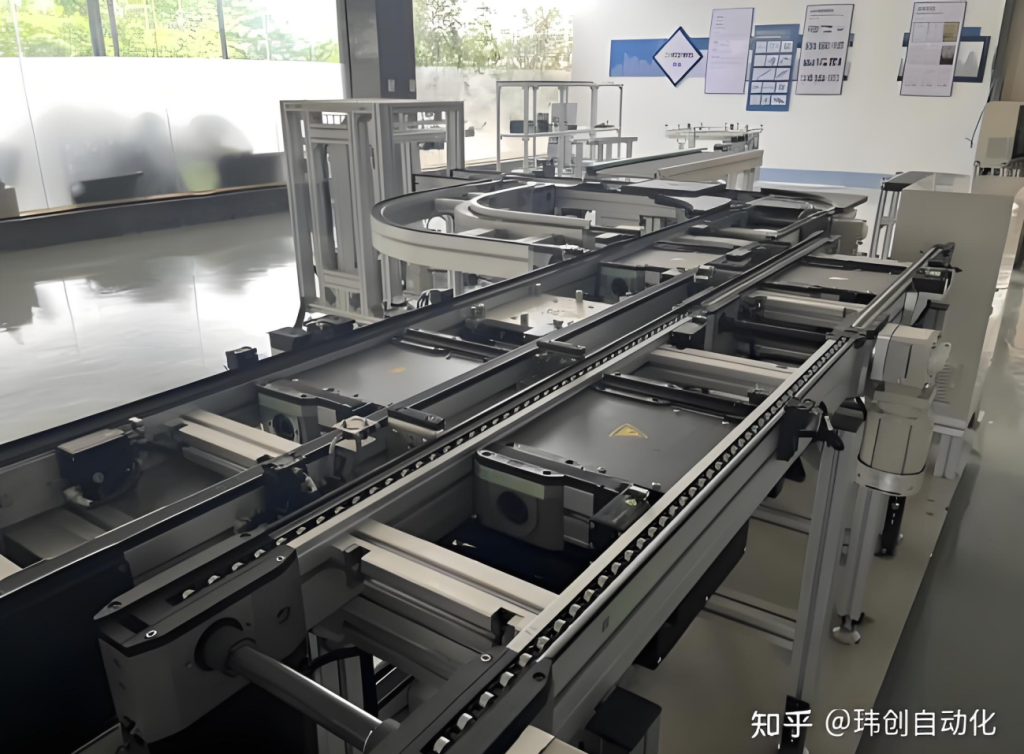

In modern industrial production, the flexibility and efficiency of automation equipment has become the core element of enterprises to enhance competitiveness. AndFlexible chain conveyor lineAs a modular and customisable conveyor system, it is becoming the new favourite for production in various industries with its unique advantages. Today, let us through Wei Chuang's flexible chain plate series, in-depth discussion of how this type of flexible conveying products for enterprises to inject flexible and efficient production power.

One,Flexible chain conveyor line(used form a nominal expression)define

Flexible chain conveyor lineIt is a kind of conveying equipment based on high-strength engineering plastic chain plate and aluminium alloy frame, with the circulating chain as the traction power. It not only inherits the high efficiency and stability of traditional chain conveyor line, but also adapts to the needs of modern industry for complex production environment through modular design and flexible customisation capability.

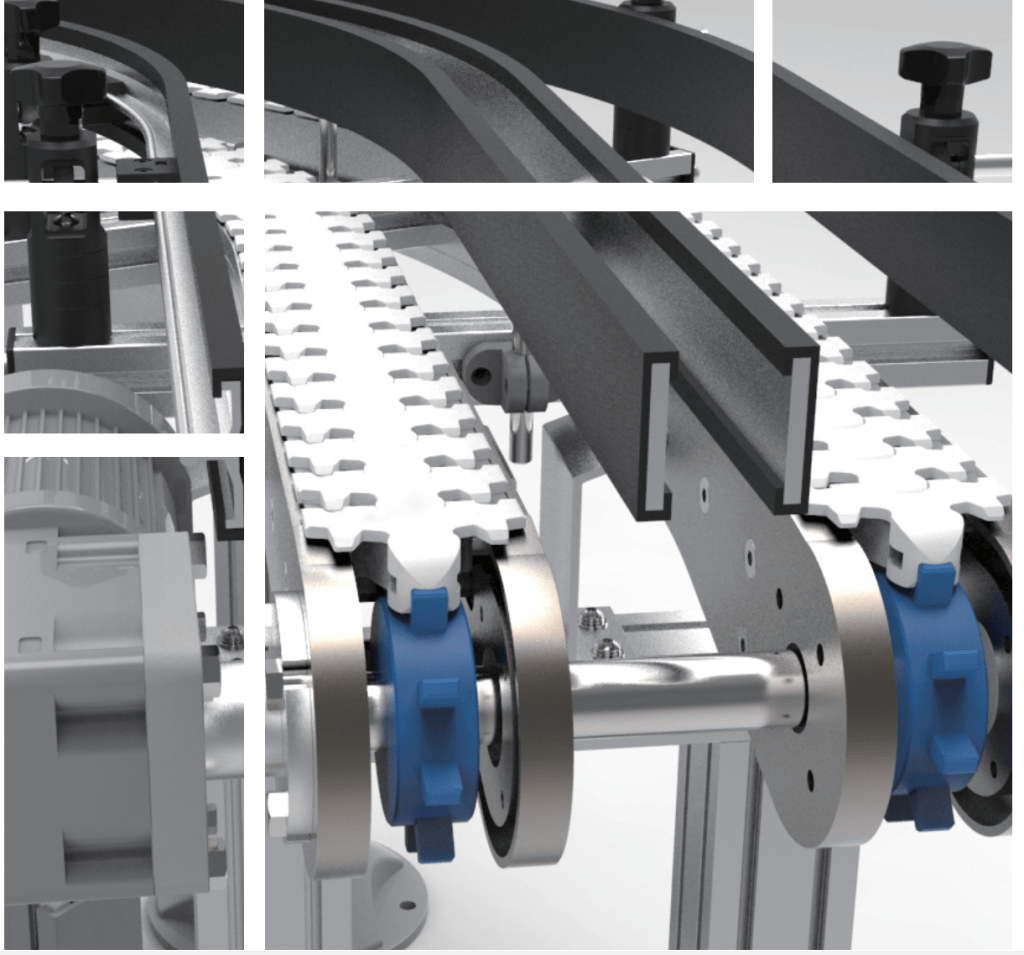

Wei Chuang'sFlexible chain conveyor lineThe core technology lies in the material and structural design of its chain plate. The chain plate is made of modified polyoxymethylene resin (POM) or reinforced nylon (PA6), which has the characteristics of high strength, abrasion resistance and corrosion resistance. Meanwhile, the frame of the conveyor line is made of anodized aluminium alloy profile, which is not only lightweight and beautiful, but also can effectively resist corrosion and abrasion in the industrial environment.

Two,Flexible chain conveyor line of4Big Core Advantages

1. Highly flexible

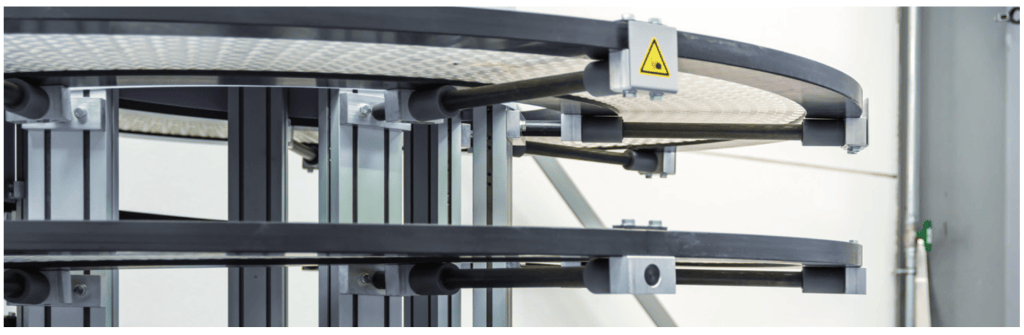

Flexible chain conveyor lineAdopting modular design, the length, width and height of the conveyor line, as well as the turning radius and other parameters can be adjusted freely according to the production requirements, so as to easily realise a variety of complex conveying paths.

For example, Wei Chuang's...Flexible chain conveyor lineSupports a minimum turning radius of 150mm, enabling easy 90° or 180° turns.

2、Stable and reliable

The chain plate and frame of the conveyor line are made of high-strength materials to ensure stability and reliability under high-speed operation. Its running noise is less than 30dB, which meets the clean and quiet requirements of food, pharmaceutical and other industries.

3、Easy to maintain

The structure of the conveyor line is reasonably designed, easy to disassemble and install, no need for special tools, technicians can quickly complete the replacement or adjustment of the chain plate, which greatly reduces the downtime of the equipment. In addition, the chain plate does not need to be lubricated, reducing maintenance frequency and cost.

4. Widely used

Due to its unique advantages, flexible chain conveyor line is widely used in food, pharmaceutical, cosmetic, electronic, automotive and other industries, becoming an indispensable part of automated production line.

Three,Classification of flexible chain conveyor line

According to the different carrying capacity, flexible chain conveyor line is mainly divided into the following 3 categories:

1. Lightweight flexible chain line

It is suitable for conveying light products such as foodstuffs and pharmaceuticals. Smooth running and low noise, especially suitable for industries requiring high cleanliness.

2. Heavy duty flexible chain line

It is suitable for conveying heavy loads such as automotive parts, machinery and equipment. The general carrying capacity is up to 4000kg, wear-resistant and stable.

3. Special customised flexible chain lines

Customised according to customer requirements, pneumatic, electric and motorised self-control devices can be added to achieve more diversified conveying functions.

For example, Wei Chuang's...Flexible chain conveyor lineIt supports a variety of functions such as pallet conveying, diverting and merging.

Four,Industry Applications

l Food industry

Flexible chain conveyor lines are used to convey various food materials and finished products, such as biscuits, candies, meats and so on. Its clean and non-polluting characteristics ensure the safety and hygiene of food.

l Pharmaceutical industry

Flexible chain conveyor lineIt is used for conveying pharmaceutical raw materials, packaging materials, etc. Its GMP-compliant design ensures quality and safety in the pharmaceutical production process.

l Cosmetic industry

Flexible chain conveyor lineIt is used to convey all kinds of cosmetic raw materials and finished products. Its lightweight and beautiful features enhance the overall image of the production line.

l 3celectronicallysector

Flexible chain conveyor lineIt is used for conveying electronic components, PCB boards and so on. Its stable and reliable performance ensures high efficiency and precision in the production of electronic products.

With the advancement of industry 4.0 and intelligent manufacturing, the application scenario of flexible chain conveyor line will be more extensive. In the future, it will not just be a conveying tool, but an intelligent and automated production node. By integrating with robots, sensors and automation control systems, the flexible chain conveyor line will provide strong support for enterprises to achieve a higher level of production automation.

About Weichuang Automation

As a manufacturer of conveyor equipment with 10 years of experience in automation, Wei Chuang is committed to providing customers with high-quality and cost-effective conveyor systems. Whether in the food, pharmaceutical or electronics industry, with years of technical accumulation and industry experience, Wei Chuang can provide standardised products, as well as efficient and reliable conveying solutions to meet the different individual needs of customers.