Description

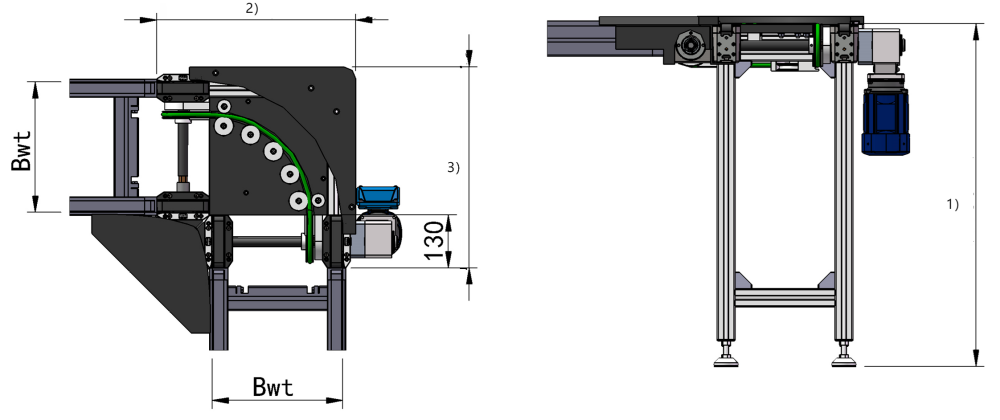

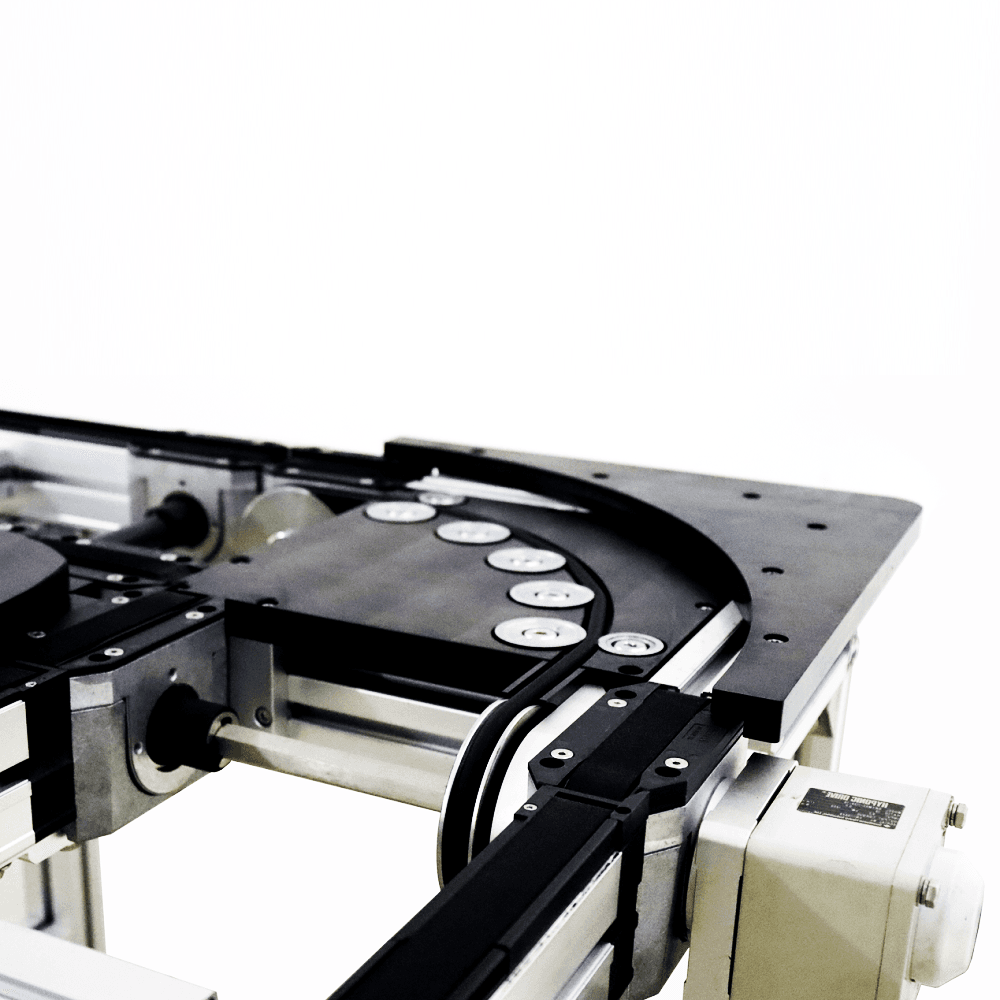

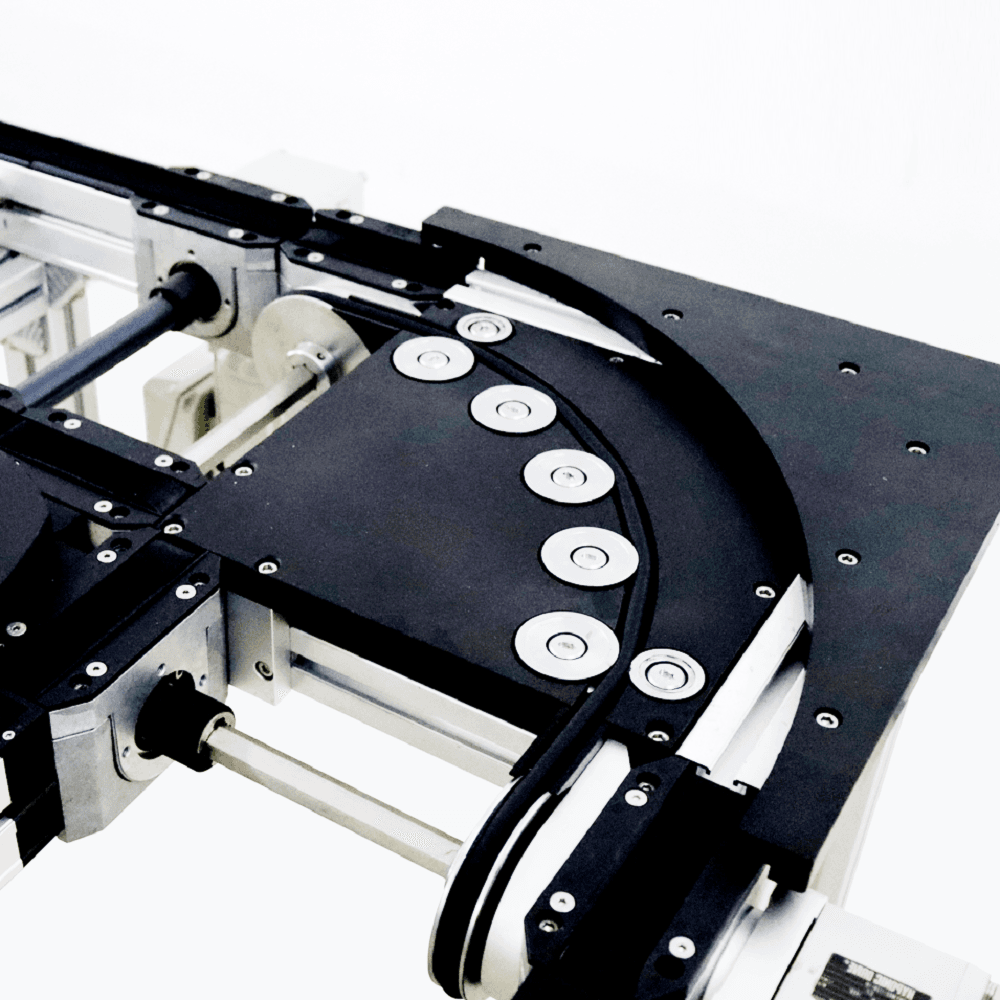

KV2/180 turning unit

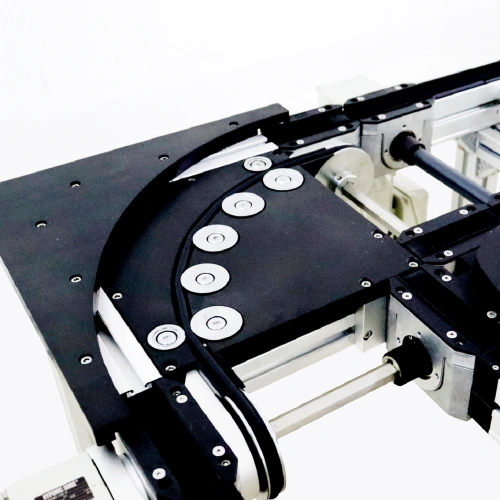

- Transmission medium : Antistatic round belt

- Width of pallet in transport direction/mm : 160,240,320,400,480 (160≤Bwt≤480)

- Length of pallet in transport direction /mm : 160,240,320,400,480 (160≤Bwt≤480)

- Standard pallet size/mm: 160 x 160, 240, 320 240 x 160, 240, 320, 400 320 x 160, 240, 320, 400, 480 400 x 240, 320, 400, 480 480 x 320, 400, 480

- Maximum load/kg. 20

- Standard speed (metres per minute) . 6,9,12,15,18

- Distance between transmission lines/mm : 90, 135

- Curve Direction . CO, CL

- Motor mounting method : L, R, M

- Voltage /V : 220/380 AC

- Frequency /Hz : 50

- Motor Connection : junction box

cutting edge

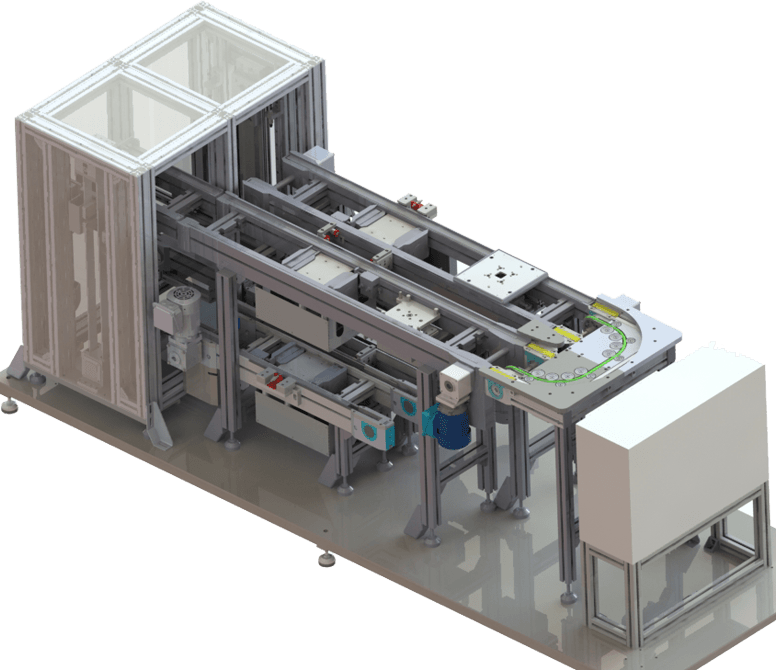

- Flexible layout: can be flexibly connected with linear conveying line, can achieve 90 degrees - 180 degrees of turning conveyor, to meet the needs of different workshop layout and process flow, effective space-saving.

- Conveying variety: can convey all kinds of bulk materials, cartons, bags and other single piece of goods of small weight, the conveyor belt material has a variety of choices such as PVC, PU, etc., to meet the oil resistance, corrosion resistance, anti-static and food-grade, and other special conveying requirements.

- Stable operation: the fan belt is equipped with special deflection rollers, which can effectively prevent the belt from deflection, ensure the stability of material conveying, and reduce the shaking and falling of materials in the conveying process.

- Lower noise: compared with some other conveyor equipment, the noise generated during operation is lower, suitable for use in places with higher requirements for noise in the working environment, such as electronics, food, pharmaceuticals and other workshops.

- Easy maintenance: relatively simple structure, easy to disassemble and replace the main components, routine maintenance and repair work is relatively easy, reducing maintenance costs and downtime

- Convenient speed adjustment: the belt running speed can usually be flexibly adjusted according to the actual production demand, and can match the production rhythm of upstream and downstream equipment.

- Strong compatibility: It can be seamlessly connected with a variety of automated equipment and production lines, such as robots, assembly machines, testing equipment, etc., to form a complete automated production system.

appliance

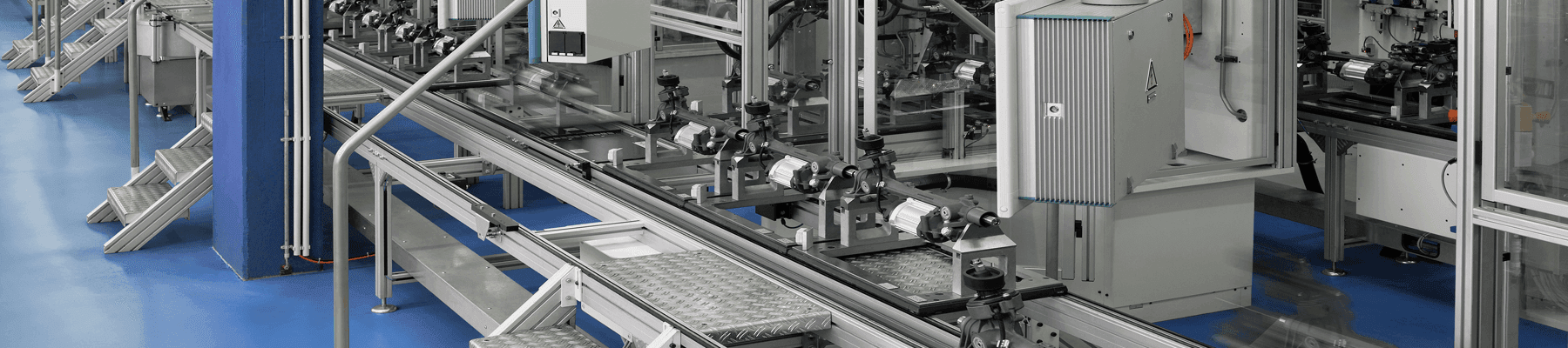

Vitrans: setting new standards

In a highly competitive market, Vitrans sets new standards for quality and reliability. In competition with industry giants such as Bosch, Dorner and Flexlink, Vitrans is not only at the top of the heap, it's also on the rise. The round belt curves adorned with the Vitrans logo have redefined what is expected of it.