Conveying assembly line is a general term for assembly line equipment applied to material and product conveying in production. Conveying line in modern industrial production plays an important role in food, electronic products packaging, motor, home appliance assembly, photovoltaic, lighting, automotive manufacturing and other industries have a wide range of applications.

In the process of industrial production, the application of various types of conveyor systems are varied, do you know what? Today to do a brief introduction.

-Common Conveyor Line Types -

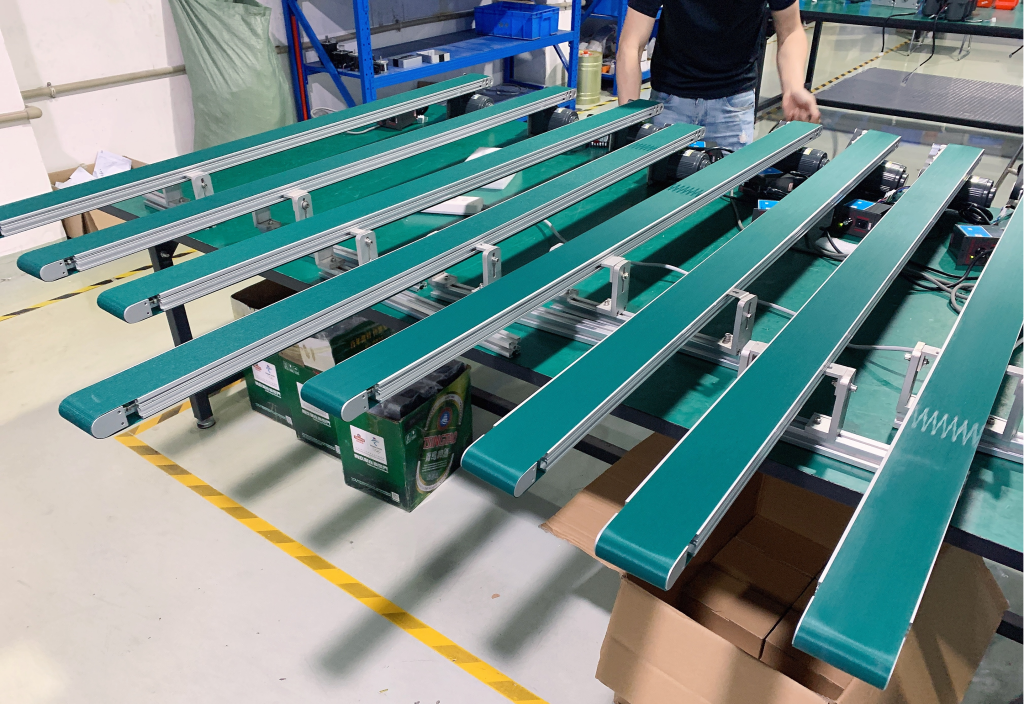

01

specificities::Simple structure, smooth conveying, easy to install and maintain.

Applications:It can convey all kinds of bulk materials, as well as all kinds of small parts, bags and other products with light weight.

02

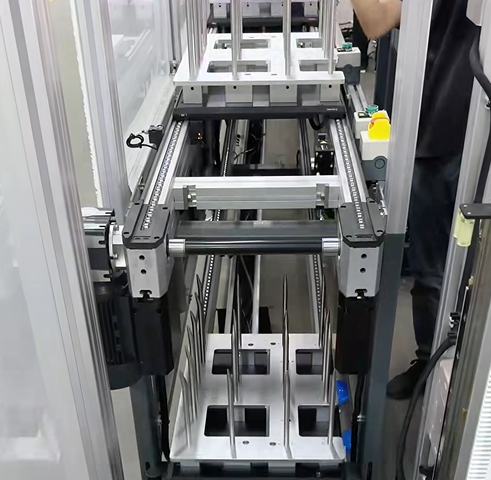

Synchronous belt conveyor line >>

specificities::High precision synchronous drive with workpiece pallet, modular design for easy maintenance and expansion, low noise operation.

Applications:Mostly used in new energy battery cell assembly, automotive electronics assembly, and general automated production lines.

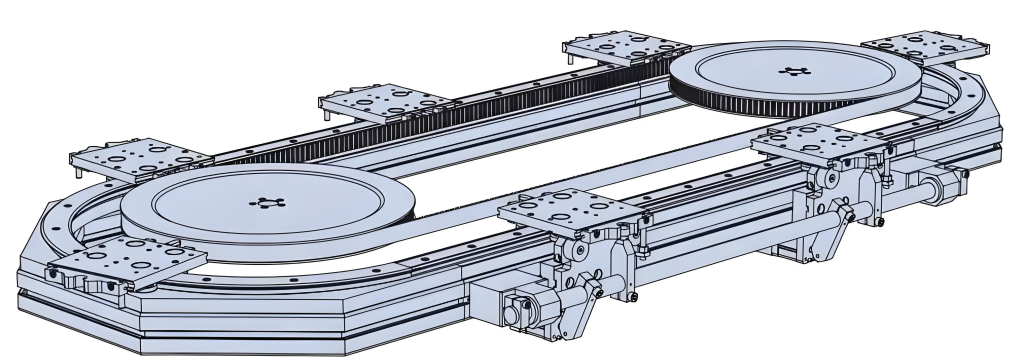

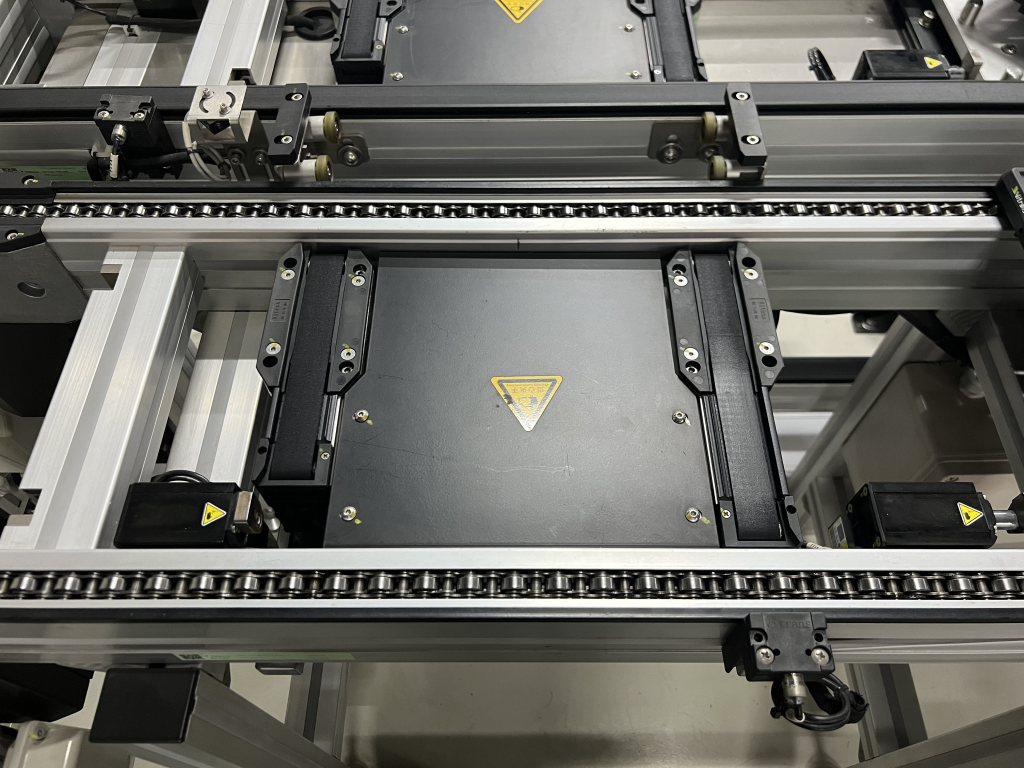

03

specificities::Generally used with work pallet, stable and long-lasting, large conveying capacity, strong load-bearing capacity, suitable for the continuous production of large quantities of products.

Scope of application: Widely used in various electronic and electrical appliances, electromechanical, new energy, photovoltaic, lighting and other industry production lines.

04

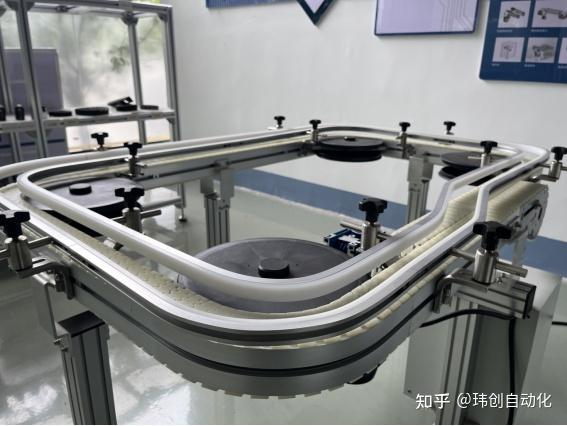

Flexible chain conveyor line >>

specificities::The conveying surface is flat and smooth, with low friction; the layout is flexible, and horizontal, inclined and turning conveying can be completed on one conveying line.

Scope of applicationIt is suitable for conveying all kinds of glass bottles, PET bottles, cans and other materials, and can also convey all kinds of bags. And because of the flexible layout is suitable for the scenes with more space limitations.

05

specificities::Large conveying capacity, strong carrying capacity, smooth running and low noise.

Applications:It is suitable for the conveyance of the articles whose bottom is flat, such as the conveyance of all kinds of boxes, bags, trays, etc. Bulk materials, small articles or irregular articles need to be put on the pallet or in the turnover box for conveyance.

06

Heavy Duty Accumulation Roller Line >>

specificities::Strong load-bearing capacity for accumulation, forward and reverse rotation and stacking operation of pallets, stable power transmission and high operating efficiency.

Applications:It is suitable for the assembly and conveyance of heavy parts such as engines and gearboxes in the automotive manufacturing industry, and is also commonly used in logistics warehousing and sorting centres, and in the integration of automated production lines.

For the introduction of automated conveyor systems for specific factory production scenarios, it is necessary to analyse specific issues according to the actual, specific problems. A variety of conveyor line types described above, each with its own advantages and disadvantages, the design must first clarify the actual needs, and then consider how to choose a cost-effective, ideal conveyor mode.