I. Automobile manufacturing industry

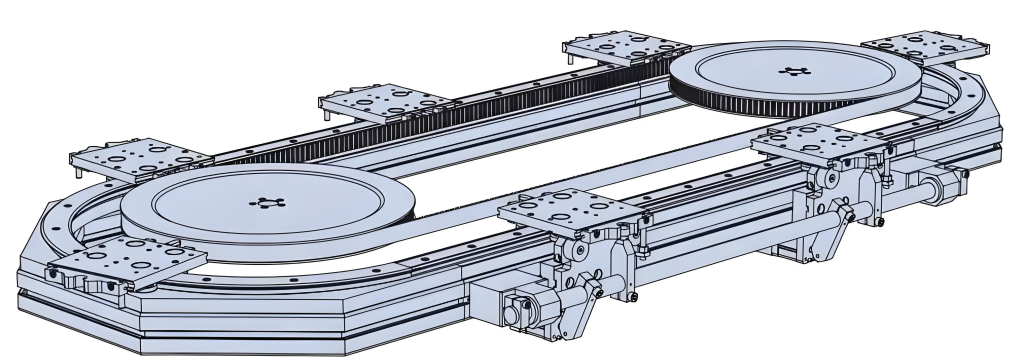

1,Assembly Line Material Dispatch

It is used for conveying large parts such as engines and seats, which can be flexibly suspended between assembly stations through the accumulating function, so as to adapt to the difference in the tempo of different work processes. For example, it can accurately position the bodywork when assembling (error ±0.5mm), avoiding scratches caused by manual handling.

- Paint shop buffer conveyor

High-temperature-resistant rollers convey the car body in the transition between electrophoresis and drying processes, temporarily store semi-finished products in the accumulation area, and balance the spraying and drying beats, while the dust-proof design guarantees a clean paint surface.

3,Paint shop buffer conveyor

High-temperature-resistant rollers convey the car body in the transition between electrophoresis and drying processes, temporarily store semi-finished products in the accumulation area, and balance the spraying and drying beats, while the dust-proof design guarantees a clean paint surface.

- II. New energy battery production

- 1、Battery module assembly line

- The 300KG accumulating roller line conveys battery cases, buffers and stacks them between welding and encapsulation stations, and completes automated assembly with robotic arms, increasing the daily capacity of a single line by 40%.

- 2、PACK test line temporary storage

- The roller line accumulates fully loaded battery boxes in front of the charge/discharge test station to ensure that each unit stays for a specified period of time to complete the performance test, avoiding congestion on the production line.

- III. Logistics Sorting Centre

- 1, express parcel dynamic sorting

- Linked to the scanning system, the accumulation roller line holds parcels in front of the crossbelt sorter and automatically diverts them according to their destination, reducing the risk of overloading the system during peak periods

- 2, e-commerce warehouse intelligent caching

- Connecting AGVs and three-dimensional shelves, the roller accumulation area serves as a temporary storage place for order parcels, optimising the picking path and improving delivery efficiency by 30%.

- IV. 3C electronic assembly

- 1、Precision conveying of mobile phone screens

- The anti-static roller line is equipped with visual positioning, which accumulates the screen to the laminating station with ±0.05mm precision to avoid off-set damage and increase the yield rate.

- 2、PCB board test flow

- Setting up a jogging accumulation line between SMT placement and AOI inspection stations to balance the difference in equipment beats and reduce downtime waiting time.

- V. Appliance production lines

- 1、Refrigerator door body close box assembly

- Heavy-duty accumulation line conveys the box to the closing station, dynamic pause for robotic arm to grab the door body for precise installation, support multi-model mixed line production.

- 2. Air-conditioning outboard spraying articulation

- The oil-resistant drum line accumulates the housing of the outboard machine between the cleaning and powder coating processes, adapting to the difference in processing time of different models.