I. Dystopian reality: "labour shortage" in the context of the crisis of fault lines

"You can't recruit a mechanical designer for $180,000 a year!" An automotive group recruiter exclaimed. China Mechanical Engineering Society data show that the shortage of mechanical engineers has reached one million people, but the mechanical graduates of colleges and universities, the rate of change of profession is as high as 58%, the rate of turnover within 3 years of employment is more than 45%. on the one hand, companies are crazy to carry out the war for talent, on the other hand, it is the young people to avoid it. This absurd "labour shortage", uncovered the most painful scars in the transformation and upgrading of China's manufacturing industry.

Second, the five pain points: unveiling the survival of mechanical engineers predicament

1. The "workshop gap" between ideals and reality

"CAD drawings are drawn until the early morning, and rework in the workshop is done until the legs are weak" - 29-year-old Wang Gong said the double pressure of mechanical designers. 85%'s mechanical engineers need to go down to the workshop frequently to follow up the production, and switch between computer graphics and on-site debugging repeatedly, the work intensity is far more than that of ordinary white-collar workers. The intensity of work is far more than ordinary white-collar workers. A recruitment platform research shows that the average weekly overtime hours of mechanical engineers 14.6 hours, far more than the IT industry (9.8 hours).

2. The salary illusion: the averaged "10,000 yuan per month"

Behind the surface of the high salary there is a serious geographical division: the Yangtze River Delta mechanical engineers average monthly salary of 12,000 yuan, the central and western regions only 6500-8000 yuan. More serious is that after 35 years of age, salary growth stagnation phenomenon is common, a forum research shows that 42% senior engineer salary stuck in 200,000 annual salary threshold is difficult to break through.

3. The "instrumentalist" dilemma of the lack of a sense of professional value

In the R & D system, mechanical engineers are often regarded as "drawing tools" rather than the main body of innovation. An aerospace company employee said frankly: "the structural design is the last to speak when the programme is discussed, but it is the first to bear the brunt of the problems." This situation of "high responsibility and low voice" has led to a continued low sense of professional identity.

4. The "life and death" of technology iteration

From traditional mechanical design to mechatronics, from 2D drawing to 3D simulation, the technology iteration cycle has been shortened to 2-3 years. 38-year-old Zhang Gaogong said, "Last year just proficient in ANSYS, this year we have to learn digital twins, slow transformation will be eliminated." This continuous technological anxiety accelerates the brain drain.

5. The "generational gap" of the school-enterprise disconnect

A 211 college mechanical college professor helplessly admitted: "laboratory machine tool models than the factory 15 years behind, students have not even seen a modern CNC system." Enterprise surveys show that 63% new entry mechanical engineers need more than six months to adapt to the period, the cost of talent training has been high.

III. The way out: rebuilding a system of dignity for technical personnel

When German mechanical engineers enjoy the same social status as doctors, when Japan's "craftsmanship" has produced world-class manufacturing masters, China's manufacturing industry must answer three core propositions: how to break the prejudice of "sitting in the office is more noble than in the workshop"? How to build a clear career promotion dual-channel? How to achieve a real deep integration of industry, academia and research?

Some areas have already been explored:

- A heavy industry enterprises to implement the "sequence of technical experts", the top mechanical designers can enjoy vice president-level treatment.

- Shenzhen Institute of Vocational Technology and DJI co-operate to open "Intelligent Manufacturing Special Class", realising seamless connection between courses and jobs.

- These practices reveal that only by breaking the traditional structure of "management over technology" can the attractiveness of the mechanical engineer's career be rebuilt.

IV. Future challenges: reshaping roles in the era of smart manufacturing

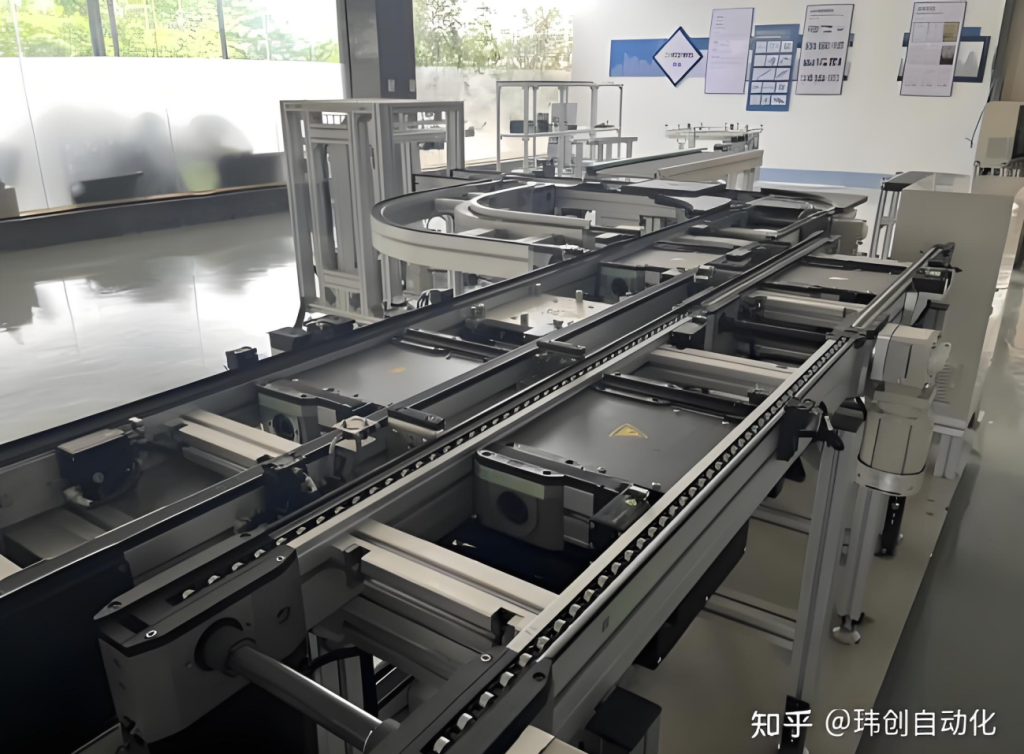

According to the "Made in China 2025" plan, by 2030, the demand for high-end equipment talent will exceed 3 million. Under the wave of Industry 4.0, mechanical engineers are no longer simple "draftsman", but the integration of mechanical, electronic, algorithmic composite talents.

And according to McKinsey forecast, by 2025 China's industrial automation market size will exceed 400 billion yuan. In this industrial upgrading battle for the country's fortunes, when more and more young people flee the industry, we lose not only a number of technical positions, but also the core competitiveness to support the upgrading of the manufacturing industry. The next decade, is to continue to use "young people can not suffer" accusations to avoid systematic reform, or to build a true respect for the value of technology ecosystem? This is a question of choice, about the survival of China's manufacturing.