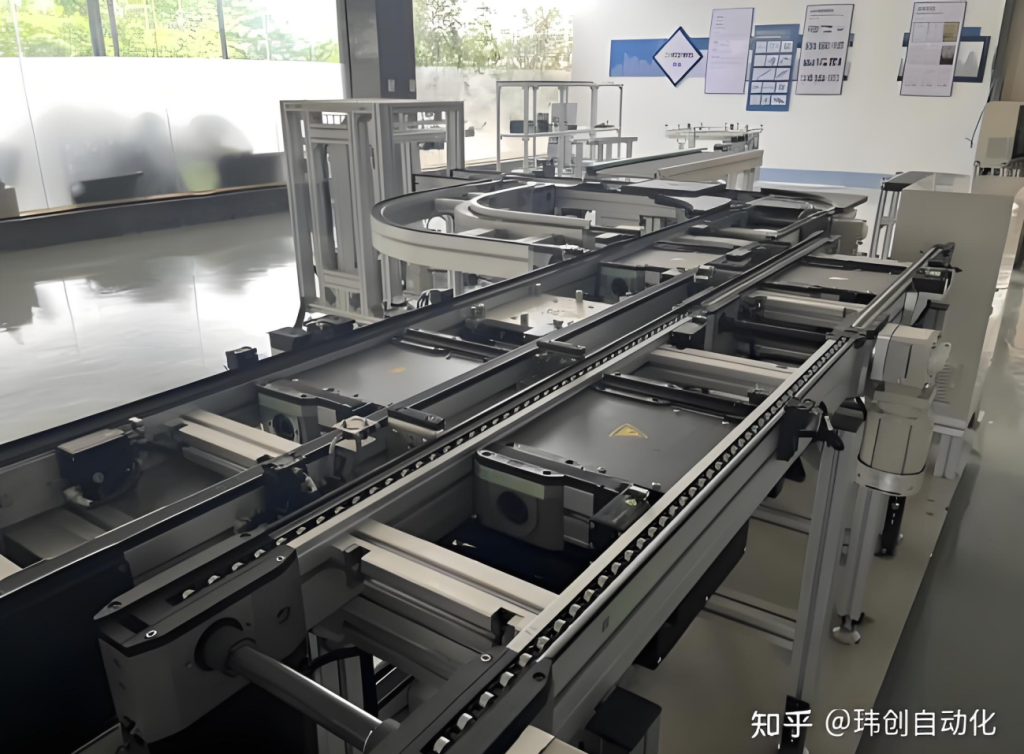

Pallet conveying systemsAs an important support for modern automated production lines, its core function is to deliver pallets of workpieces to various production stations by means of efficient and precise conveying. As an important part of the pallet conveying system, the roller line has become the preferred solution for many industrial sectors due to its high load capacity, flexible beat control and easy maintenance.

Today, we will let you have a deeper understanding by introducing Wei Chuang's Pallet Conveyor Line-Roller series products:

I. Products

The use of rollers as the conveying medium enables the precise conveying of pallets in continuous operation and stackable waiting. The design is highly compatible with pallet materials and styles, and can be adapted to meet the needs of different industrial scenarios.

The main classifications are:

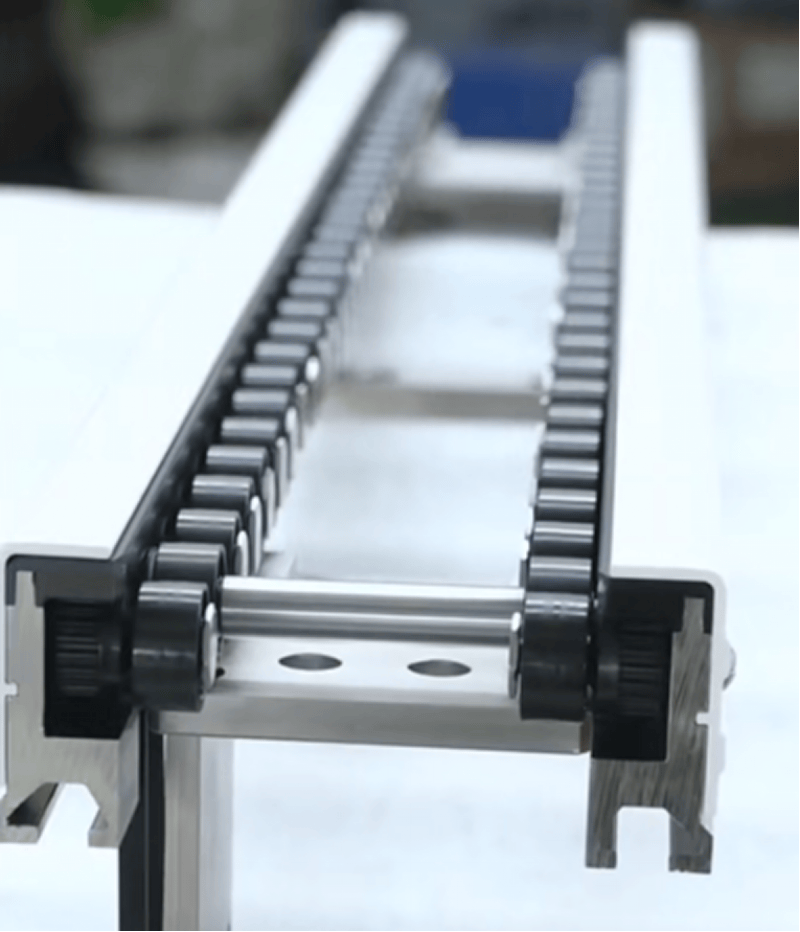

track roller

-Mainly consists of power rollers, drive unit, support frame and other accessories

-Has the advantages of simple structure, easy maintenance, low operating costs, small energy consumption, etc.

-Microcomputer control and centralised control can be achieved, applicable to a variety of different needs of the conveying scene

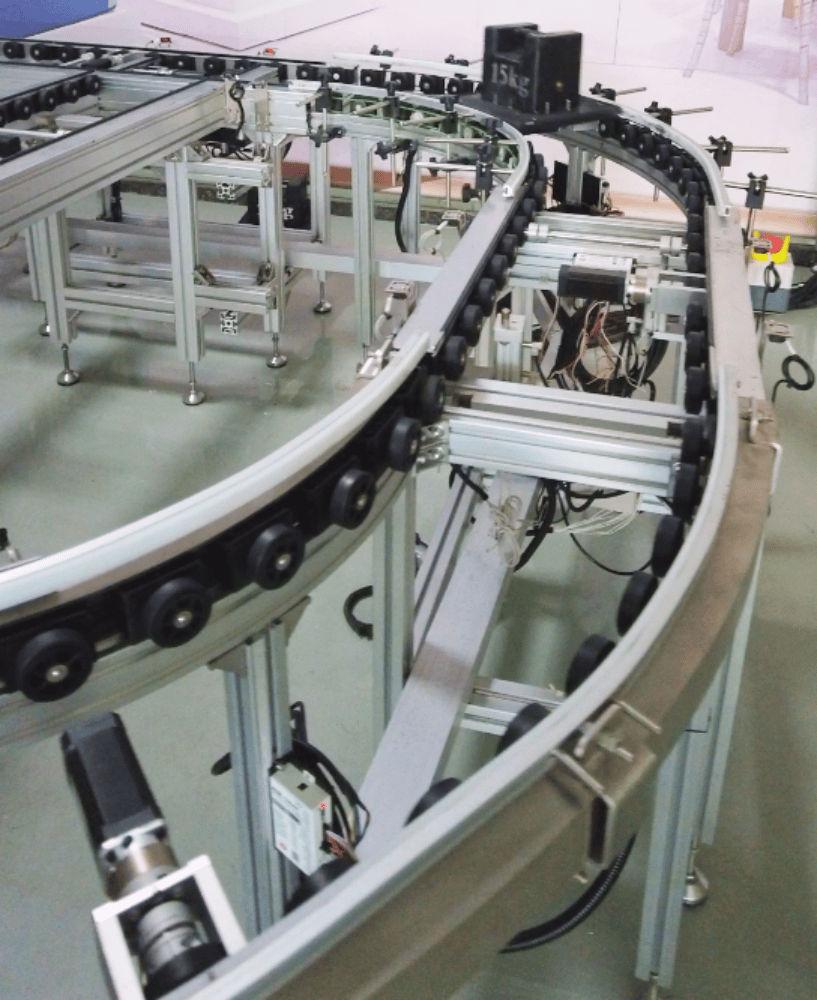

High Speed Roller Line

-Precise transport and positioning of the pallet by means of a start-stop conveyor.

-High speed, high precision, high cleanliness, low energy consumption, no collision and so on.

-Suitable for conveying precise and easy to vibrate damaged materials, such as new energy battery cores, electronic products and so on.

Two,Core advantages of roller conveyor lines

1. Highly efficient and flexible, with adjustable speeds to suit different production rhythms

2. Modular design, freely combinable

3. Simple structure, low failure rate, low-cost maintenance

4. Wide range of loads, can transport boxes, trays, turnover baskets and other carriers

at the same timeHigh speed roller conveyor lineIt also has significant advantages such as high speed, high cleanliness, low energy consumption and no collision, which is especially suitable for conveying materials that are precise and easy to be damaged by vibration, such as new energy cores and electronic products.

Three,application scenario

Roller conveyor lines are widely used in several industrial sectors due to their excellent performance and wide compatibility:

Express logistics sorting:In e-commerce warehouses and express delivery outlets, roller conveyor lines are used for parcel sorting and parcel consolidation.

Manufacturing lines:Roller conveyor lines are used in automotive and appliance factories for the transport of parts and finished products.

Warehouse handling:In three-dimensional warehouses and cold chain logistics, roller conveyor lines connect shelves to workstations for fast transport of goods.

Food processing and electronics workshop::Roller conveyor lines are made of special conveying materials to meet the needs of specific industries

IV. Roller linesSelection Guide

in choosingRoller conveyor lineWhen doing so, the following four aspects need to be considered:

–Define the load requirements:According to the weight and size of the materials to be conveyed, choose the appropriate type and specification of roller conveyor line

–Determine the conveying environment:Consider the environment of the conveyor line, such as temperature, humidity, corrosiveness, etc., and choose the appropriate material.

–Select the drive method:According to the actual needs and layout of the production line, select the appropriate drive mode

–Rational planning and layout:Combined with the overall layout of the production line and space constraints, the direction and length of the roller conveyor line is reasonably planned to ensure the smooth operation of the production line.

Roller line line can be based on different loads to choose the appropriate conveying medium, generally we can combine the load and the limit length to choose the best cost-effective solution when we do the selection.

Weichuang Automation is an intelligent conveyor equipment supplier, mainly engaged in the development, production, sales and service of modular complete sets of customised pallet conveyor lines. Depending on the pallet load, the product has several styles to choose from, such as:Synchronous belt lines, flat belt lines, speed doubling chainslines, etc. Modular design with corresponding control mechanisms to choose from, for example, theBlocker, Positioning, Jacking Traverse(math.) genusliftetc. According to customer's layout, we can build flexibly, shorten the design cycle, and achieve high flexibility and low cost. We have been providing conveyor total solutions for global famous manufacturers in the fields of automobile manufacturing, electric motors, shoes, new energy, 3C electronics, etc.