In a wide variety of production scenarios, ring guide and doubler chain conveyor lines are two commonly used types of conveyor equipment. Because both have the characteristics of chain conveying, some people can't tell the difference between them and can't make up their mind when choosing conveying equipment. In fact, as long as the core characteristics of the two, and then combined with their own needs, you can easily choose the right.

Here are some specific differences between these two types of conveyor lines, and how to pick the right conveyor line according to the actual needs.

Ring guides with doubling chainwireCore differences

Ring guideThough both of them have the part of chain conveying, the applicable scenes are totally different, and there are obvious differences in structure and usage.

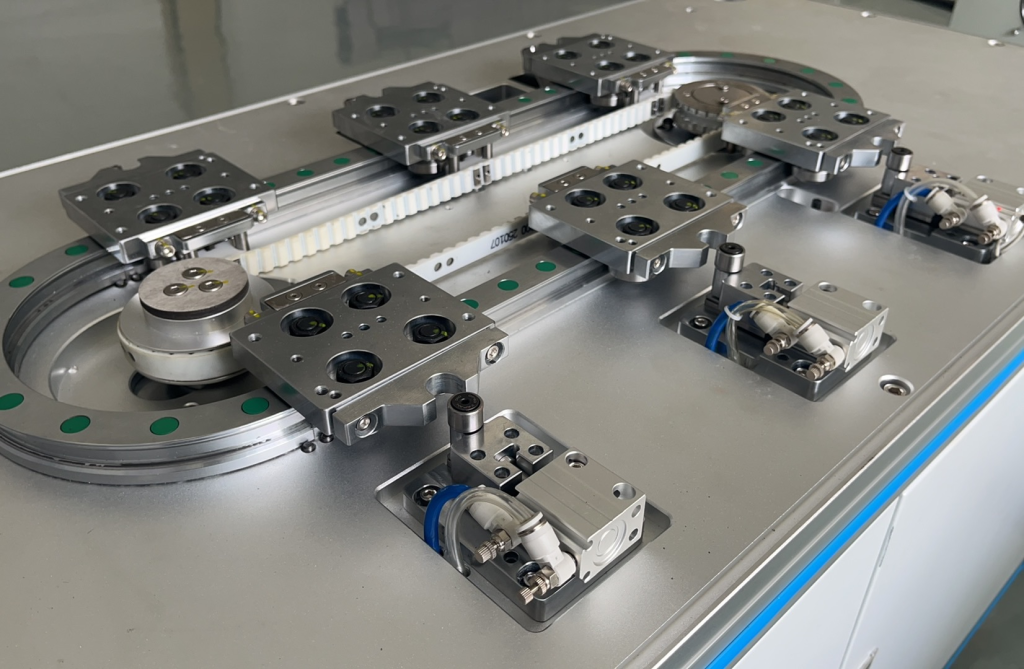

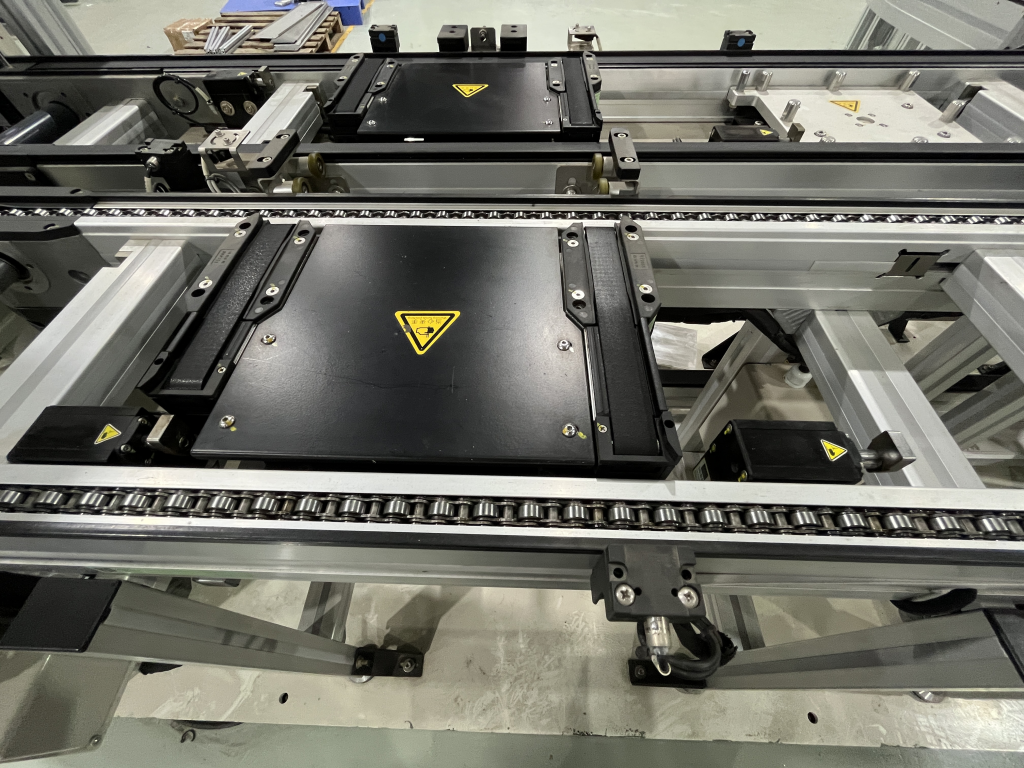

Structurally.Ring guide is a closed loop track, spliced together by linear guide and circular guide, mainly relying on the slider above to move along the track in a circular manner to achieve product assembly or assembly operations. And the doubled speed chain line is basically unidirectional open structure, the material can only be transported in one direction.

From the core strengths.Ring guideways are suitable for production scenarios with high precision, multi-station requirements, and the ability to work in cycles.doubled speed chainthreadsInstead, they are better suited to the needs of low-cost, load-bearing, continuous conveying.

4Accurately match conveyor lines to the key dimensions

After figuring out the differences between the two types of threads, we can judge them against our needs in the following 4 dimensions:

1,Operation mode: whether cyclic multi-station or unidirectional continuoustransmission?

Production requires a number of workstations to work together, such as electronic product assembly, the material to be sequentially through the welding, testing, packaging and other aspects, may also want to return to the starting point after the completion of this operation is recommended to choose the ring guide. It allows the slide with the material in the smooth cycle between the various workstations, so that multiple processes at the same time.

If the production process is simple, the material only needs to be sent from this end of the production line to the end, such as lithium batteries from the assembly section to the packing area, the whole process does not need to turn back, this unidirectional conveying will be used.doubled speed chainthreadsIt's easy to operate and also efficient.

(Image source:Wei Chuang Automation)

2,Precision requirements: High-precision operationRequirements vs. standard accuracy requirements

The materials to be conveyed need to be accurately positioned, such as assembling mobile phone chips, precision instrument parts, which require high stability and positioning accuracy when conveying, it is more appropriate to choose the ring guide.

Just transferring materials, can achieve the accurate stop of the workstation, the standard accuracy of the speed chain line is enough to use, there is no need to spend more money to choose the ring guide.

3,Load size: Is it light and small or heavy material?

Conveying light and small parts, such as electronic components, small hardware, light weight also need to move flexibly, theRing guideThe flexibility is more advantageous, and can easily drive the material to move in a circular manner.

Often handling heavy materials, such as machine tool parts, motors, auto parts and shells, which are heavy and need to be transported stably, the doubled speed chain has a stronger load-bearing capacity, and can hold the heavy materials stably for continuous conveying, and is not prone to overloading problems.

4,Cost budget: seeking value for money orexact match?

With a limited budget, just to meet the basic conveying needs, such as simply transferring materials to a designated location, the multiplier chain line has a much lower quotation and can solve the conveying problem at a much lower cost, which is very cost-effective.

Considering the enhancement of production efficiency, the need to improve production capacity through high-precision, cyclic operation, such as certain precision instruments processing automated production lines, ring guide initial investment is slightly higher, but can reduce production losses, improve process efficiency, long-term use of more cost-effective.

No need to be entangled in the selection of conveyor lines, first clear their mode of operation, precision requirements, load size and budget, and then against the advantages of ring guide and doubling chain, you can accurately match. Choose the right, the conveyor line can really provide assistance for the production, otherwise it is spending money but not get the benefits.