In the production process of lithium battery cells, a variety of conveyor systems play their respective roles to ensure efficient and orderly production. Today we will take you to know the five core transport systems in the production of battery cells!

○Air Logistics Conveyor System

l principalEquipment.

Intelligent Dispatch System + Roller Line + Elevator + Lift Transplanter + Rotary Table + Specialised Pallets

l Core mandate.

Key auxiliary materials, such as isolation film, top cover and aluminium shell, are accurately fed into the clean production area through elevated rails and automatically docked to the equipment to complete the loading.

l Workflow.

Workers unpack and place material pallets → elevated main line conveys to each branch line → elevator smoothly descends to the ground level → docking equipment or manual workstation. Empty pallets are returned to the starting point, forming an efficient closed loop.

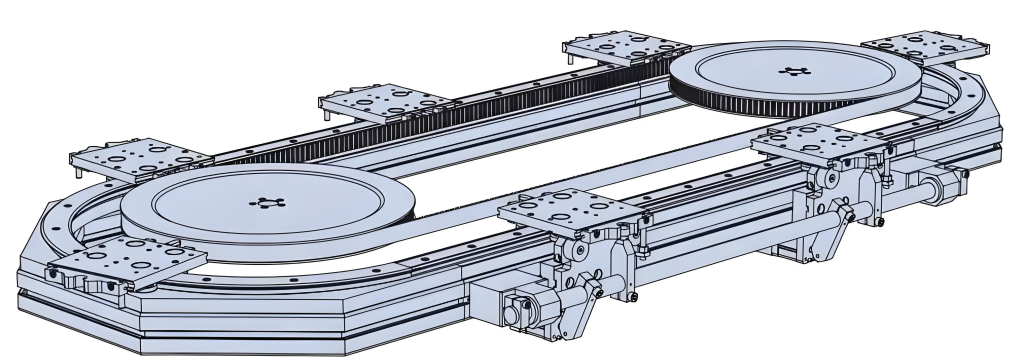

○Central Logistics Conveyor System

l principalEquipment.

Intelligent Dispatch System + Double Deck Logistics Line + Circular Lift + Pallet Escape Door + Lift & Translator + Core Ferry System

l Core mandate.

Efficiently connecting each production equipment to achieve automated flow of battery cores, docking of loading and unloading materials, and intelligent caching between processes.

l Workflow.

The scheduling system is linked with the equipment in real time → accurately coordinates the movements of the logistics line, lifts and other institutions → ensures that the electric cores flow as needed and the production rhythm is seamlessly matched.

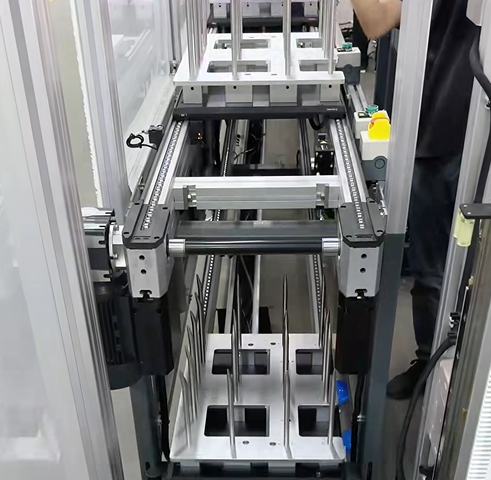

○Pallet conveyor system with caching function

l principalEquipment.

Multi-level main/support conveyor (with empty pallet level, full pallet level and double caching level) + inter-level lifts + positioning mechanism + unloader + loading mechanism

l Core mandate.

Classifying and conveying all kinds of battery cores to the assembly section, the four-layer three-dimensional structure realises the dynamic caching of empty/full pallets, which can effectively deal with the unexpected downtime and guarantee the continuous production.

l Workflow.

Empty pallets are lifted from the bottom of the branch line to the full pallet level → positioned and loaded with cores → full pallets are transferred to the main line → conveyed to the assembly section for loading. Multi-layer caching for flexible response to flow fluctuations.

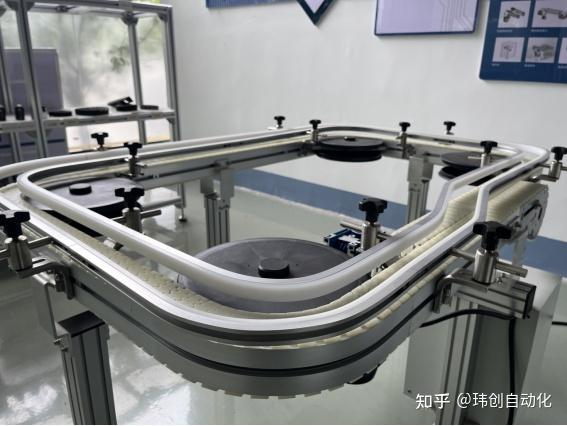

○Maglev-based conveyor system

l principalEquipment.

Maglev Rail + Smart Cell Carrier (with Liftable Mount)

l Core mandate.

The carrier adsorbs the core along the magnetic track and moves it precisely to the working station, and then adjusts the height by lifting and lowering for direct processing, eliminating the need for repeated pick-and-place steps.

l Workflow.

The core is fixed to the carrier → Maglev drives it to the target station → the carrier lifts the core close to the machine → the processing is completed and it goes to the next station.

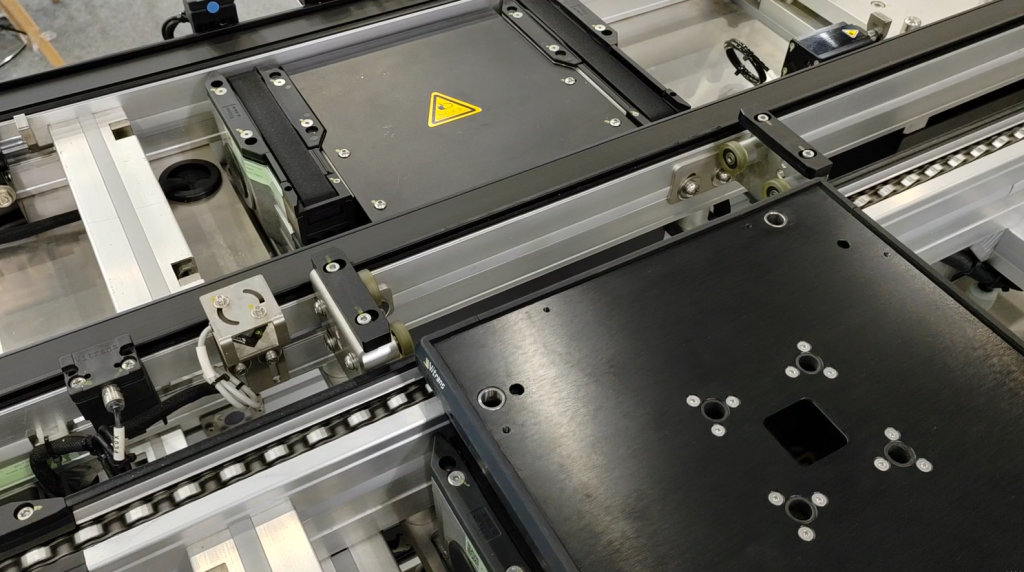

○Belt conveyor system with positioning function

l principalEquipment.

Conveyor Belt + Fascia Plate + Alignment Plate + Bi-directional Alignment Blocks + Dual Drive Mechanisms

l Core mandate.

High-precision positioning of the electric core during the conveying process lays the foundation for subsequent automated transfer.

l Workflow.

The core is transported between the two alignment plates → the first alignment block pushes the core against one side → the second alignment block pushes the core against the stopper → 2D precise positioning is completed.

These intelligent conveying systems play an indispensable role in the production of lithium battery cells, they not only improve the production efficiency, but also to ensure the stability and continuity of the production process.