Description

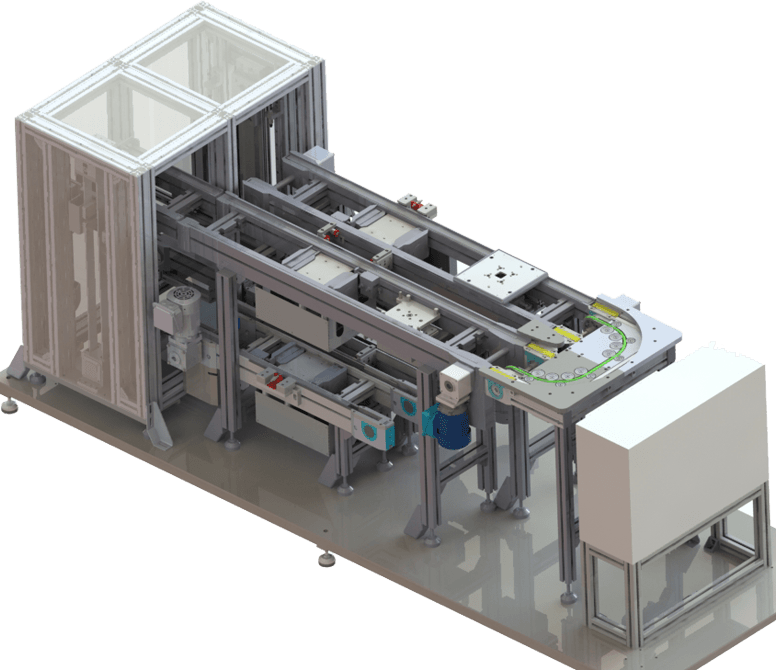

AC2 Speed Chain Conveyor Line

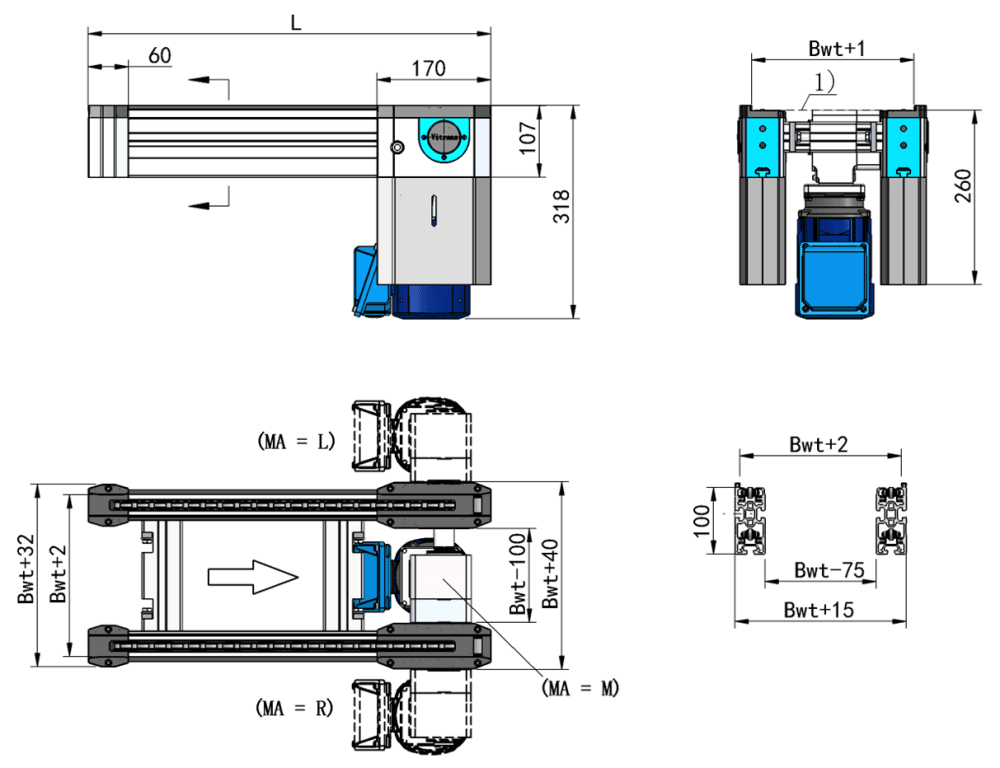

- Conveying medium : Stacked roller chains

- Width of pallet in transport direction/Mm. 160, 240, 320, 400, 480, 640, 800 (160≤Bwt≤800)

- Conveyor length /Mm : 300≤L≤6000

- Nominal speed (m/min). 6, 9, 12, 15, 18

- Maximum load/kg. 700

- Driving method : Three-phase motors

- Motor mounting method : L, R, M

- 电机安装方向 : 0°, 90°, 180°, 270°

- Voltage/V. 220/380 AC

- Frequency /Hz : 50

- Motor Connection : junction box

Key Benefits

- Smooth, precise palletised transport

- Durable chain design for heavy duty use

- Modular design for easy integration

- Adaptable to various pallet types

- energy-saving and environmentally friendly

autoharmony

At the heart of the revolution, roller chain conveyor lines resonate with the essence of automated harmony. Their precision design allows for smooth, synchronised material transfer with conveyors such as pallet conveyor systems. From the assembly line to the production floor, the automated precision of these conveyor lines serves as a catalyst for increased productivity.

Continuous innovation in technology

Roller chain conveyor lines are the result of innovative chain technology that transcends the traditional boundaries of material handling. The robust chain design ensures the longevity of the conveyor line, making it ideal for heavy-duty industrial applications. This innovation is also reflected in the modular nature of the conveyor line, which allows for easy integration with a variety of pallet systems, minimising downtime.

Environmental Treatment Solutions

In addition to industrial environments, multiplier chain conveyor lines have a place in environmentally friendly conveying solutions. Their energy-efficient operation and minimal impact on the environment make them ideal for sustainable practices. Whether transporting batteries or pallets, these conveyor lines comply with highly responsible and eco-conscious material handling concepts.

Future-proof conveyor systems

Roller chain conveyor lines have transcended their role as mere conveyor lines to become a future-proof material handling workhorse. From handling pallets in industrial systems to enabling convenient conveying, their adaptability and reliability make them an indispensable element of future conveyor systems.

Efficiency in motion

In the industrial process of production line conveyor lines, the multiplier chain conveyor line is the epitome of movement and efficiency. Its smooth and reliable conveying mechanism ensures a continuous flow of pallets, helping to optimise the entire production process. The versatility of this conveyor line is further enhanced by its ability to carry a wide range of pallet types, including plastic pallets and roller chain pallets.

Release design

The Speed Chain conveyor line sets a new paradigm in design aesthetics, blending form and function. Its modular and adaptable design not only ensures easy integration into existing conveyor systems, but also allows rapid customisation to specific production requirements. The result is an enhanced visual appeal that complements the efficiency of the conveyor line.

vitrans

vitrans

vitrans

Belt Conveyor

- Accumulated

- modular

- Positioning Accuracy:0.1mm

- Maximum load up to 250kg

- Speed 18m/min OR Faster

- Size: up to 6m/L,up to 6m/W

vitrans

vitrans

vitrans

Roller Chain Pallet Conveyor

- Accumulated

- modular

- Positioning Accuracy:0.1mm

- Maximum load up to 2200kg

- Speed 18m/min OR Faster

- Size: up to 6m/L,up to 6m/W

vitrans

vitrans

Attachment Conveyor

- Accumulated

- modular

- Positioning Accuracy:0.1mm

- Maximum load up to 250kg

- Speed 18m/min OR Faster

- Size: up to 6m/L,up to 6m/W

vitrans

vitrans

vitrans

Flexible (Vario Flow) Chain Conveyor

- Accumulated

- modular

- Positioning Accuracy:0.1mm

- Maximum load up to 2200kg

- Speed 18m/min OR Faster

- Size: Unlimited