In the era of Industry 4.0, automated conveying equipment has become the core of enterprises to improve logistics efficiency. As a professional manufacturer that has been deeply ploughing into the automation industry for 10 years, Wei Chuang Automation'sroller conveyorseries products, providing efficient and stable conveying solutions for e-commerce, express delivery, new energy, electronic manufacturing and other fields.

First, the core advantage: directly hit the industry pain points

- Flexible Adaptation

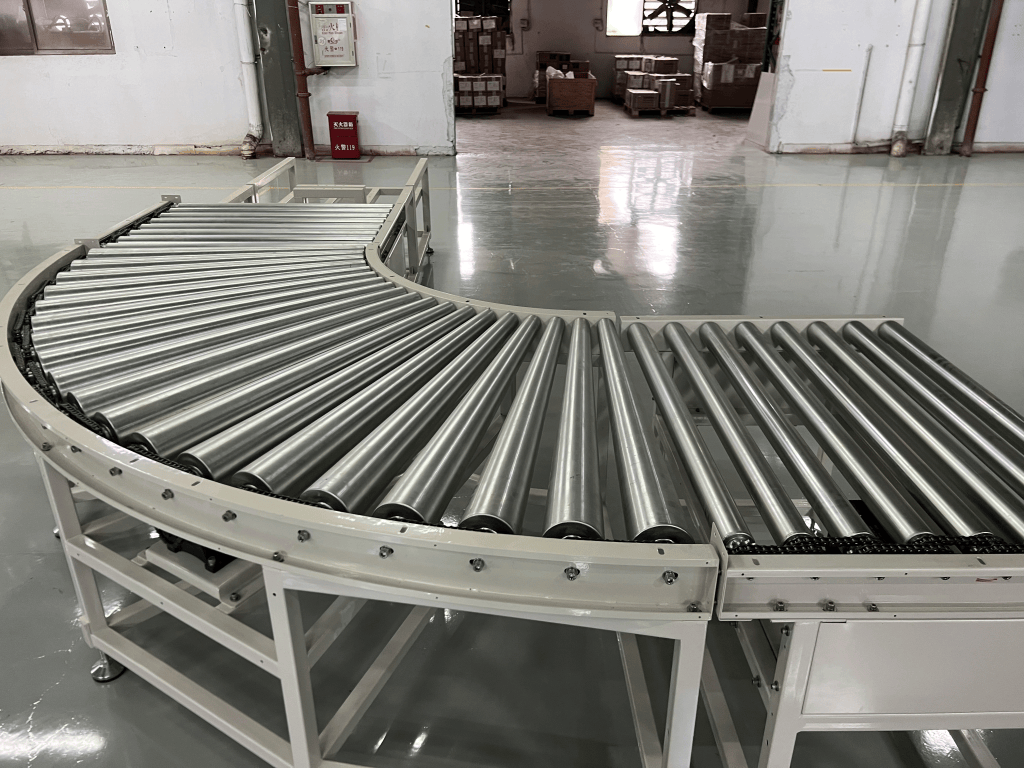

Supporting non-standard customisation, the line body can be designed as straight line, curve, ramp, telescopic and other forms to meet the needs of complex workshop layout.

Roller material can be stainless steel, carbon steel, engineering plastics, the surface of galvanised/cast rubber treatment, anti-corrosion, wear-resistant.

- high efficiency and energy saving

Power system adopts frequency conversion speed control technology, conveying speed 0.5-15m/min stepless adjustment, energy consumption reduced by 30%.

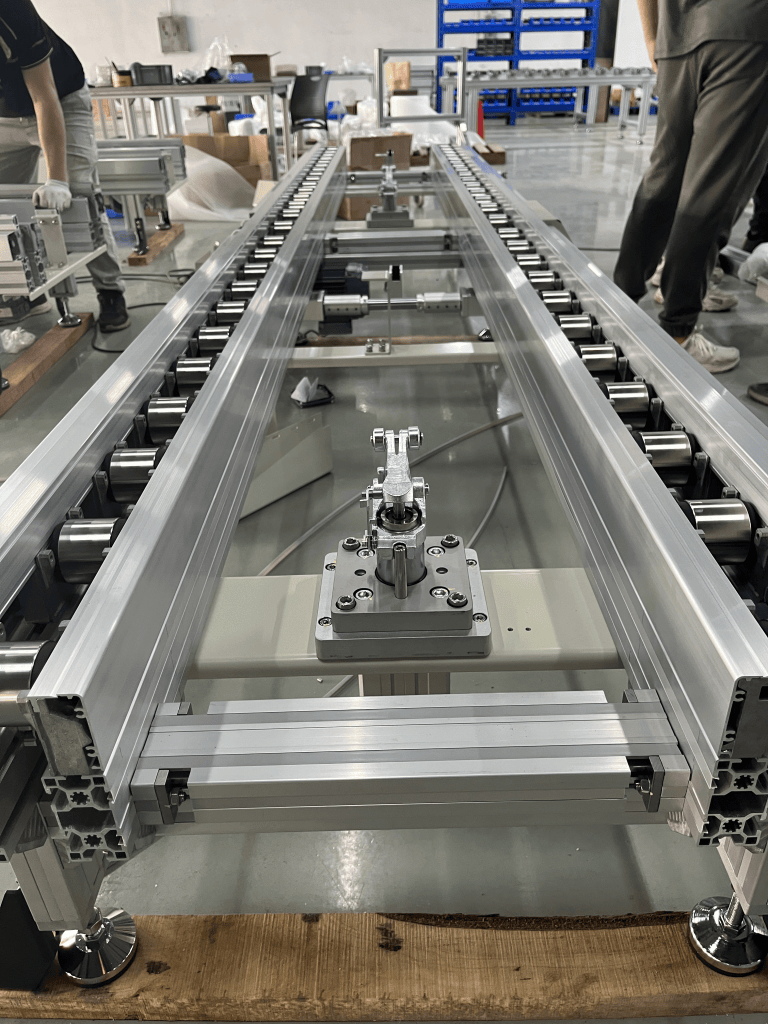

The accumulative design can realise the temporary storage of materials, reduce the frequency of starting and stopping the equipment, and prolong the service life.

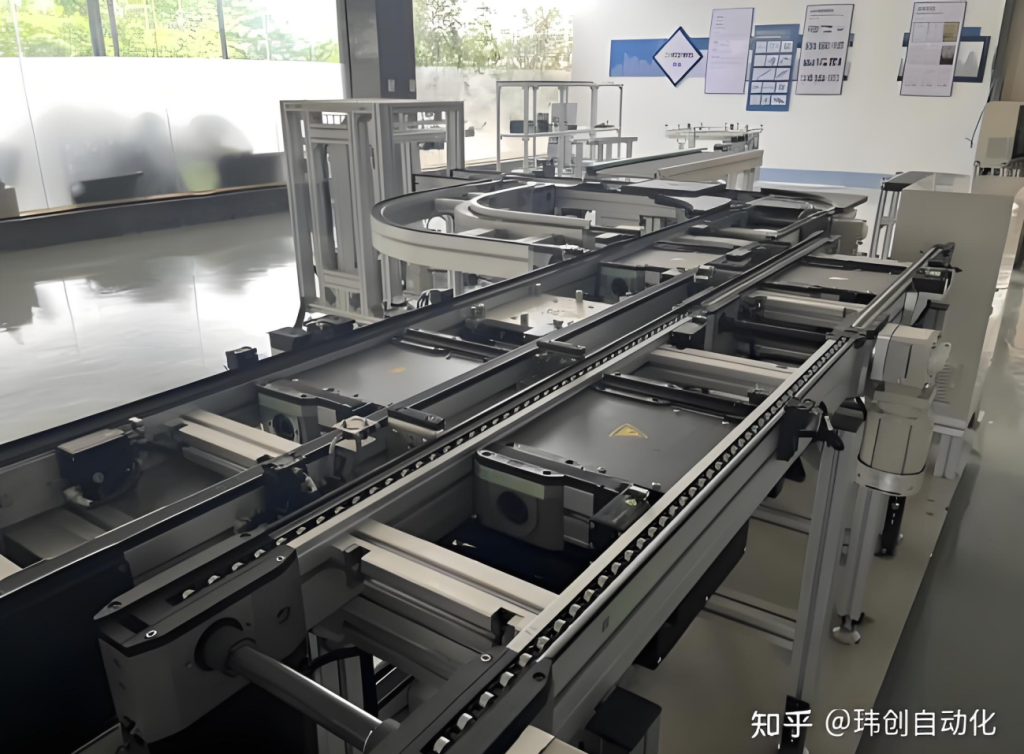

- Intelligent Compatibility

Docking robotic arm, AGV, sorting system, support and MES / WMS data linkage, to achieve full process automation.

Equipped with photoelectric sensors, barcode recognition module, accurate control of material flow.

- stable and durable

The frame is made of high-strength aluminium profile/carbon steel, with a load capacity of up to 2,000kg, supporting 24-hour continuous operation.

Core components are ISO 9001 certified with a failure rate of less than 0.5%.

Second, the selection guide: 3 major types to cover the whole scene

- Non-powered roller line

Applicable scenarios: short-distance manual pushing of lightweight packaging boxes (e.g. picking area in e-commerce warehouses).

-Cost savings: no electric drive required, maintenance costs are near zero.

- Power Drum Line

-Applicable scenarios: heavy-duty pallets, bulk cargo transfer (e.g. cold chain logistics, automotive parts assembly lines).

-Drive solution: drum motor (light load) or motor + reducer (heavy load), precise and controllable conveying speed.

-Applicable scenarios: buffer between processes, assembly line beat adjustment (e.g. electronic product assembly, battery production line).

-Core value: Material stacking through pneumatic/mechanical blockers, balancing upstream and downstream capacity.

III. Industry Application Cases

1. Express distribution centres

Weitron customised a double-drum sorting line for a head logistics company, with a daily parcel handling volume of over 500,000 pieces and a sorting accuracy rate of 99.9%.

- New energy battery workshop

Equipped with anti-static roller conveyor system, it achieves 0 collision flow of battery module, and the yield rate is increased by 15%.

- Intelligent Warehouse System

Roller line + shuttle + three-dimensional warehouse combination of solutions to help customers warehouse ping efficiency increased by 3 times, artificial reduction of 60%.

Fourth, why choose Wei Chuang?

- Customised design:A team of 20 engineers, 72 hours output of 3D layout drawings, support for on-site mapping.

- Full chain of services:One-stop delivery from solution design, production and installation to operation and maintenance training.

- Cost advantage:Scale production + own supply chain, price is 40% lower than foreign brands.

concluding remarks

In the wave of intelligent manufacturing, Wei Chuang Automation always takes "customer needs" as the origin of innovation. Ourroller conveyorIt is not only a material transfer tool, but also a strategic partner for enterprises to improve quality and efficiency. If you are facing logistics bottlenecks, welcome to contact Wei Chuang team for exclusive solutions.