If you are preparing for automation from this year, then your factory will certainly need it - the efficientPallet conveying systems. The same is a conveyor line, why is the difference so big? Pallet conveying line compared to the traditional belt line advantages, is not just "more a pallet" so simple.

Three core advantages of pallet conveyor lines

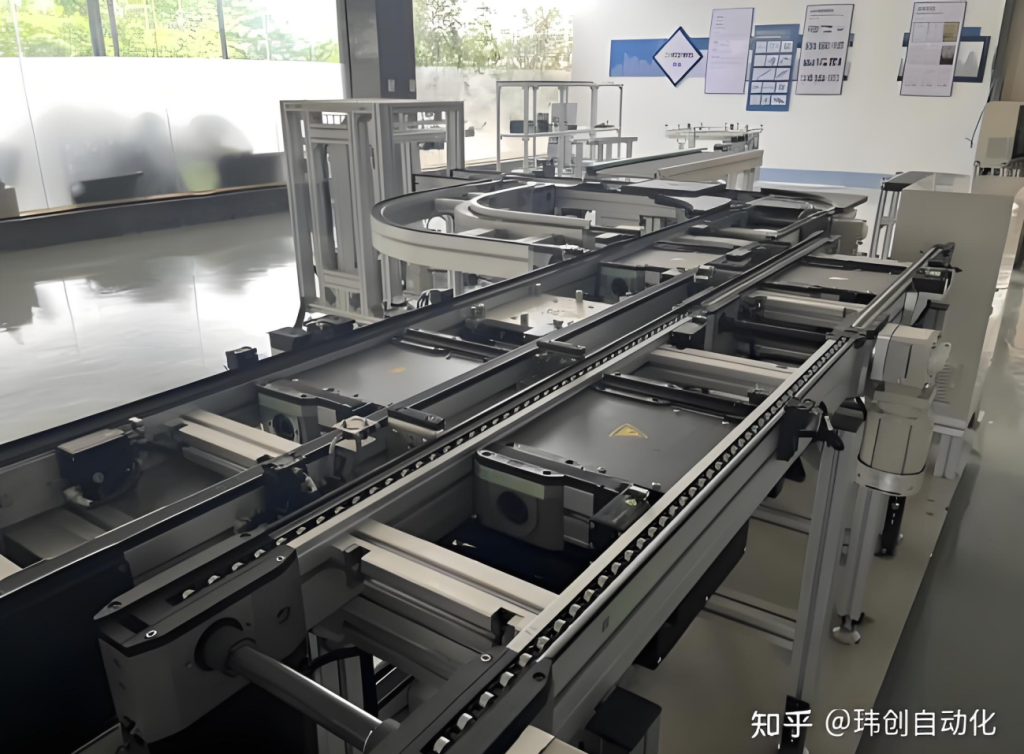

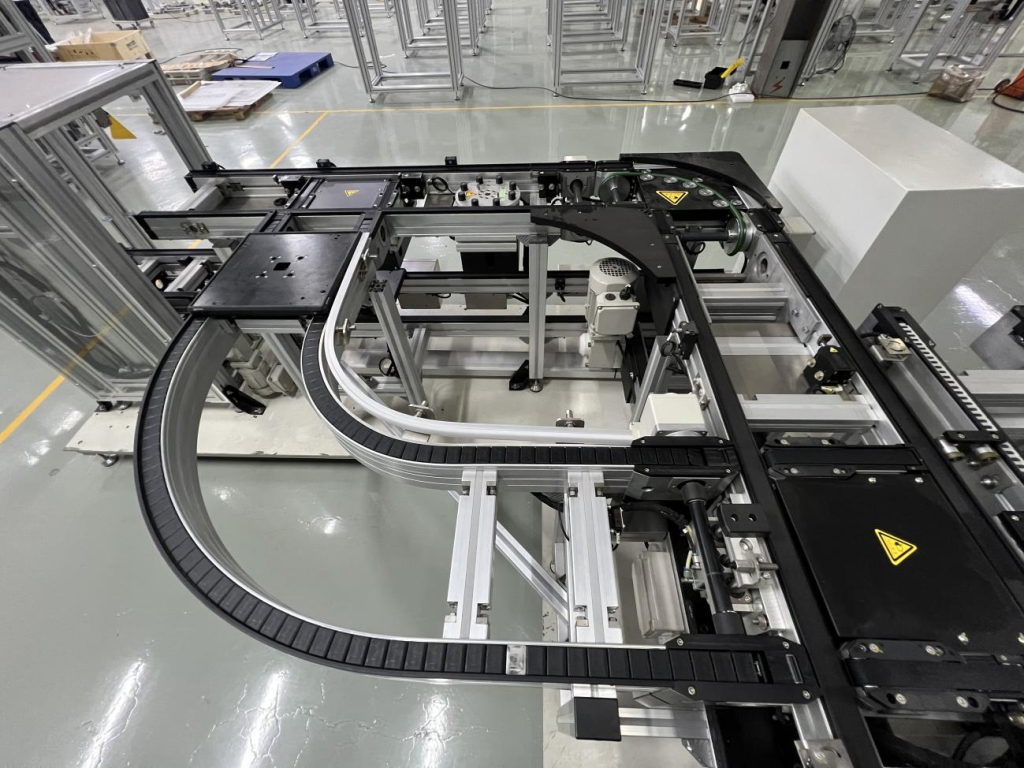

1,Modular design for flexible adaptation to complex scenarios

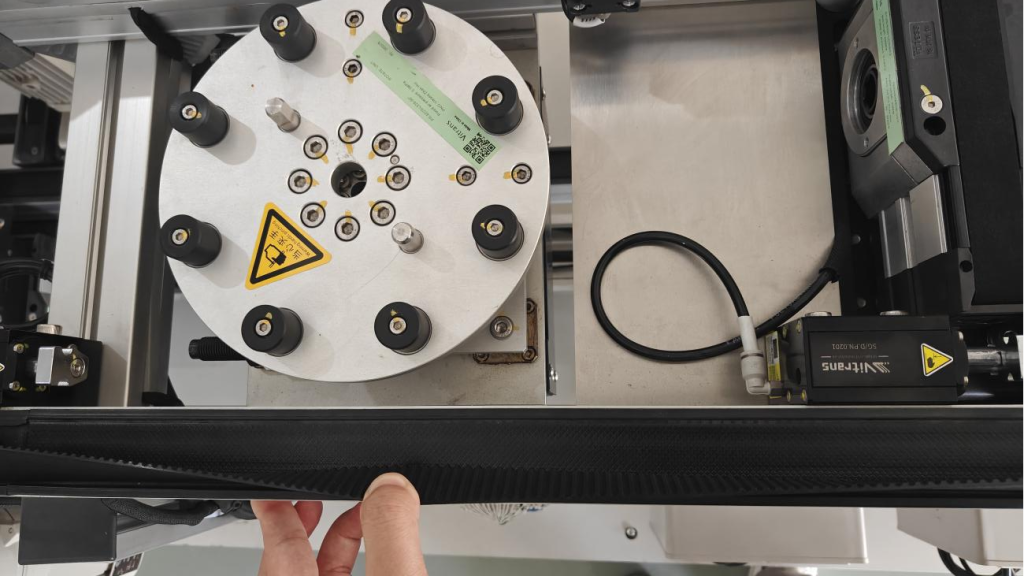

legacyleather belt lineSingle function, and Wei Chuang pallet conveying system using theModular design(curves, jacking traverses, hoists, etc.), can be quickly combined into solutions adapted to different production rhythms and spatial layouts. For example, in the automotive manufacturing industry, the jacking and positioning unit (repeatability of ±0.1mm) and the forced turning mechanism can achieve high-precision, multi-angle workpiece flow, which is beyond the reach of ordinary belt lines.

2,Load Capacity and Accuracy

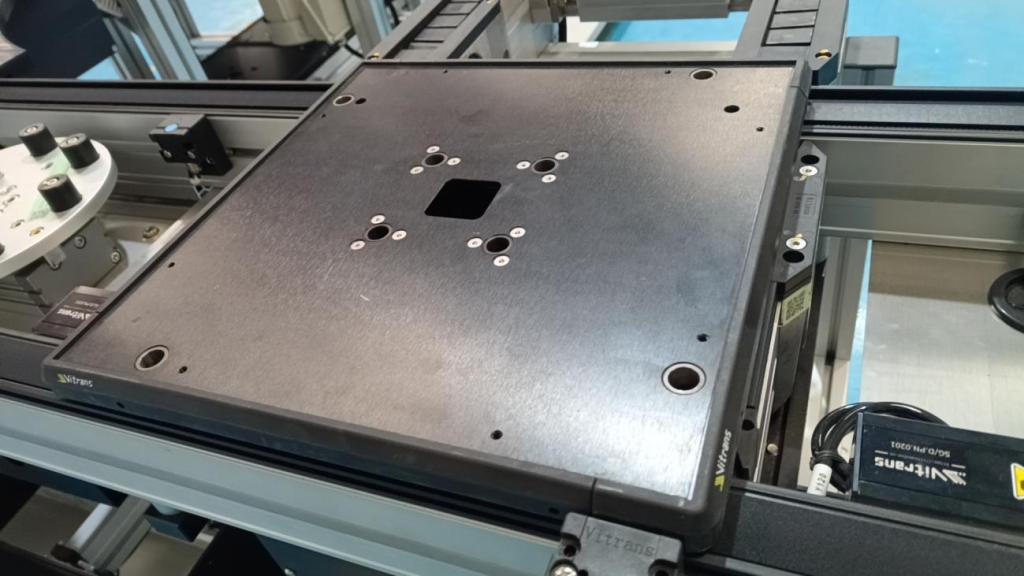

The synchronous belt, flat belt and other media of the pallet conveyor line are specially designed for pallets, with significantly increased load capacity (e.g., 250kg load for a single section of the flat belt, and up to 4,000kg for the doubled speed chain). At the same time, the pallet is embedded with positioning pins (accuracy ±0.05mm) and guide grooves to ensure that the workpieces remain stable during high-speed conveying, which is especially suitable for demanding scenarios such as automotive parts.

3,More Intelligence and Scalability

Pallet systems support customised packages such as robotic loading and unloading, high temperature conveying, etc., whereas traditional belt lines usually only perform basic conveying tasks.

for exampleWhat is the difference between the versions on pallet conveyor lines with the same timing belt?

Pallet Timing Belt Conveyor Line::More precise and efficient

1. Optimised for trays:Increased load capacity to 60kg (conventional)Beltline timing belts(usually ≤20kg), and the load limit per unit length is up to 1kg/cm, ensuring long-term operational stability.

2,Bidirectional transport capacity:While traditional belt lines are mostly unidirectional, the synchronous belts of the pallet system support forward and reverse operation, adapting to complex process layouts.

3,Modular drive design:The motor mounting position and angle can be flexibly adjusted, and it supports extended functions such as anti-static and stacking operation, which are difficult to realise in ordinary belt lines.

Applications: from 3C electronics to automotive manufacturing

Pallet conveying lineThere is a crossover with traditional belt lines in industries such as 3C electronics and shoe making, but in theautomobile manufacturingIn the field, pallet systems are particularly advantageous:

- Body welding line:High loads (e.g. up to 240kg for WE2 pallets) and jacking and positioning functions for high-precision flow of heavy workpieces.

- Battery Packaging Match:Efficient joining of multi-layer line bodies is achieved by means of a hoist (speed 500mm/s), which cannot be supported by ordinary belt lines.

- Harsh Environment Adaptation:Stacked Roller Chain Conveyor LineResistant to oil and dust, whereas conventional belt lines are prone to wear and tear in similar environments.

concluding remarks

Plain old belt line, finally for thePallet conveying systemsDo "assist". Its modular design, high load capacity and intelligent expansion, so that accurate conveying has become a habit of the production line - whether it is the lightweight needs of the electronics industry, or automotive manufacturing of the harsh working conditions, the pallet conveying system can deliver full marks.