. Advantages:

① Stability and orientation

② Very durable and efficient

③Can handle heavier payloads than belt conveyor lines

2. Uses:

Overhead Chain Conveyor LineBetter suited to clean environments, including consumer goods, food handling, clean rooms, etc.

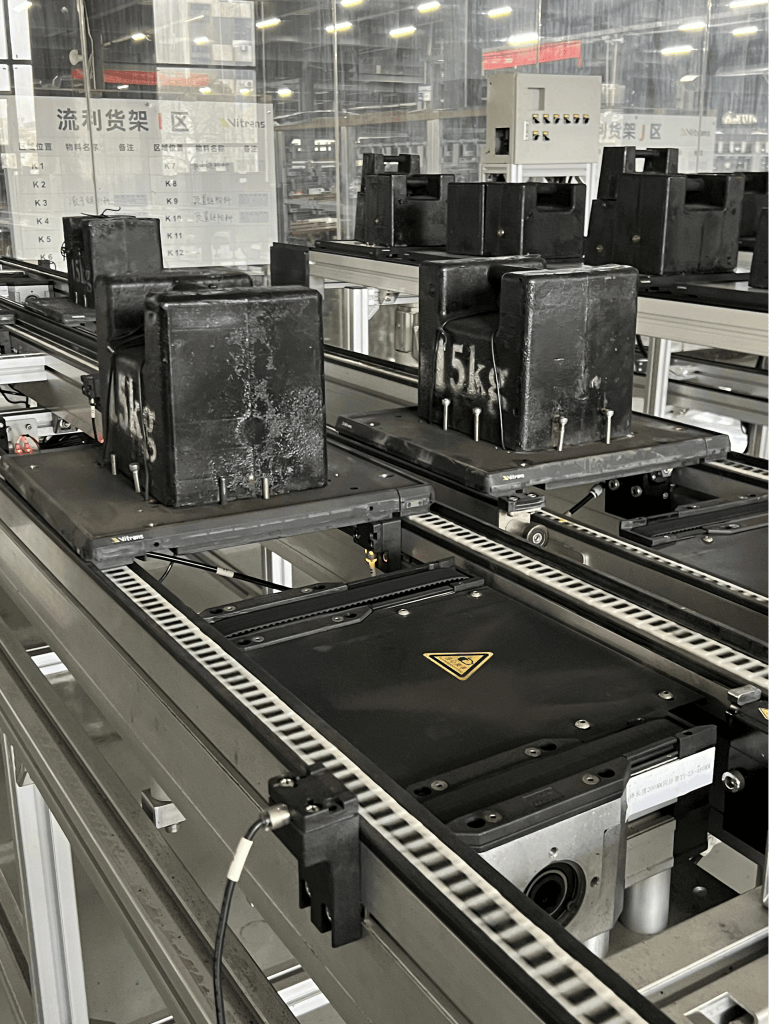

Four,roller conveyor

Typically have the highest payload capacity and offer the widest range of conveying solutions.

1,Advantage:

Reduction of manual labour stress

Massive increase in throughput

Quiet operation and low maintenance requirements

2. Uses:

Mainly used for warehousing materials, courier packing and conveying pallets and parcels, etc.

These 4 types of conveyor lines are all part of the boom in conveyor equipment and represent the epitome of progress in automated production. As the needs of end users continue to evolve, so do the forms of conveyor lines. Faster, more efficient, modular and flexible logistics conveying is becoming an important trend for the future.