In the automation industry, which is full of opportunities, automation engineers are faced with multiple career choices. Mechanical engineers as an important part of it, whether the pursuit of technical depth, or aspire to cross-border expansion, its career development path is particularly broad. Let's take a deeper look at the seven development directions for automation engineers, and see which one best fits your career aspirations:

Ø Design Engineer

coversMoulds, automobiles, home appliances, construction machineryand non-standard equipment and other types of machinery and equipment in the design field.

In our daily work, we need to carry out tasks with the help of commonly used mechanical design software, such as AutoCAD, Pro/E, UG and so on. When carrying out product structure design or other related design work, repeated modifications are the norm, and you are often on the computer all day long. If you want to grow up to be an outstanding designer, you need to learn more aboutLearn about materials, techniques, processing, and aestheticsand many other aspects of knowledge.

Ø Equipment Engineer

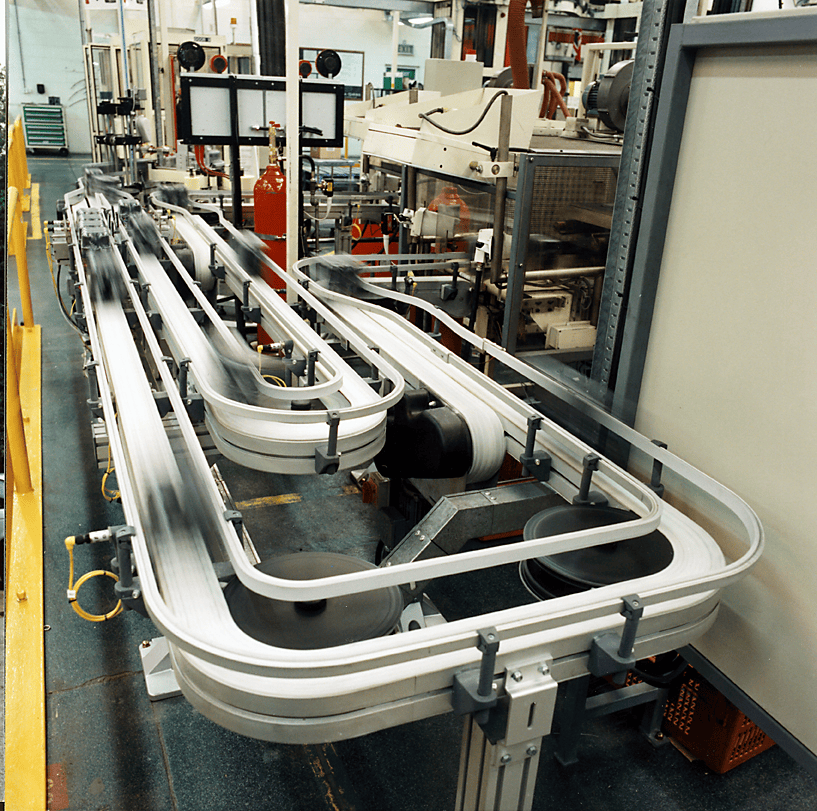

Primarily responsible for performing equipment maintenance tasks on the production floor, working with a wide variety of equipment on a daily basis.

In the event of equipment failure, repairs need to be carried out immediately; if the equipment is functioning normally, maintenance work is carried out to prevent the problem before it occurs. You must be familiar with the operating principles of the equipment under your jurisdiction, as well as all related knowledge. This is a work rhythm is very flexible position, weekdays have time for knowledge precipitation, optimisation of maintenance programmes, etc.; once encountered equipment problems, you have to quickly put into high-intensity repair work.

Ø Process Engineer

Most of the daily work scenes are concentrated in the workshop, and the main task every day is to detect the process problems in the production process in time, make detailed statistics on defective products, analyse the causes and make efforts to improve them, and make every effort to improve the production efficiency.

Preparation of process documentation and work instructions is also an important part of the job, which is slightly monotonous, but not too stressful and easy.

Ø Product Engineer

It has the key responsibility for the whole process of new model products from development to market launch.

It is necessary to study market demand, technical feasibility and many other elements, strictly control the quality of the sample, and then promote mass production to ensure that the product can be stable and efficient output. With the accumulation of experience and ability, product engineers tend to develop in the direction of project managers, whose core task is to coordinate all relevant departments within the company, and to unite everyone into a single force to complete a series of complex tasks from the start of the trial production of a new project through continuous improvement and optimisation until the final realization of mass production.

Ø machining

Most practitioners start their careers in both machine operation and programming.

If you don't want your career development to be limited to operating lathes, you can first engage in lathe operation, accumulate experience, and then study and utilise it in the direction of programming, familiarise yourself with the advantages of machine tool operation, and learn how to write efficient machining programs; or turn to the design field, and participate in product design by virtue of the practical accumulation of the understanding of the mechanical structure and machining process, and open up a new path for career development.

Ø Supplier Management Engineer (SQE)

This is also known as a purchasing position. If you are good at both technical skills and communication skills, then becoming an SQE is a good career path. In your day-to-day work, you will be required to make frequent visits to suppliers and negotiate with them, so communication skills are the most important of all the competencies required of an SQE. It is also necessary to accumulate a wealth of work experience and acquire knowledge in a variety of areas, such as mechanical expertise, production management knowledge, and business knowledge.

Ø Sales Engineer

They are mainly responsible for selling mechanical products, ranging from those who focus on developing sales channels, to those who market directly to end-users, to those who are committed to a specific industry.

It should be noted that, after choosing to do mechanical product sales, the work content will gradually pull away from the technical field, and then want to transition to engage in technical work, usually more difficult. Because the sales work focus on communication, marketing and business negotiation and other ability to train, while the technical positions require deep professional knowledge and practical skills, the two required skills and knowledge system difference is obvious.

Automation mechanical engineers will be because of different personality traits, different genders in the matching position there are differences. But no matter what the final choice of positions, continuous self-improvement is always a wise move, after all, gold will always shine, the real talent will not be buried for a long time. The most critical point is that, must be closely combined with their own actual situation to make choices, to ensure that the position fits their long-term development, not blindly follow the trend, in order to get out of a suitable path for their own advancement.