Equipment Profile

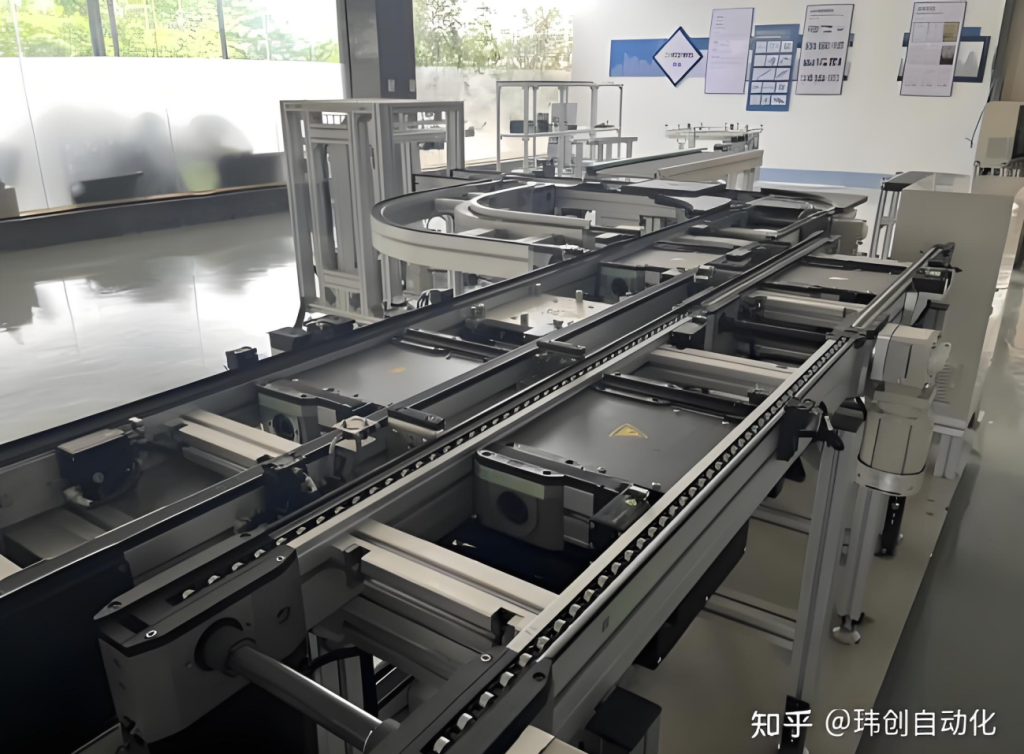

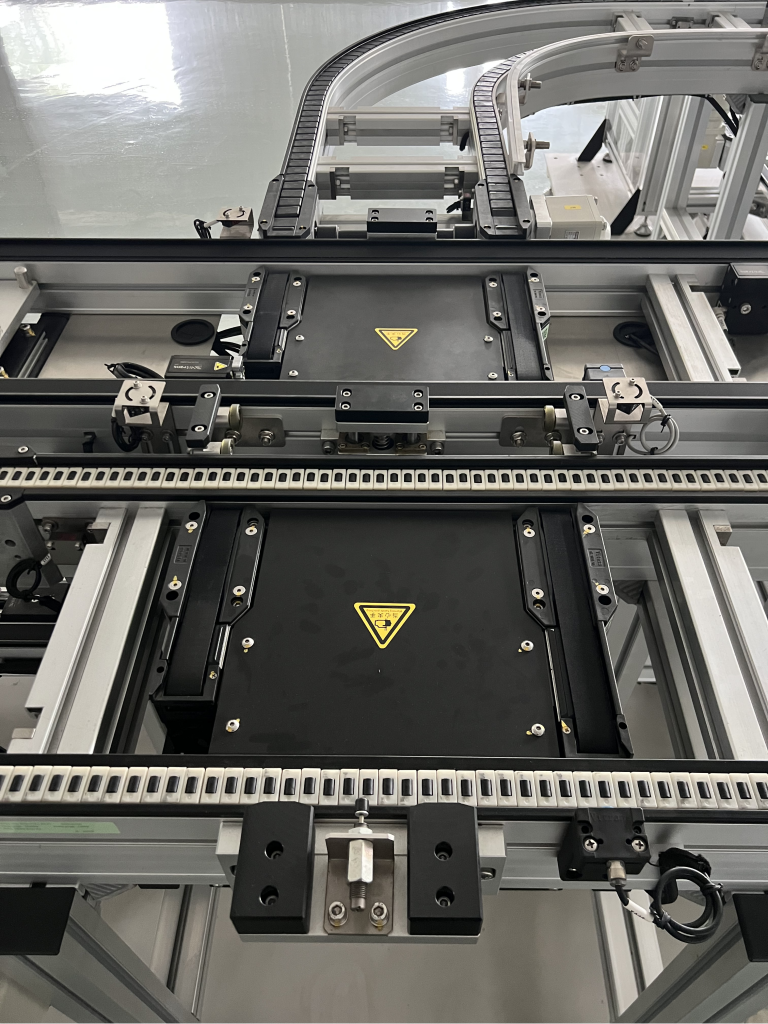

Pallet conveying systemsIt generally consists of linear conveyor sections, jacking traverses, jacking positioning, turning units (e.g. flat-top chain turns, round belt turns), jacking rotaries, hoists and conveyor control units (e.g. buffer stops). These can be combined with modular conveyor units such asFlexible chain line conveyor systemmaybeMagnetic Levitation Conveyor SystemThe system consists of a highly flexible automated conveyor line for automated flexible conveying.

Highly scalable

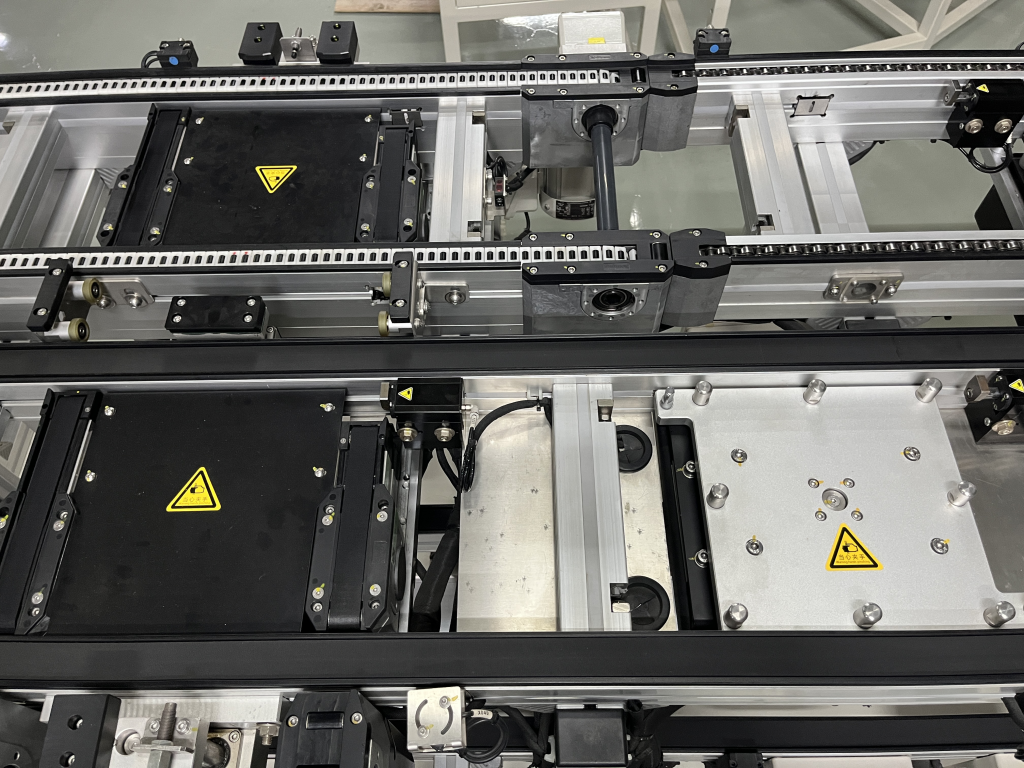

The pallet conveying system is highly scalable and can be flexibly designed according to the production requirements in terms of conveying volume, conveying speed and assembly stations, and is equipped with various auxiliary components, such as positioning pin bushings, standard pallets, jigs and fixtures, and so on. Its transmission methods include synchronous transmission (forced) and asynchronous transmission (flexible), which can be selected according to different production scenarios and configurations to accurately meet the requirements of assembly and conveyance, ensuring the efficient operation and flexible adjustment of the production line.

Success Stories

Battery assembly line - with double layerFlat Belt Conveyor Line+Worker's pallet

1. Single line 5PPM

2. Fully automated production, modular design

3. Adaptable core size: width 140~180, length 91~210, thickness 20~80

application scenario

In the production process of new energy batteries, the pallet conveyor system is used to transport battery modules from one station to another for charging, testing, packaging and other processes.

System Configuration

Flat belt conveyor line with jacking traverse and jacking rotation modules is adopted to achieve fast and accurate conveying of battery modules.

Application Advantages

Improvement of production efficiency

-Continuous conveying

-High degree of automation

Enhancing Product Quality

-High Precision Positioning

-Anti-static design

Space cost savings

-Double layer design

-Flexible layout

Reduced maintenance costs

-Modular design

-Durable

Effectiveness of implementation

By introducing a double layerFlat Belt Conveyor LineCombined with a pallet conveying system for work pallets, this battery assembly line has helped the company achieve significant improvements in production efficiency and stable product quality. At the same time, the automation of the system reduces the need for manual intervention, saves space and maintenance costs, and provides strong support for the company's sustainable development and market competitiveness.