I. Differential speed increase: a code for efficiency in mechanical design

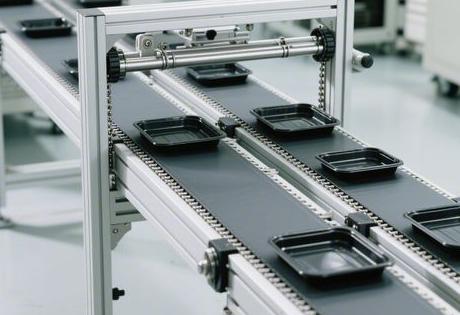

At the heart of the ring multiplier chain liesDifferential design of roller and roller diameters(Usually D/d=2.5~3), through the principle of motion superposition to achieve the unique effect of "low-speed chain, high-speed conveying":

- Velocity stacking formula: Tooling plate speed Vgather

= Vcable length (= 1

× (1 + D/d), when the roller diameter is twice the roller, the conveying speed can be up to 3 times the chain speed. - Double reduction in consumptionChains run at low speeds to reduce 30% wear, engineered plastic rollers reduce noise to below 65dB and extend life to 50,000 hours.

- precision accumulation and releaseThe workpiece plate can achieve ±0.15mm precision positioning by pneumatic stopper, and support any workstation pause and release.

Chengdu Fujitsu production line test shows: the use of 3 times the speed of the chain, laptop computer assembly beat from 120 seconds compressed to 75 seconds, the efficiency of 37.5%. this mechanical ingenuity, is precisely theChengdu manufacturing industry to crack the "efficiency-energy consumption-precision" triangle of the key fulcrum of the problem.

II. Ring closure: the industrial magic of spatial reconfiguration

The ring design creates new value through space folding compared to conventional linear doubling chains:

- three-dimensional road line: Upper carrier plate conveys workpieces, lower empty plate returns automatically, eliminating ineffective handling of the 30%.

- Corner Revolution: Pneumatic lifting device integrated at 90° turn, the time taken to turn over the carrier plate is <2 seconds, avoiding the risk of manual intervention.

- Modular extensionsSupporting horizontal/15°climbing/double-decker layout, achieving 40% capacity increase per unit area in Longquanyi Automobile Industrial Park.

case-based evidenceAn aerospace parts factory in Chengdu transformed its 80m straight line into a 45m circular layout, increasing plant utilisation from 65% to 89%, and increasing daily production capacity by 18%. this design is a perfect match forHigh Density Production Requirements in Chengdu Industrial Park-- Against the backdrop of a 12% average annual rise in land costs, space is profit.

III. Chengdu Practice: Empowerment Mapping of Three Industries

1.Automotive Manufacturing Cluster

- FAW-Volkswagen Chengdu Base: Ring chain carries 1.2 tonnes of engine blocks and works with collaborative robots to achieve a 4-minute/unit assembly beat.

- New Energy Battery Pack Conveyor: Carbon Steel Rollers with Anti-Deformation Design, 2.2 Times Increase in Speed Ratio under 2 Tons Load

2.Electronic Information Corridor

- BOE LCD panel line: anti-static work board + ±0.1mm positioning accuracy, to ensure that micron-sized components are transported without damage.

- Foxconn SMT Workshop: Sliding Contact Line Integration Technology Enables Powered Detection, Improves Fault Response Speed by 90%

3.New Economic Scenario Breakthrough

- Shuangliu Cold Chain Logistics Park: Stainless steel chain operates stably in -25℃ environment, energy consumption is reduced by 35% compared with roller line.

- PI Prefabricated Sichuan vegetable factory: IP54 protection motor against hot and humid steam, cleaning cycle shortened 50%

IV. Smart Evolution: A Triple Leap Driven by the Internet of Things

The Chengdu Industrial Plan 2025 shows that the multiplier chain system is undergoing essential changes:

- Perceptual Layer ImplantationEmbedded RFID chips in workpiece boards, real-time uploading of position data to the MES system, and compression of changeover time to 1/6 of the original process.

- reconfiguration of energy sources: Popularity of permanent magnet synchronous motors, energy consumption reduced by 40% compared to conventional asynchronous motors (measured data 8.2kW → 4.9kW)

- human-machine collaboration: Force Sensing Stopper Response Threshold 5N, Crash Rate Reduction 90%

Data from 12 demonstration factories in Chengdu Economic Development Zone confirm.Intelligent multiplier chain system shifts break-even point down for small orders 37%, providing the underlying support for multi-variety flexible production.

Exclusive insight: the underestimated "ability to monetise space"

Chengdu's practice reveals the deep value of the ring doubler chain beyond the conveying tool:

- spatial arbitrage model

The saved plant area is transformed into new production lines, and the annual income from the improvement of ping efficiency is ≈ 23% of the equipment cost (the average value of enterprises in the Economic Development Zone). - Skill dependency decoupling

Accumulation function enables unskilled workers to work in 3 days, reducing labour costs and maintaining yield 99.2%+. - Capacity option effect

Fast response to order fluctuations through variable frequency speed control (2-20 m/min), 30% capacity adjustment can be completed within 48 hours

This property makes itThe optimal first move for intelligent transformation of manufacturing companies in the Midwest--60% less investment than a fully automated production line, but 85% performance improvement.

Self-questioning: Four questions about the core of Chengdu's circular doubling chain

Q1: How does the circular design solve the problem of high land costs in Chengdu?

A: Closed-loop layoutSaving 30%-50% Occupied areaIn the context of the annual average land price increase of 12% in Chengdu Industrial Park, it is equivalent to creating an additional revenue of 7.2% per year.

Q2: Does heavy transport sacrifice multiplier performance?

A: Dual sprocket differential structure + carbon steel roller scheme, even if loaded with 2 tons of automotive moulds, still maintain 2.2 times the speed increase, roller deformation <0.1mm.

Q3: How to avoid the loss of transferring machine by changing production frequently?

A: Chengdu Manufacturer R&DMagnetic quick-change systemStandardised fixture interface + pneumatic locking mechanism, changeover time compressed from 45 minutes to 6 minutes.

Q4: How to prevent rust in rainy and humid environment?

A: Adoption316L stainless steel chain + nano coatingKey bearings are injected with composite grease and tested by salt spray for 4800 hours without corrosion.When the ring doubling chain flows around the clock in Longquanyi's workshop, it conveys not only parts, but also a kind ofA philosophy of reconfiguration of space and time--Creating infinite production possibilities within finite physical constraints.