According to the needs of Industry 4.0 logistics development, industrial automation, high speed and intelligence are the trends of the future. And the types of conveyor lines applied in factory automation tend to change according to the usage. Therefore, understanding the different types of conveyor lines and selecting the right conveyor line equipment is crucial for us to streamline the production process and improve productivity.

Let's take Wei Chuang Automation's products as an example to understand the types and uses of conveyor lines commonly used in factories.

1. Beltconveyancethreads

belt conveyorMostly seen in linear conveying. Both flat belt lines and timing belt lines have a wide range of applications in various industries. Often they are more suitable for transporting smaller and lighter components. Widely used in a variety of industries, including the conveying of fast moving goods, food processing, beverages, cosmetics and other products.

The belt conveyor line of Wei Chuang factory is very cost-effective in light load conveying (commonly under 250kg). This advantage is expanding significantly as the level of belt material technology improves.

2. Top Chainconveyancethreads

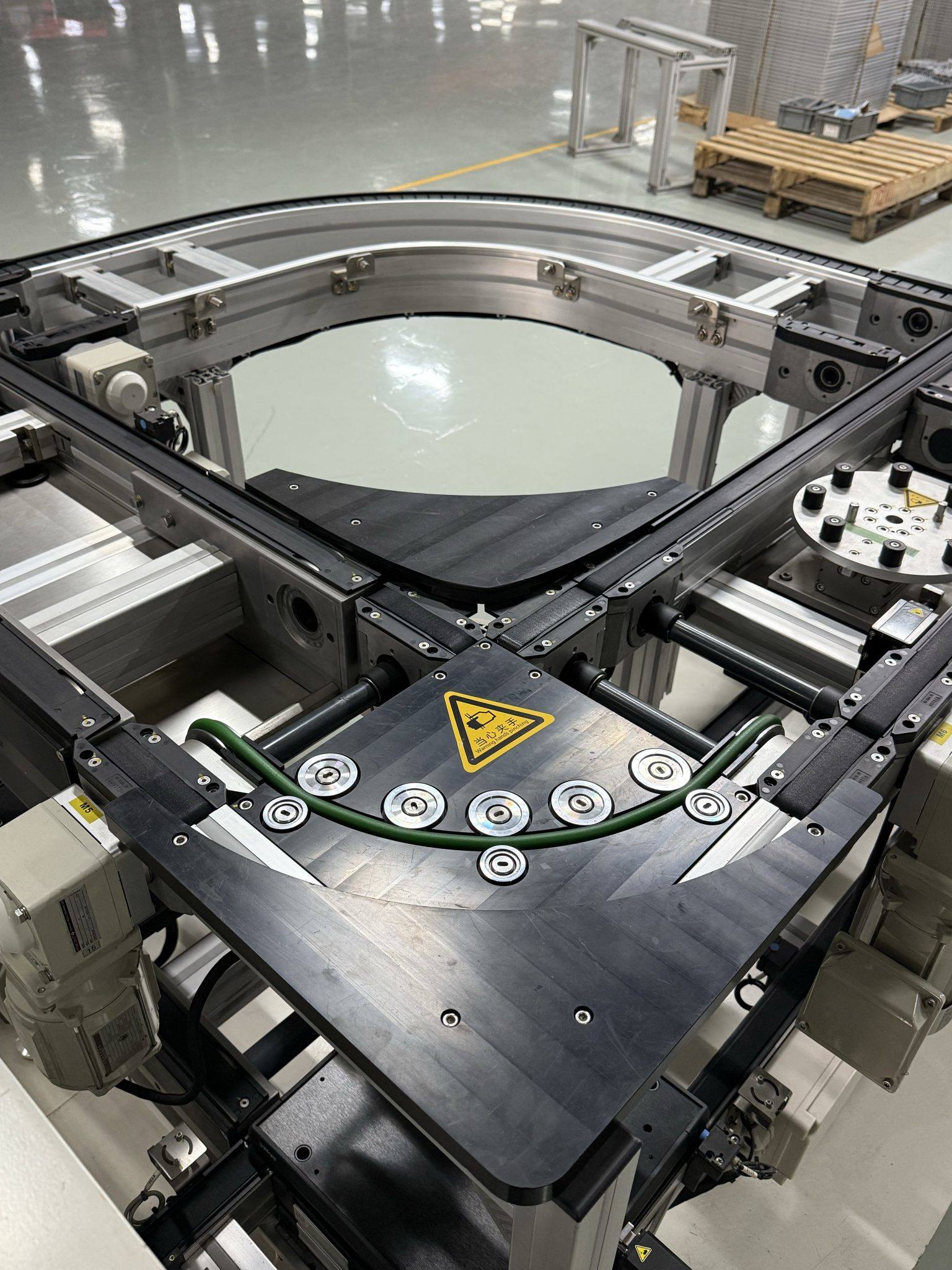

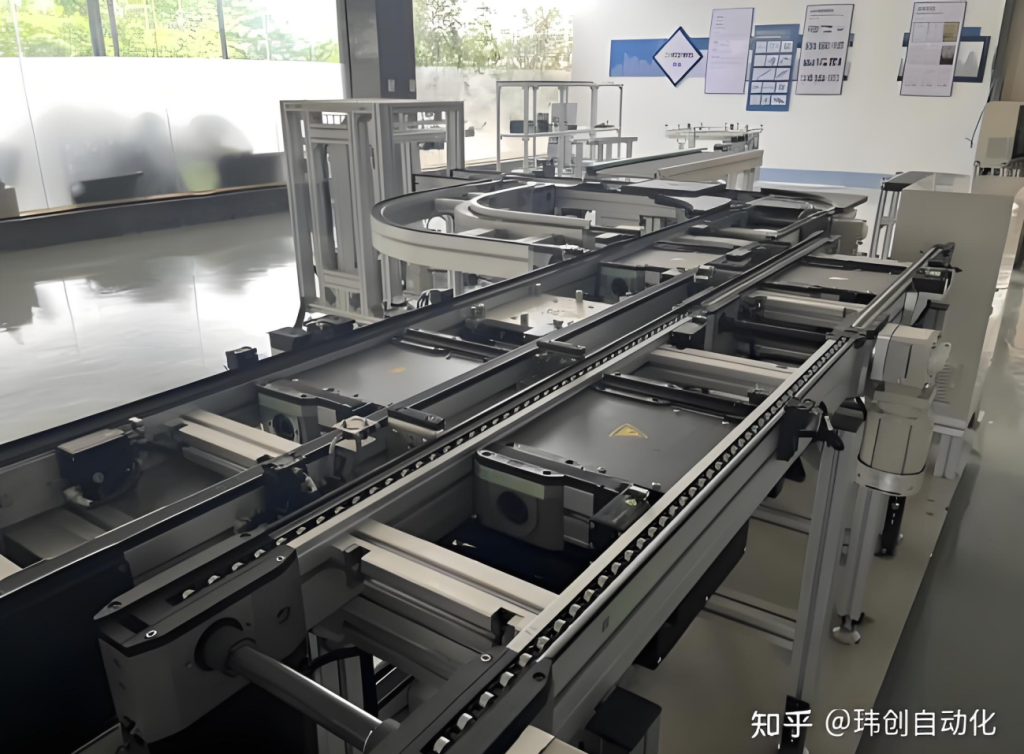

top chainWorkpiece pallets are often required to complement conveying. Because of its unique design, it helps to keep the pallet positioned for greater stability and guidance during conveying.

With a maximum conveying weight of up to 200kg and a very high level of durability and efficiency, this type of conveyor line is ideal for production lines that require a high level of clean environment conveying, such as lithium-ion battery cell assembly, medical device assembly and so on.

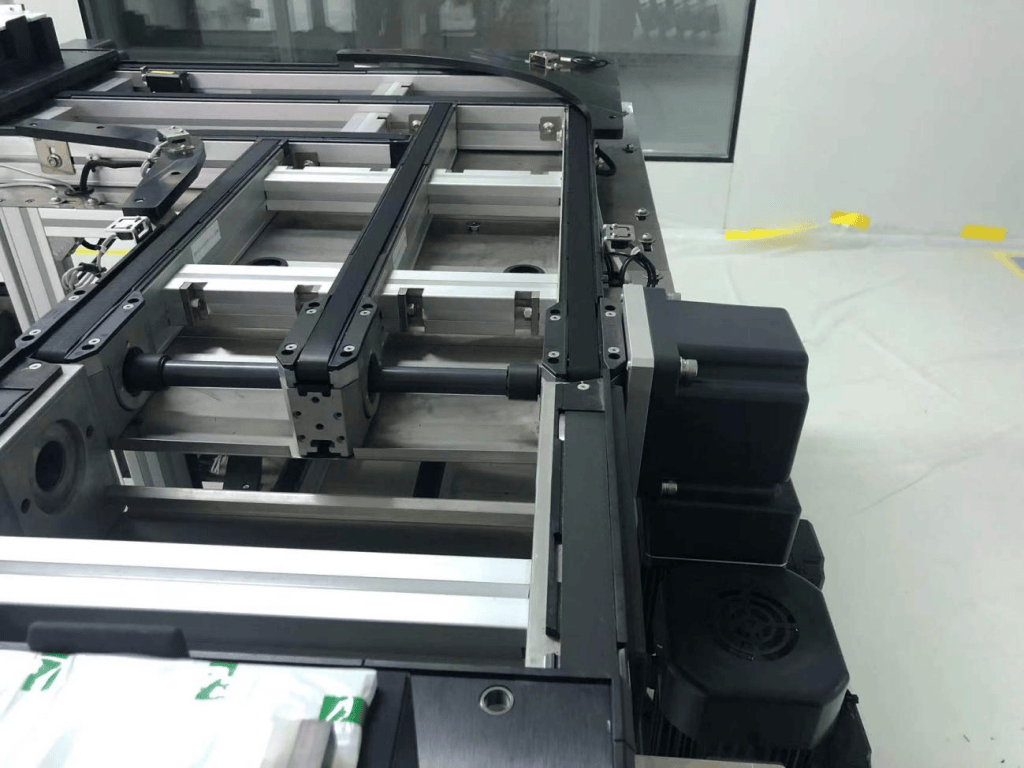

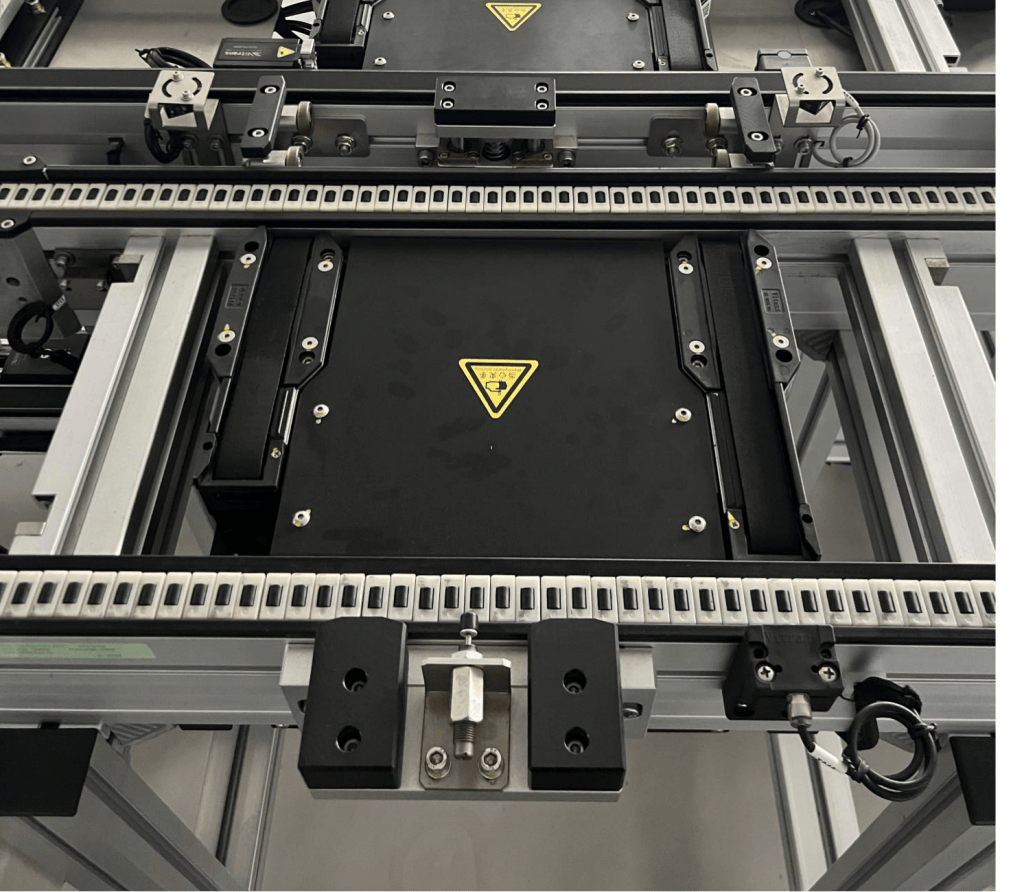

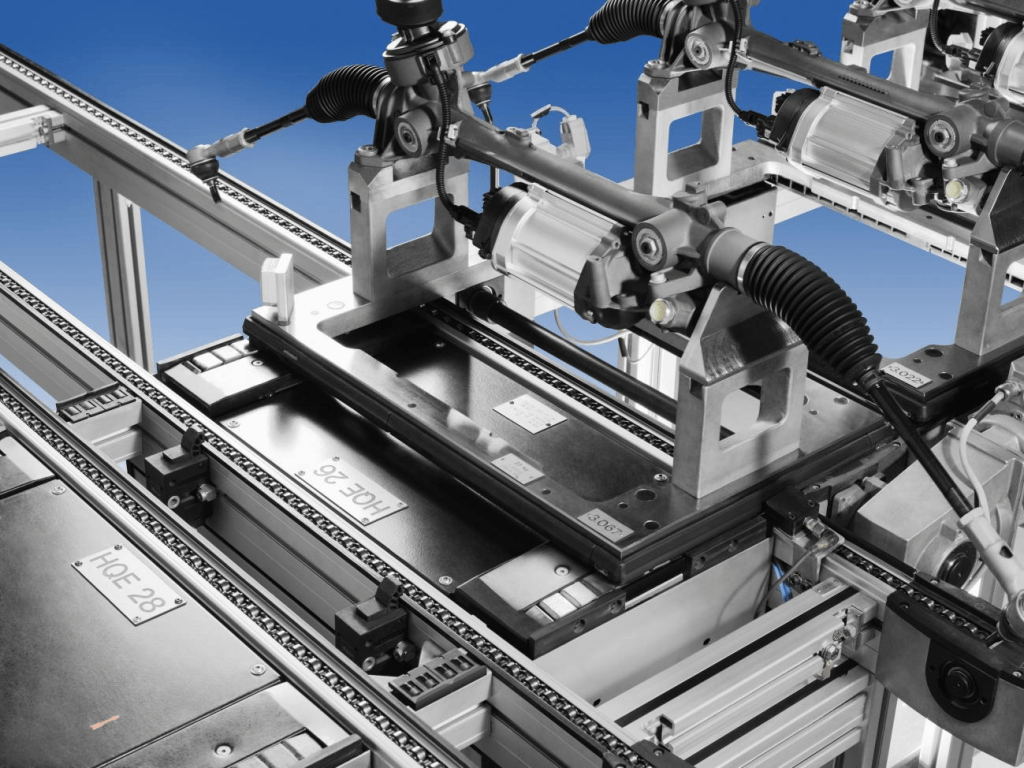

3,Roller Chain Conveyorthreads

Since the chain is mostly rolling friction, it makes theRoller Chain Conveyor LineIt is capable of conveying heavier loads, with light loads of 300kg and 700kg, and heavy loads of up to 2,200kg. For example, long chain conveyor for factory logistics can be designed for long distance accumulation conveyor.

And most roller chains are also bi-directional, making them ideal for commutation applications in automotive battery production and material handling.

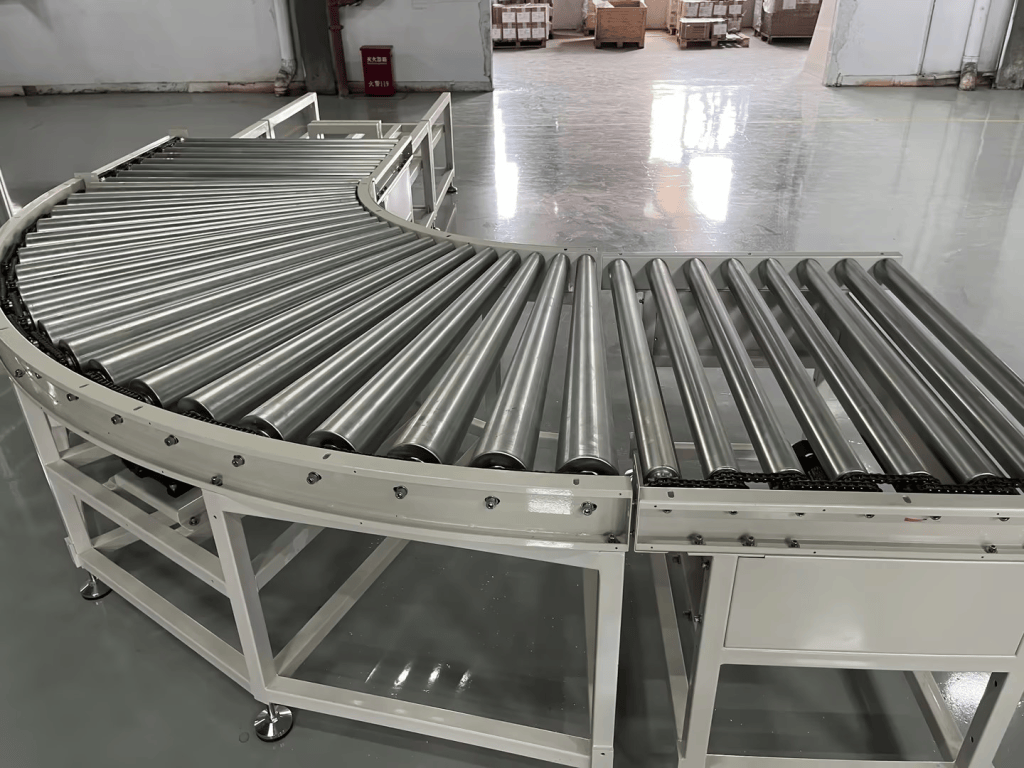

4,roller conveyorthreads

roller conveyorThey usually have a higher load capacity, usually up to 4 tonnes total load. It also provides the widest range of conveying solutions, which are widely used in logistics and warehousing, cargo handling and large material handling.

It has the advantage of significantly reducing manual labour stress and massively increasing throughput. It also has a low overall cost and low maintenance requirements.

Weitron Automation Provides Diversified Services

When choosing a conveying line in many industries, it is also necessary to consider the requirements of the production environment, such as noise pollution, cleanliness level, high temperature and humidity. Wei Chuang's conveying line will be designed and installed with various considerations to ensure that it can meet the conditions required by customers. The contact materials will be wear-resistant, corrosion-resistant, non-shedding particles, and the structure will be optimised and upgraded many times to meet the customer's desired line layout requirements.

The final choice of which conveyor line equipment, no matter from which aspect to consider, or should be based on the customer's specific application needs and layout scenarios to decide.