Description

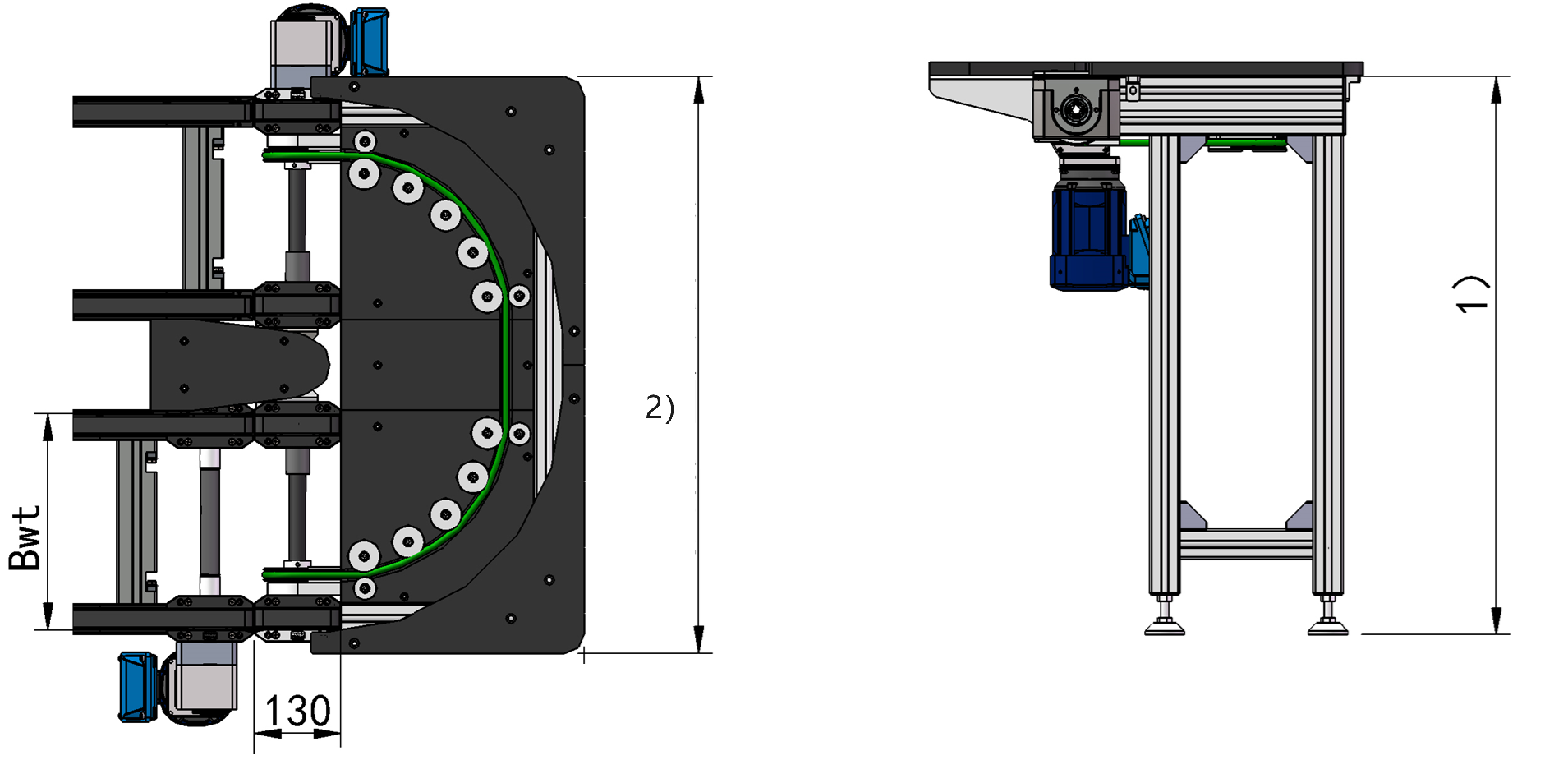

KV2/180 turning unit

- Transmission medium : Antistatic round belt

- Width of pallet in transport direction/mm : 160,240,320,400,480 (160≤Bwt≤480)

- Length of pallet in transport direction /mm : 160,240,320,400,480 (160≤Lwt≤480)

- Standard pallet size/mm: 160 x 160, 240, 320 240 x 160, 240, 320, 400 320 x 160, 240, 320, 400, 480 400 x 240, 320, 400, 480 480 x 320, 400, 480

- Maximum load/kg. 20

- Standard speed (metres per minute) . 6,9,12,15,18

- Distance between transmission lines/mm : 90, 135

- Curve Direction . CO, CL

- Motor mounting method : L, R, M

- Voltage /V : 220/380 AC

- Frequency /Hz : 50

- Motor Connection : junction box

cutting edge

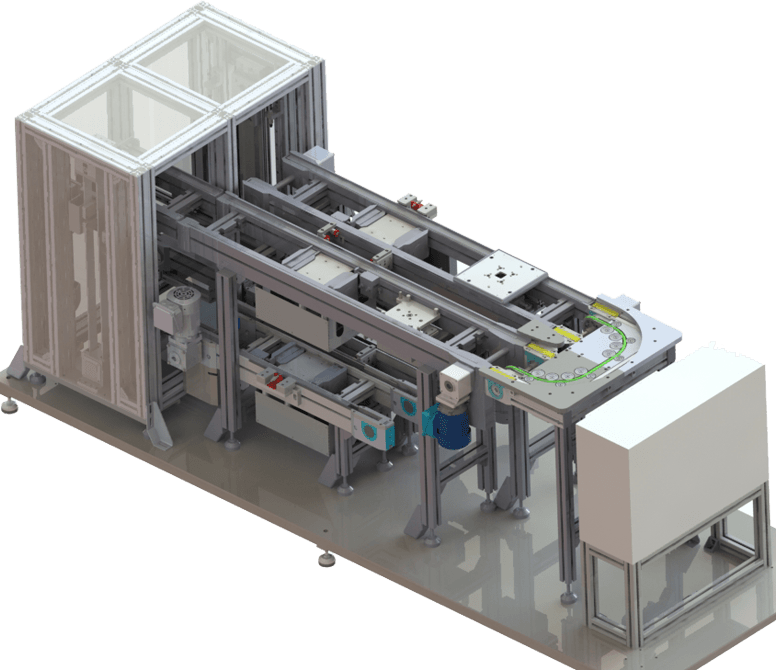

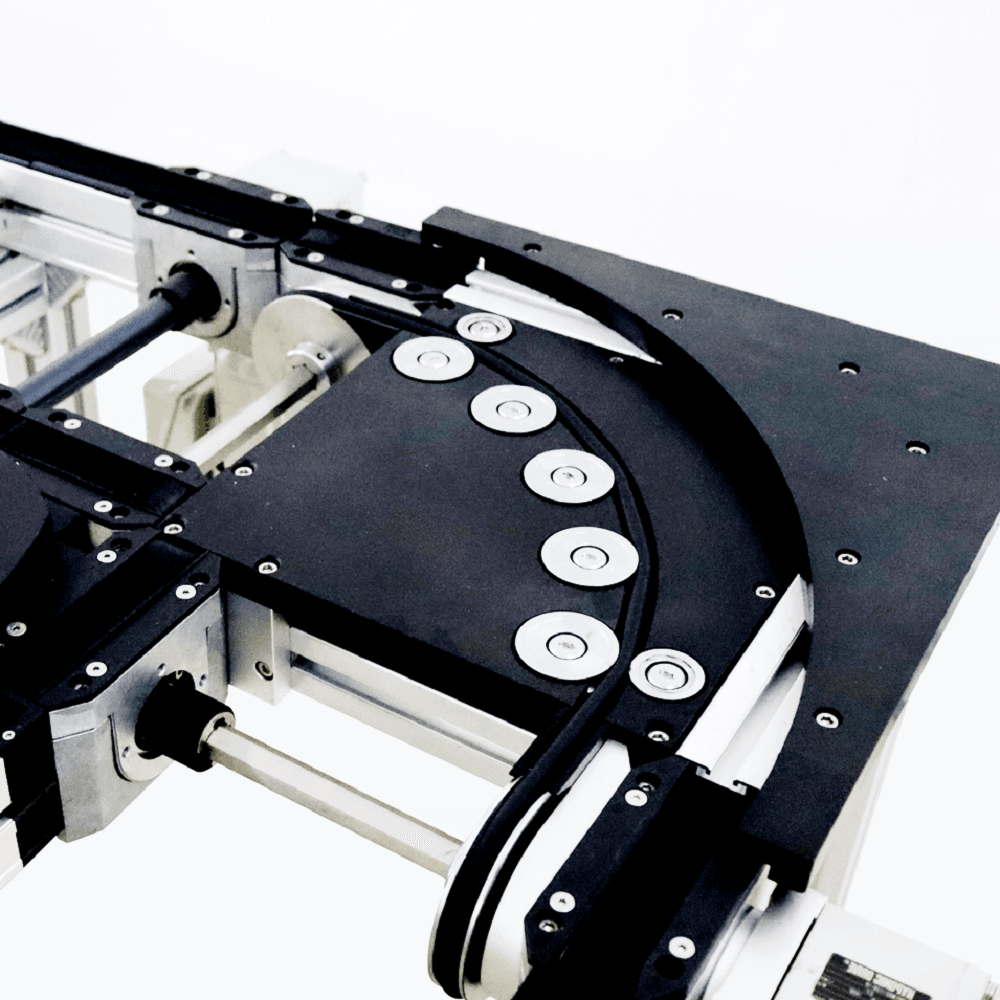

- Seamless manoeuvrability: The circular belt curves are at the heart of the production plant and their manoeuvrability changes the way pallets are turned. The smooth circular curve allows pallets to glide seamlessly, minimising friction and optimising the overall flow of material. This innovative design ensures a harmonious choreography of goods movement and increased efficiency.

- Precision in space optimisation: one of the outstanding features of round belt curves is the ability to make turns with a minimum turning radius. This space-saving advantage is particularly important in facilities where space is at a premium. A tight turning radius not only saves valuable floor space, but also opens up new possibilities for layout design, enabling manufacturers to make the most of their production areas.

- Adaptive Integration: Flexibility is a design feature of the Round Belt Curve. Its modular construction allows for easy integration into existing conveyor systems, providing manufacturers with the adaptability they need to customise their material handling processes. Whether retrofitting an assembly line or designing a new system, the Round Belt Curve adapts seamlessly to a variety of manufacturing environments.

- Gentle handling and robust performance: In addition to its elegant curves, the round belt curve excels in gentle material transport. It is therefore the first choice for transporting fragile items, from pallets to complex electronic components. The robustness of this conveyor ensures that products are transported smoothly without risk of damage, contributing to a reliable and efficient production process.

- Increased efficiency: The round belt turn is more than just a conveyor component, it is an efficiency amplifier. Its role in conveying and positioning pallets increases the overall efficiency of the material handling process. By reducing the risk of blockages and simplifying the flow of goods, this conveyor becomes an important ally in the quest for lean and efficient production.

- Operates in an environmentally friendly way: as all industries place increasing emphasis on sustainable development, the round belt curves coincide with these environmental objectives. Its efficient operation minimises energy consumption and its durable design ensures a longer service life, helping to reduce waste. In the current era of manufacturing, the round belt curve embodies an environmentally friendly conveying process.

appliance

Vitrans' competitive advantage:

fierce competition Conveying SolutionsVitrans stands out as a beacon of reliability and innovation. Compared to industry giants such as Bosch, Dorner and Flexlink, Vitrans' round belt curves are not only competitive, they are superior.The Vitrans brand has become synonymous with quality, efficiency and is committed to continuously pioneering innovations in the following areas.

The round belt curve takes centre stage in Vitrans' material handling systems, conducting a symphony of efficiency, precision and space optimisation. Its strengths in seamless operability, adaptive integration, and Vitrans' commitment to excellence make it an indispensable tool for modern manufacturers who want to take their material handling systems to new heights.