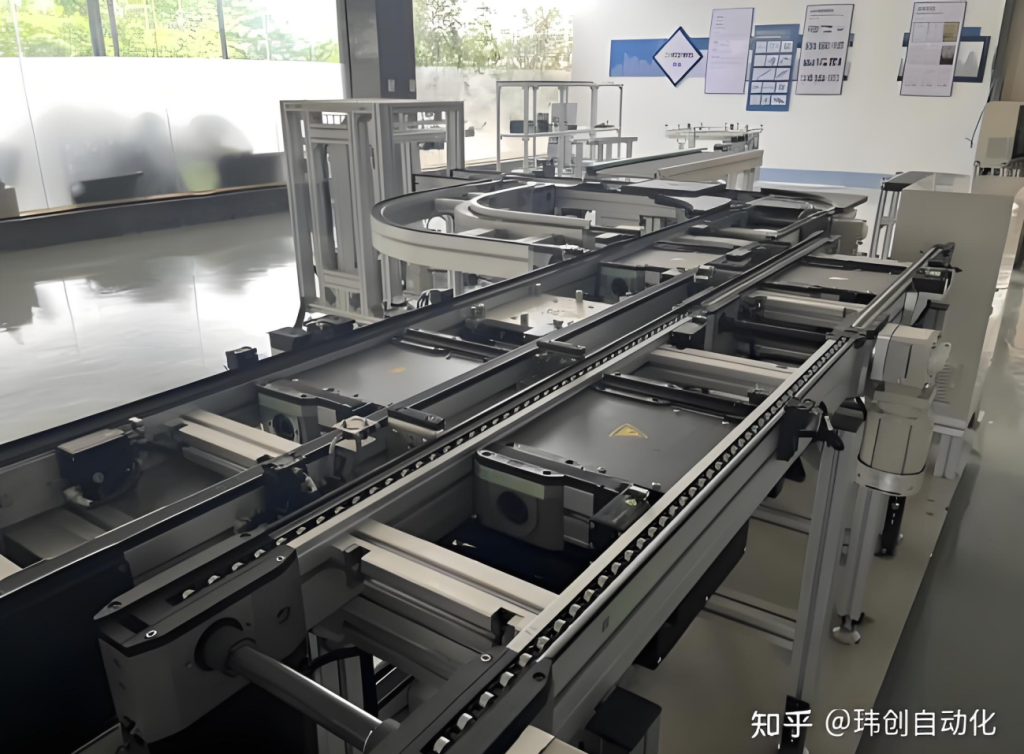

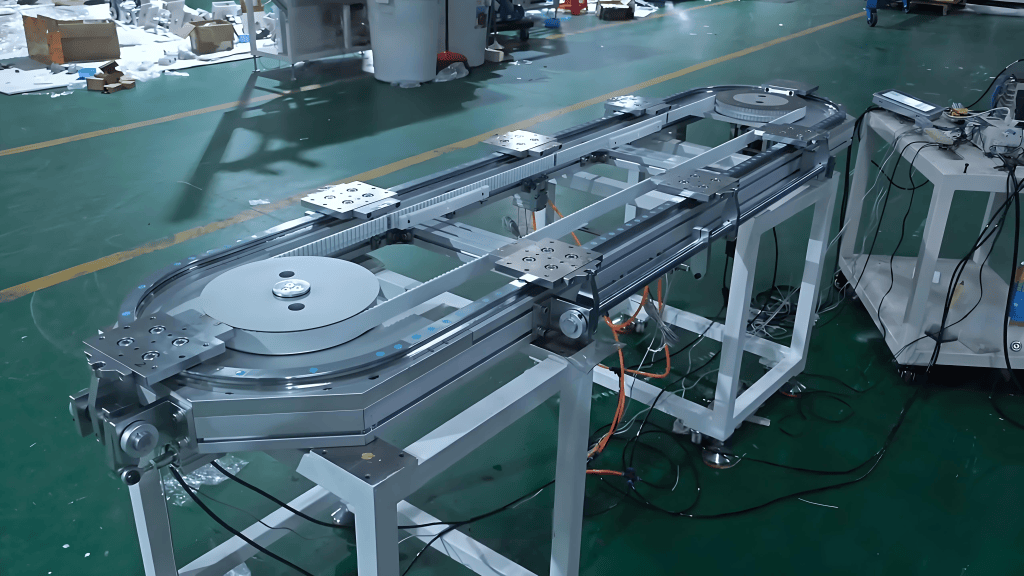

In the wave of industrial automation, theRing guideWith the core advantage of "continuous cyclic conveying + high-precision positioning", it has become the "artery of the production line" in the fields of new energy, 3C electronics, and automobile manufacturing, etc. As the key to its power transmission, the choice of transmission method directly determines the load capacity and operating accuracy, as well as its environmental adaptability. As the key to power transmission, the choice of transmission mode directly determines the equipment's load capacity, operating accuracy and environmental adaptability.

Weichuang Automation has been specialising in modular conveyor systems for many years, and its main series of products areRing guideBased on three mainstream transmission technologies - synchronous belt, chain, linkage - a complete solution covering light load, heavy load and precision scenarios has been formed. This article will unveil the unique advantages of these three "transmission brothers" to help you accurately match the needs of the production line.

One,A technical portrait of the "three brothers" of transmission

1. Synchronous belt drive: silent and light,clean scene

brief outline::Adopting polyurethane synchronous belt (built-in high-strength steel wire core), the power is transmitted through the precision meshing of toothed belt and pulley, achieving no-slip transmission.

Core strengths:

Quiet: the operation noise <60dB, lower than the traditional chain drive 30%, perfectly suited to 3C electronics, medical equipment and other noise-sensitive clean room.

High speed and light weight: the highest line speed can reach 5m/s, single slider load ≤ 10kg, suitable for small parts (such as mobile phone batteries, PCB boards) high-speed flow, to meet the Takt Time <1s compact beat.

-Maintenance saving: no oil, no dust off, no lubrication, service life of 5000 hours or more, reduce the production line downtime maintenance costs.

Typical Scene:Electronic component placement line, precision instrument testing bench, food baking and packaging line (clean and pollution-free requirements).

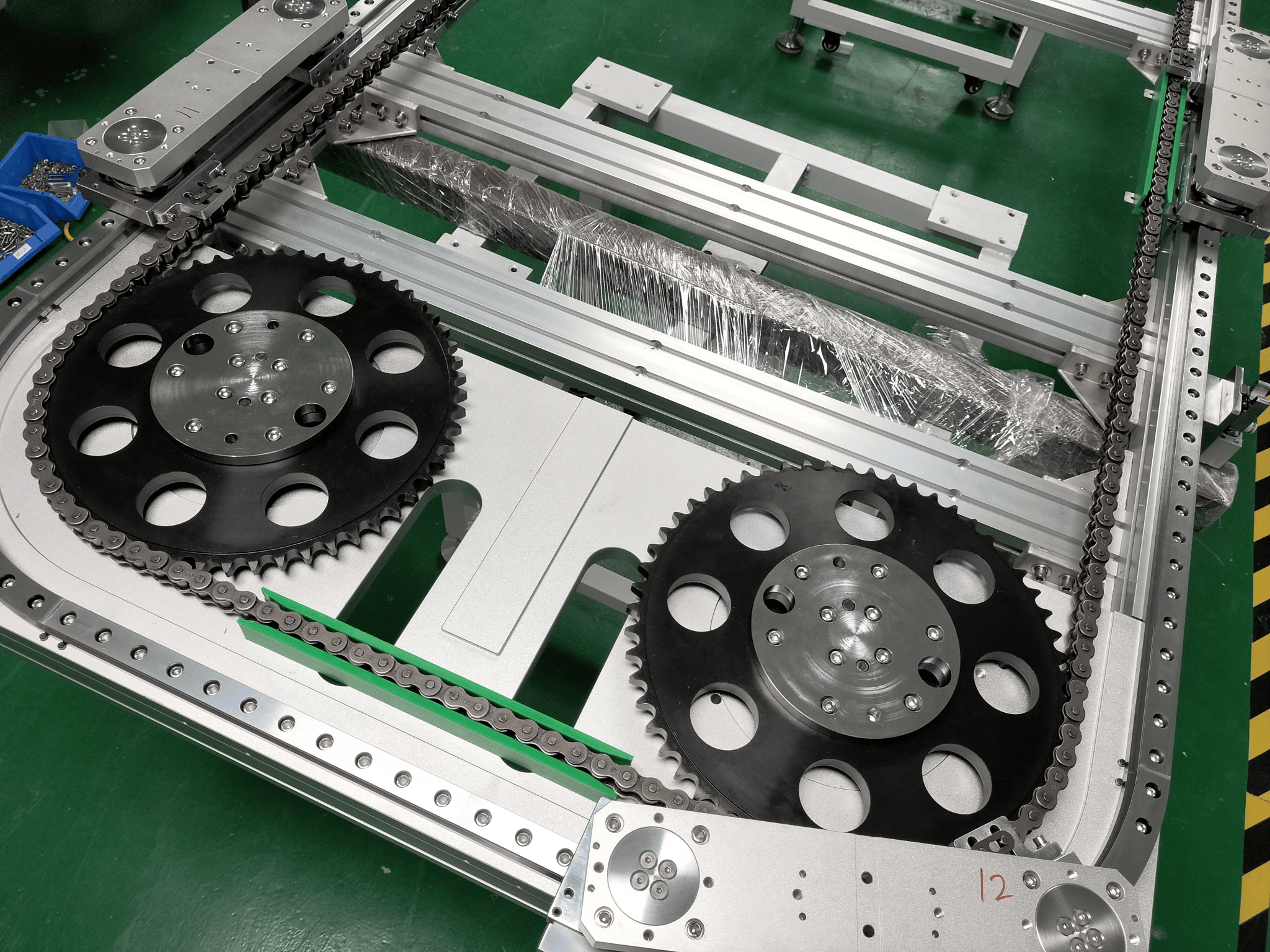

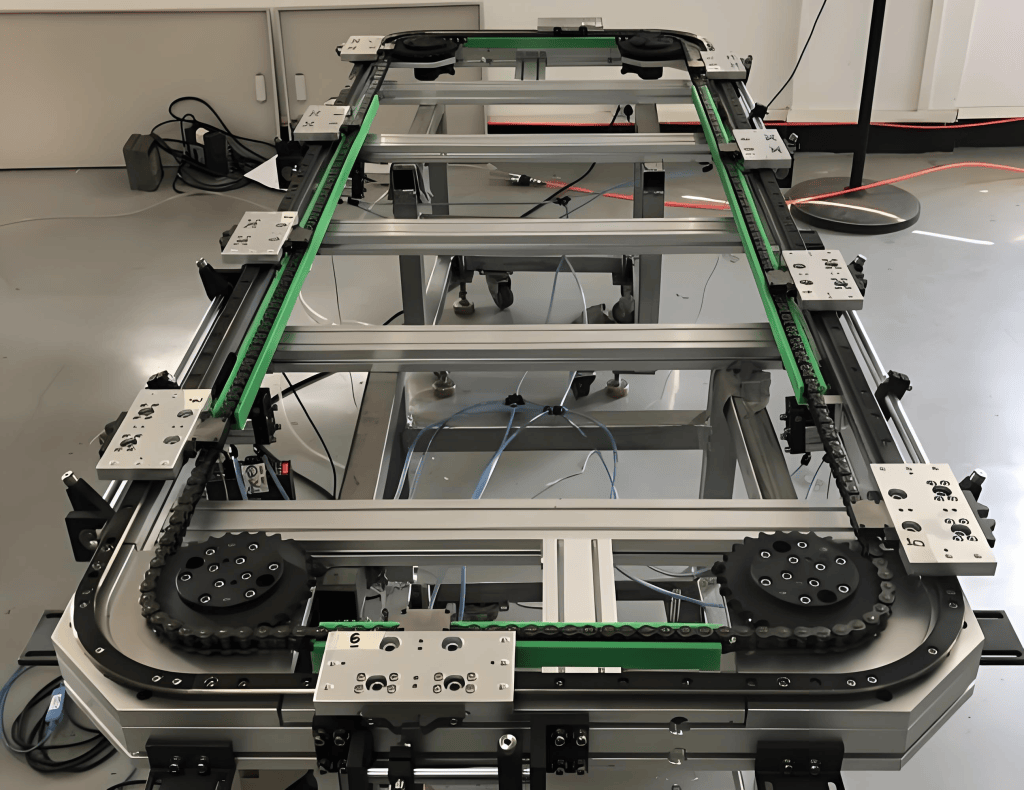

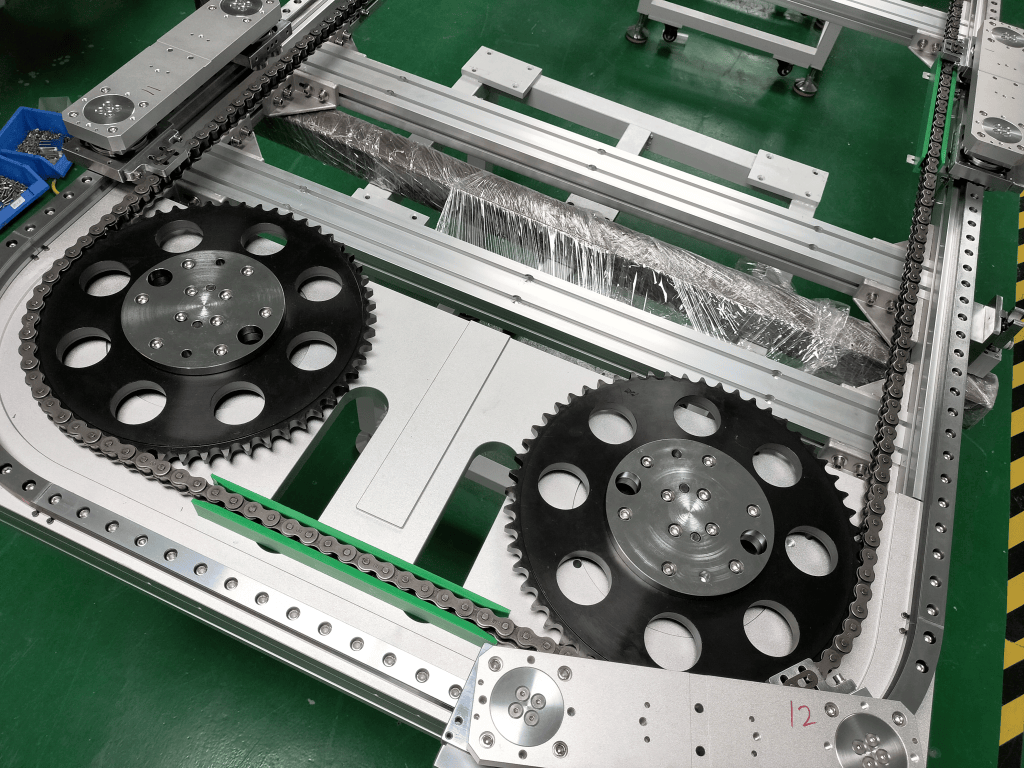

2. chain drive::applicabilityHeavy duty conditions

A brief overview:Selection of high-strengthroller chain(e.g. ISO 606 standard chain), with hardened sprockets, drive the slider through the rigid meshing of chain links and wheel teeth, and the load carrying capacity is increased.

Core strengths:

- Strong load-bearing capacity: single slider load up to 50kg, support large pitch station (maximum 3000mm) and long line (≤ 80m), suitable for automotive engine block, new energy battery module and other heavy materials conveying.

-Durable: galvanised/nickel-plated surface, dust and oil resistant, stable operation in dusty and oily environments such as welding workshops and spraying lines.

-Maintenance friendly: Modular chain design allows for individual replacement of worn links without complete disassembly.

Typical Scene:Automobile assembly line (chassis parts delivery), lithium battery injection workshop (core tray transfer), home appliance shell spraying assembly line.

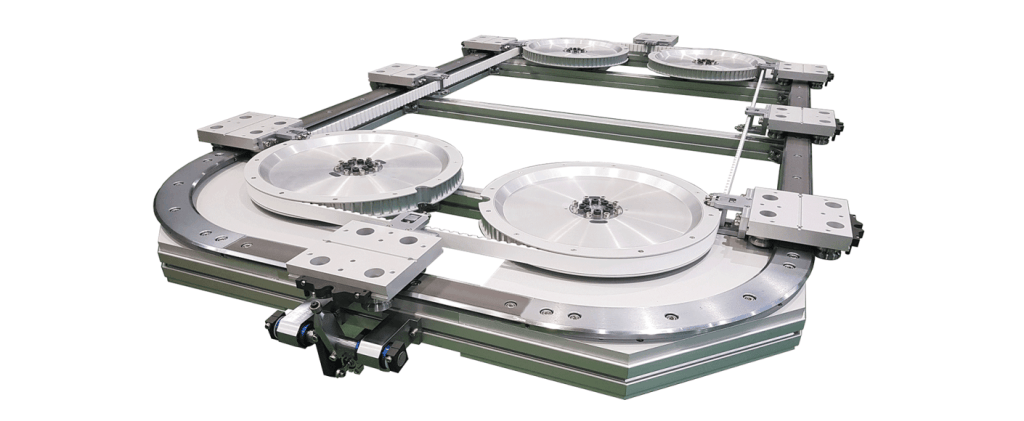

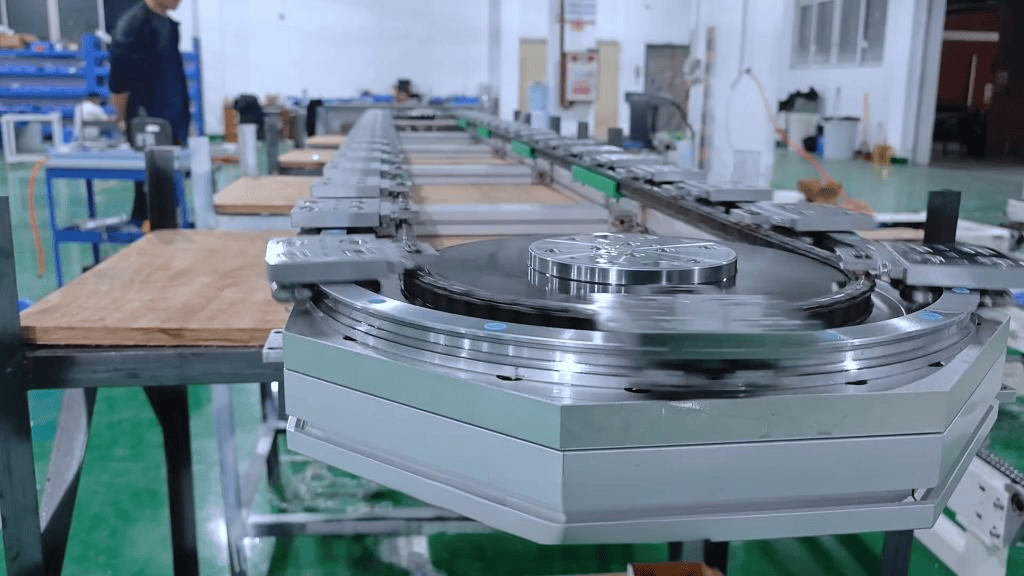

3. Rod drive: precision positioning

brief outline::The slider is connected to the slider through a rigid linkage to form a closed-loop transmission chain, and the mechanical constraints of the linkage are used to counteract the centrifugal force and achieve impact-free and smooth operation in curves.

Core strengths:

-Micron level accuracy: with the high precision positioning mechanism, the repeatable positioning accuracy reaches ±0.05mm, which meets the positioning needs of precision assembly (such as chip packaging, lens module adjustment).

Compact Space Adaptation: Supports small-pitch stations (min. 100mm) and vertical mounting, enabling three-dimensional cyclic conveying inside height-restricted equipment (e.g., mounters, insertion machines).

Low-impact operation: the rigid drive of connecting rod eliminates the impact of belt elastic deformation and chain meshing, the motion curve is smooth, especially suitable for conveying fragile materials such as precision instruments and glass products.

Typical Scene:Semiconductor wafer inspection line, optical lens assembly machine, medical equipment precision parts processing unit.

Two,Ring guide: System-level benefits that go beyond the drive

The three transmission methods can perform well in different scenarios, thanks to the three underlying technology supports of Weitron's ring guide:

1. Rail system: high precision grinding + rigid support

-The guide rails are precision ground to G20 grade, eliminating the risk of slider jamming due to rail deformation;

-Aluminium alloy base with built-in reinforcement structure, anti-vibration capacity increased by 50%, even under high-speed start-stop conditions still maintain smooth operation.

2. Control Technology: Closed-loop feedback + intelligent deviation correction

-Standard magnetic encoder/encoder feedback system, real-time monitoring of the position of the slider, dynamic deviation correction accuracy of ± 0.05mm;

Support multi-station independent speed control (such as chain drive can be segmented speed control), to adapt to the production line of different processes of the beat difference.

3. Environmental adaptability: full-scene protection design

-Timing belt models come standard with a dust cover to cope with dusty environments in cleanrooms;

-Chain terms optional stainless steel + shield to resist acid and alkali corrosion (e.g. battery production electrolyte environment);

-The connecting rod model adopts sealed bearings to avoid lubricant leakage and contamination of precision workpieces.

Three,Selection Tips

To face different production line requirements, you can refer to the following methods:

Step 1: Counting loads

–Light load (≤10kg):Priority synchronous belt drive for speed and cleanliness (e.g. 3C electronics, medical consumables);

–Medium load (1050kg):Chain/linkage on demand - choose chain for large pitch and long distance, and linkage for small pitch and high precision;

–Heavy load (>50kg):Chain drive only (customised reinforced sprockets and guide rails required).

Step 2: Look at the environment

–Dust-free/low-noise scenarios (e.g., laboratories, electronic clean rooms):Synchronous belt drive is preferred, oil-free and maintenance-free;

–Dusty/oily scenarios (e.g., machining, welding shops):Chain drive is more durable and the protective design is anti-interference;

–Precision/compact scenarios (e.g. semiconductor equipment, small specialised machines):The link drive breaks through with its rigid connection and small pitch advantage.

Step 3: Keying in on the details

–Positioning accuracy:Need ±0.05mm level accuracy select link/chain (with positioning mechanism), synchronous belt default ±0.1mm to meet the general installation.Match;

–Linear body shape:Choose chain for oval/rectangular shapes (long-thread advantage), or connecting rods for vertical/circular compact layouts (high space utilisation);

–Maintenance costs:Timing belt (maintenance free) is selected for long term operation, and chain (low cost of link replacement) is selected for heavy load scenarios that receive regular maintenance.

Weitron provides systematic conveying solutions.

As a specialist in modular conveying systems, Weitron not only offers three drive types with standardisedRing guideIt also supports the customisation of the entire chain of "drive + track + control":

- Flexible combinations:The same line can be mixed and matched with transmission methods (e.g. heavy-duty conveyor with chain in the front section and precision positioning with synchronous belt in the rear section);

- Smart Integration:Equipped with jacking rotary unit and visual positioning system, it can realise the integration of "conveying+processing+inspection";

- Industry Deep Dive:We provide exclusive solutions for the high-temperature environment of new energy batteries (optional 150°C resistant material) and the oil-contaminated scenarios of automotive parts (self-lubricating chain design).

concluding remarks

The characteristics of the different transmissions of synchronous belts, chains and connecting rods make up theRing guideThe core competitiveness of covering the whole scene. In today's intelligent manufacturing pursuit of "high precision, high flexibility, high stability", choosing the right transmission method is to install an "accelerator" for the production line. With more than 10 years of experience in the industry, Weichuang Automation can help you break the bottleneck of conveying and make every material flow become the starting point of efficiency upgrade.

Consult us now for your exclusive ring guide drive solution to make your production line "fast" and "stable"!