In factory production, warehouse sorting and these places, roller conveyor lines are often used to move boxes, parcels, pallets of these goods. Many people who are just starting to contact, do not know which type to choose, what material to use. Today, we will start to talk about the classification and selection of roller conveyor lines, so that novices can also understand.

One,First things first: what are the types of roller conveyor lines?

roller conveyorThere are several types by different aspects, each suited to different needs:

By drive type

- Powered roller line: with its own motor, it can automatically drive the goods to move, suitable for places that require fast-paced conveying, such as when the production line has been feeding materials.

- No power roller line: there is no motor, either by the weight of the goods themselves sliding away, or rely on people to push, suitable for short distances, moving not heavy things, such as the warehouse unloading temporary transfer of goods with.

- Accumulation roller lineThe roller is a special "layered" design, where the middle shaft rotates but the outer layer does not, allowing the goods to stop at a specified place, suitable for scenarios where the goods need to be controlled to stop at a fixed position, such as the assembly of parts at the workstation.

According to the form of the line

- Horizontal drum line: the most common type, the line is flat and carries goods in the same plane, for example, moving goods from area A to area B in a workshop.

- Turning roller line: the line body with a corner, can make the goods to change the direction of movement, suitable for the site has obstacles, need to go around the situation, such as warehouse corners to turn the goods when used.

- Inclined drum line: the line has a slope, either sliding by the weight of the goods (unpowered) or driven by a motor (powered), suitable for transferring goods between places of different heights, such as moving goods from a first floor warehouse to a ground floor workshop.

Two,Choosing the material: which is the best one to use for the bracket and the roller?

Choose the right material, the conveyor line is durable and save money, depending on where you use it and how strong it needs to be:

| character radical | Material Options | Applicable Scenarios |

| brackets | Aluminium profiles | Where there is a need for frequent disassembly and reassembly, or where the environment is dry, such as the production line of an electronics factory. |

| steels | To move heavy things, where there is a high demand for strength, such as when heavy industry moves heavy pallets | |

| stainless steels | Places where the environment is humid and prone to rust, such as food factories, chemical plants | |

| platen | Plastics (PL) | Moving things that aren't heavy, like couriers sorting small parcels |

| Carbon Steel Chrome Plated (CP) | Moving medium weights and a bit of rust resistance, such as moving cardboard boxes in a normal warehouse | |

| Stainless Steel (SS) | Where the environment is humid, prone to rust, or where food requirements need to be met, such as seafood warehouses and food processing lines | |

| Overmoulding (RU) | Need non-slip, or afraid of goods touch the place, such as moving fragile goods, glass products when the |

| Carbon Steel Chrome Plated (CP) | Moving medium weights and a bit of rust resistance, such as moving cardboard boxes in a normal warehouse | |

| Stainless Steel (SS) | Where the environment is humid, prone to rust, or where food requirements need to be met, such as seafood warehouses and food processing lines | |

| Overmoulding (RU) | Need non-slip, or afraid of goods touch the place, such as moving fragile goods, glass products when the |

Three,How are the key parameters set?

When selecting a model, focus on the following parameters and compare them with the requirements and the manufacturer's manual:

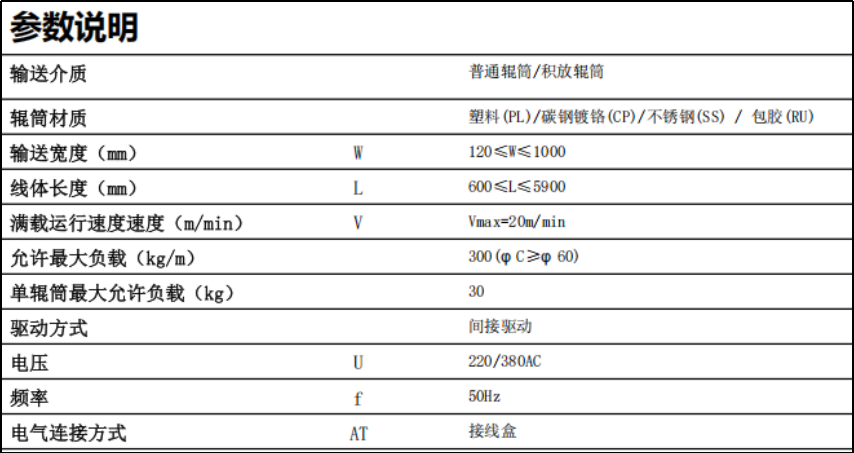

1.Roller length:According to the width of the conveyed goods to ensure that the goods can be placed smoothly on the roller, generally slightly wider than the width of the goods can be. 2.Wire body length:Selected according to the actual conveying distance (see manufacturer's range: Power roller line 6005900mm).

3.Roller spacing:If double row chain drive is used, it should be calculated according to the formula (P=(G×Q)/2, G is the pitch of chain, Q is the number of chain sections), or you can directly use the manufacturer's recommended value, for example, Φ50 drum with 12.7 pitch chain, and the pitch can be 69.8mm, 82.5mm and so on. 4.Load capacity:consultationMaximum permissible load (kg/m) and maximum load per roller (kg).

5.Conveying speed:Choose based on efficiency needs.

Getting the classification, material selection and parameter calculation mentioned above, you can easily choose the right roller conveyor line according to your needs, and moving goods can be more trouble-free and faster!