Description

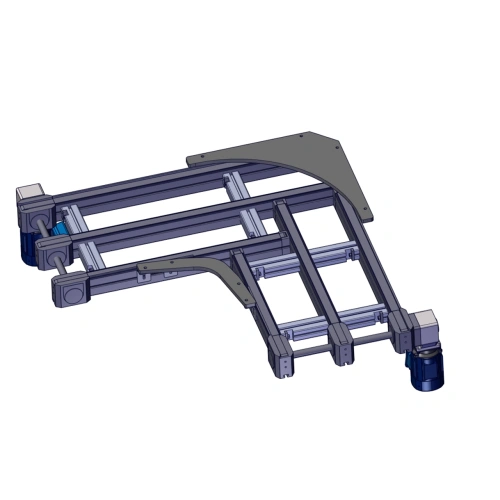

QV forced turn design

QV Forced Turn

- Transmission medium : toothed belt

- Direction of transport. Conveyor pallets can be turned 90° clockwise (anti-clockwise).

- Transfer direction tray width /mm: 160 mm to 640 mm

- Length of pallet in the transfer direction /mm : 160 mm to 640 mm

- Curve length /mm : customisation

- Driving method : Three-phase motors (2)

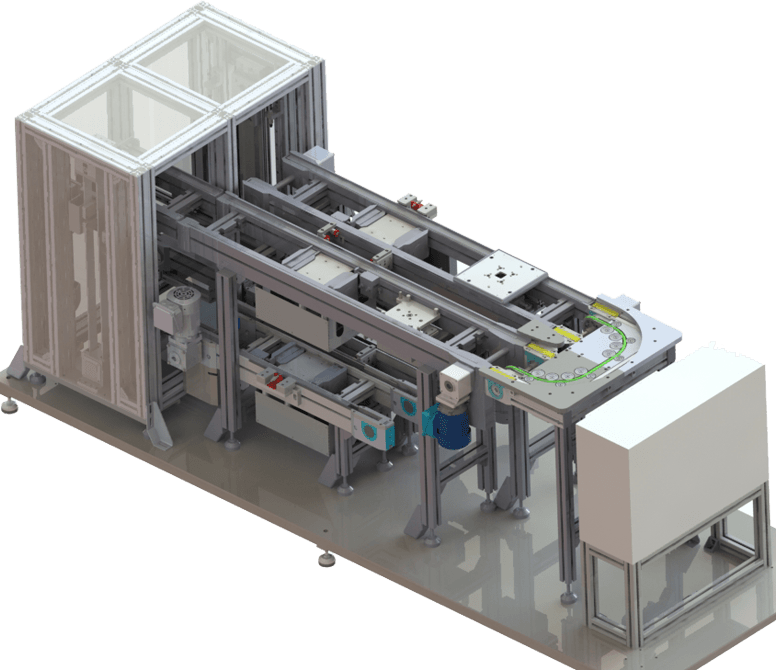

mileage

- precise synchronisation

- High precision processing

- Reduced maintenance

- Quiet operation

- Modular and customisable

- smooth transition

appliance

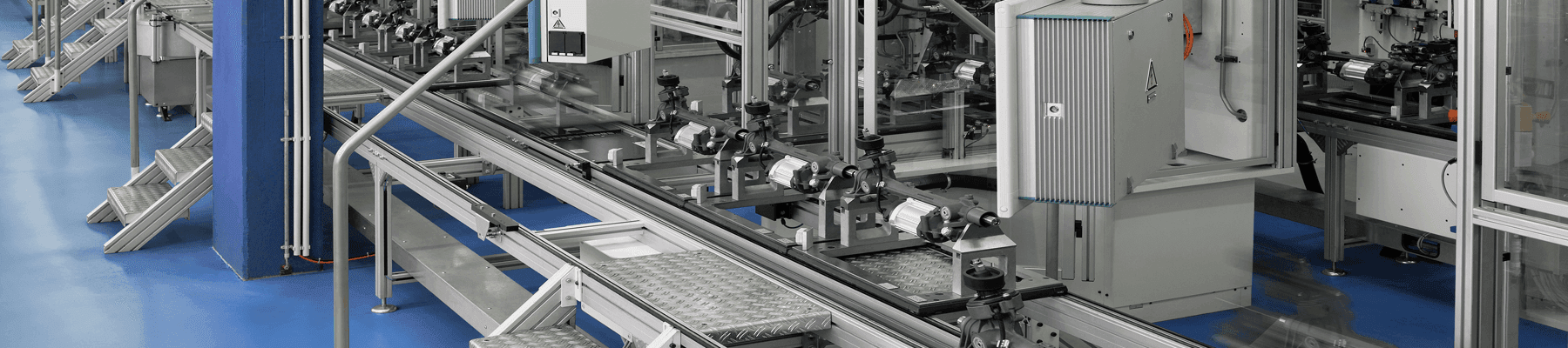

QV Forced Turns: Precision conveying in palletised conveyor systems

QV forced turns and round belt turns are both Pallet conveying systems Designed for travelling around curves or bends. The main differences are the power transmission method and the applicable pallet size and load range.

The round belt turn relies on a single round belt to provide the turning power for the pallet. However, it has a limited capacity and can only be used for pallets less than 400mm in size with a maximum load of 20kg.

On the other hand, the QV forced turn utilises six timing belts and two motors to generate the turning force. This design provides a more powerful power source, allowing it to accommodate a wider range of pallet sizes, ranging from 160 mm to 640 mm. In addition, it can handle heavier loads compared to round belt turning.

In summary, whilst both types of turn are used to drive pallets for rotation, timing belt turn conveying offers a more powerful and versatile solution for a wider range of pallet sizes and higher load weights than round belt turns.