Labour cost pressure, in the context of industrial upgrading, the choice of automation upgrade has become a must for many factories. So how to choose the assembly line in the unpredictable 3C field?

With deep industry insight, Weichuang Automation gives a clear answer: a flexible assembly line that is quick to realise, quick to adjust, quick to rebuild and quick to pay back is the smart choice!

I. Challenges facing the 3C industry

Assembly production in the 3C industry is a typical labour-intensive activity. At a time when labour costs continue to rise, enterprises are often caught in the "labour shortage" predicament. In order to break through this bottleneck, many factories have to seek automation upgrade road, but the level of automation equipment suppliers on the market are mixed, enterprises often face many risks in the selection process, a little careless may be in trouble.

II. Selectionflexible productionunderlying causes

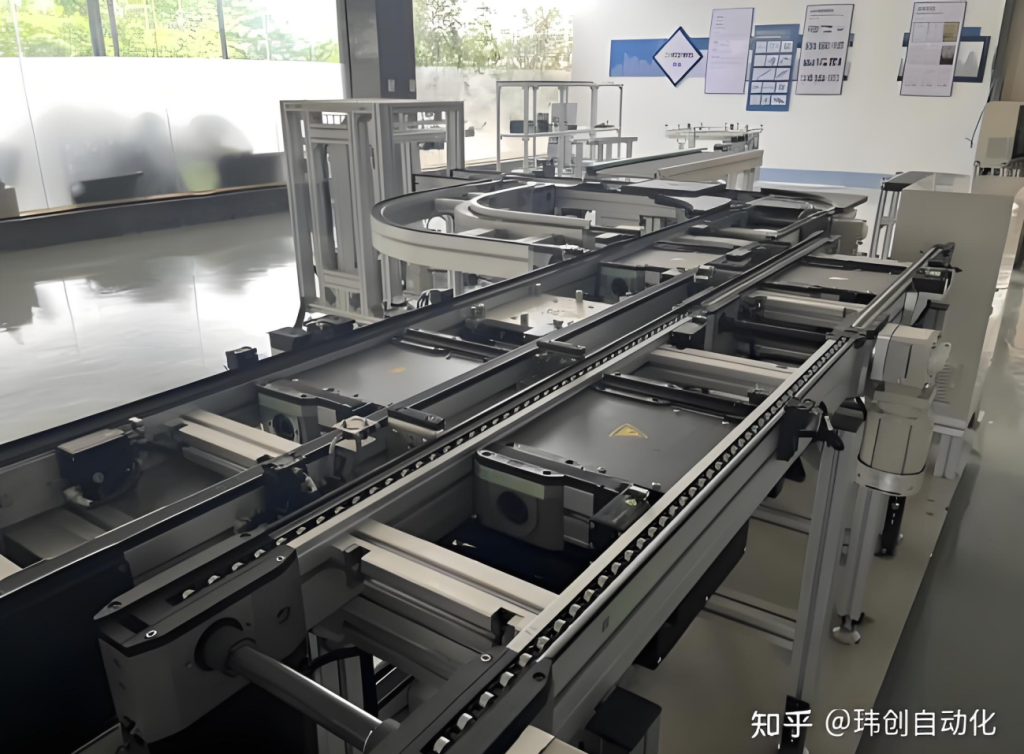

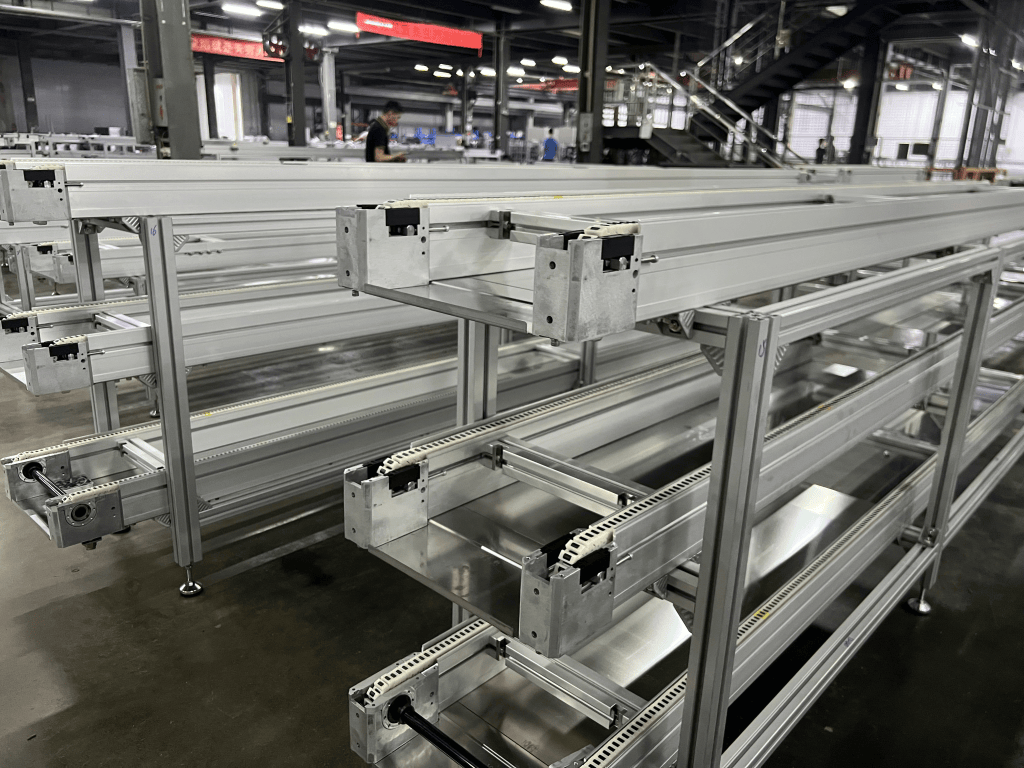

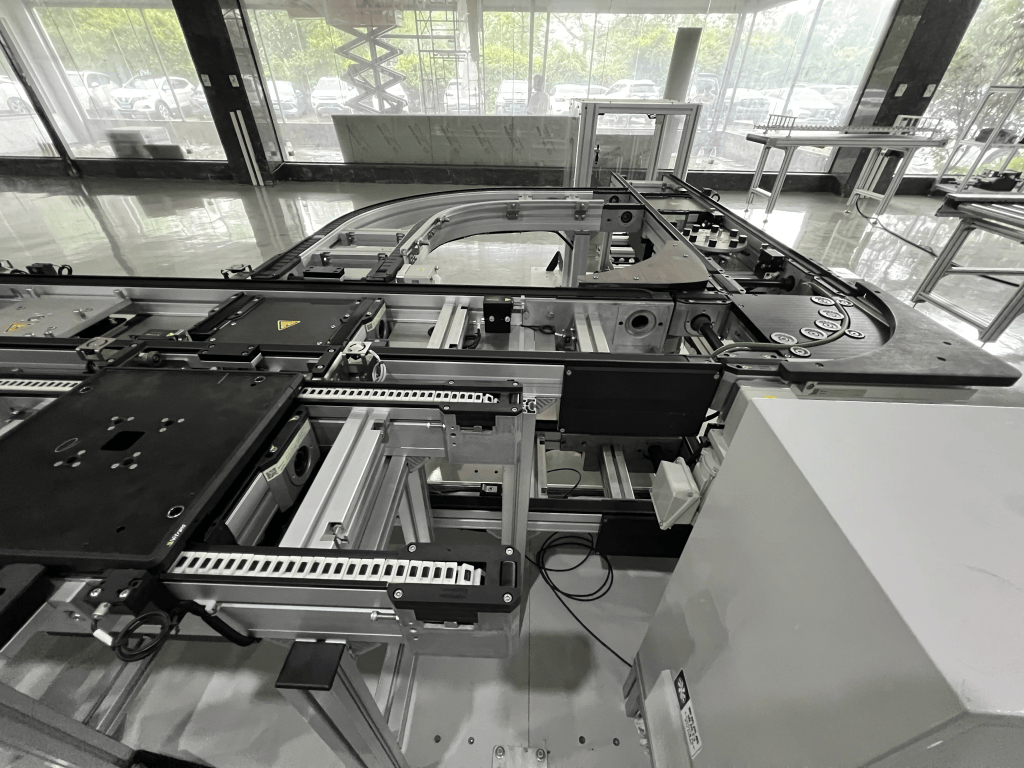

Compared with traditional conveyor lines, flexible assembly lines, with their modular design concept, can quickly realise the layout of the production line and put it into use quickly. Its flexibility is reflected in a number of levels: whether it is the rapid switching of similar products, or process changes in response to high efficiency, and even cross-product type of transformation, can be easily achieved, and transformation costs can be effectively controlled. The flexibility and efficiency of this line makes it ideal for automation upgrades in the 3C industry.

Wei Chuang's solution

Facing the diversified needs of automation upgrade in 3C industry, Weichuang Automation has launched a series of breakthrough solutions after dedicated research and development and practical verification:

- Flexible production line replaces the traditional conveyor line: in the production process, according to the product characteristics and process requirements, real-time adjustment of the addition or subtraction of processes, to provide a strong guarantee for the pre-project evaluation.

- Efficient reuse and low-cost modification: When replacing a machine type, only the relevant parts of the product need to be modified, so as to realise the replacement and modification of the accessory type and significantly reduce the modification cost.

- Modular design to reduce costs: the use of modular design of customised conveyor lines, later replacement or modification only need to target the key position, the other modules are flexible to adjust, compared with the complex automated line, the cost is lower.

Wei Chuang Automation is committed to making the automated production line:

-Automated production lines for even the largest assemblies can be handled with ease;

-Automated production lines that are even more challenging minimise risk;

-Products with large differentiation are able to allow production lines to be quickly switched or retrofitted.

Four,Why choose Wei Chuang?

Weichuang Automation provides customers with a comprehensive range of intelligent conveyor product types, coveringMultiplier chain line, belt line, roller line, chain plate line, ring guide, magnetic levitationetc., and provide customised solutions and exclusive services to meet the diverse needs of our customers.

From automotive manufacturing to 3C electronics, from electric motors to the shoe industry, Wei Chuang Automation has become the first choice of many enterprises with the following advantages:

-Wide range of products:We have a rich product line to ensure a certain stock reserve, and can quickly respond to customer demand.

-Competitive price and delivery time:With competitive price and fast delivery cycle, we help our customers to seize the first opportunity in the market.

-Ten years of industry experience:With a decade of experience, we provide precise and customised solutions to our customers.

-Excellent quality and service:We have established long-term relationships with many well-known manufacturers, and our quality and service are widely recognised.