-Flexibility for unlimited production possibilities-

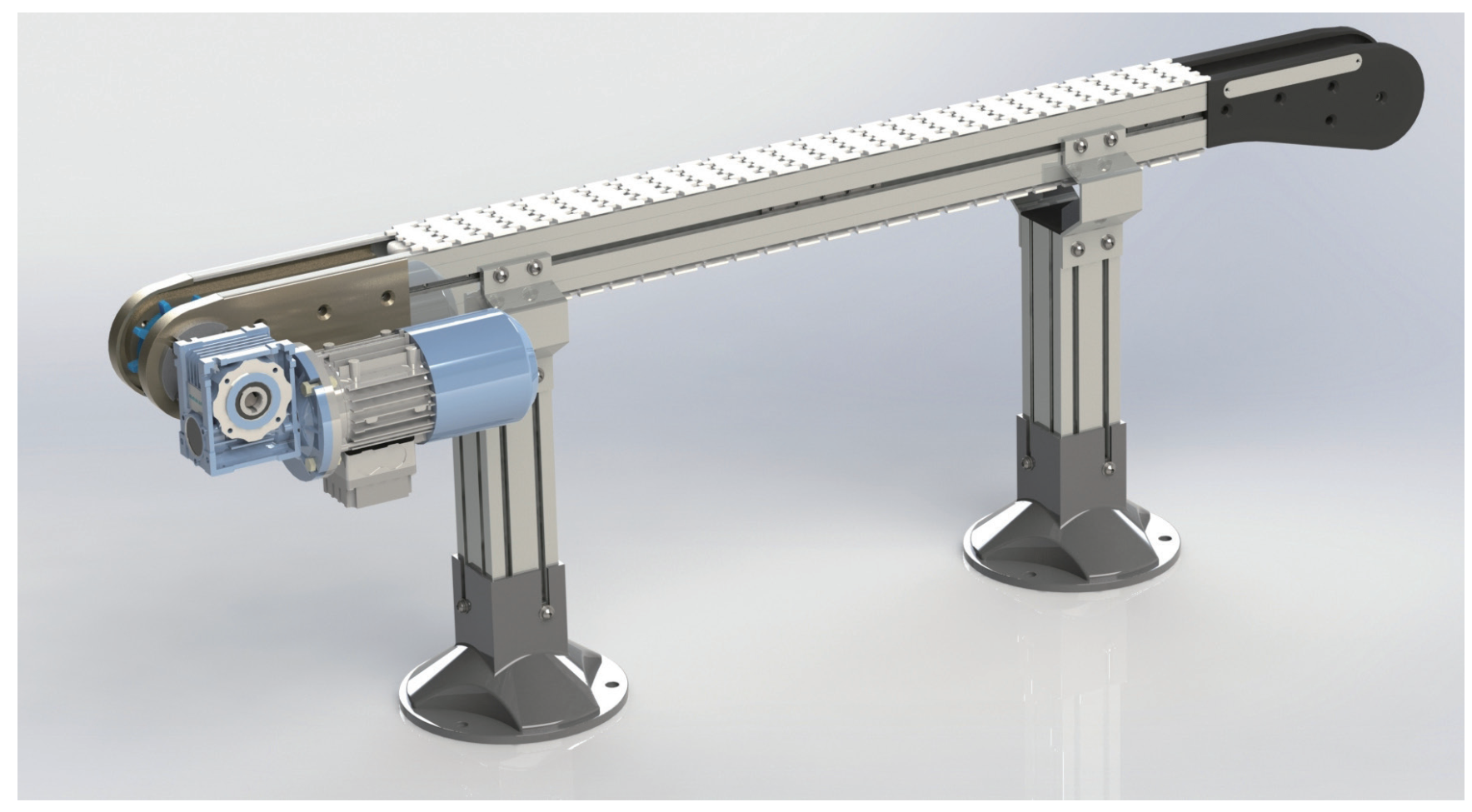

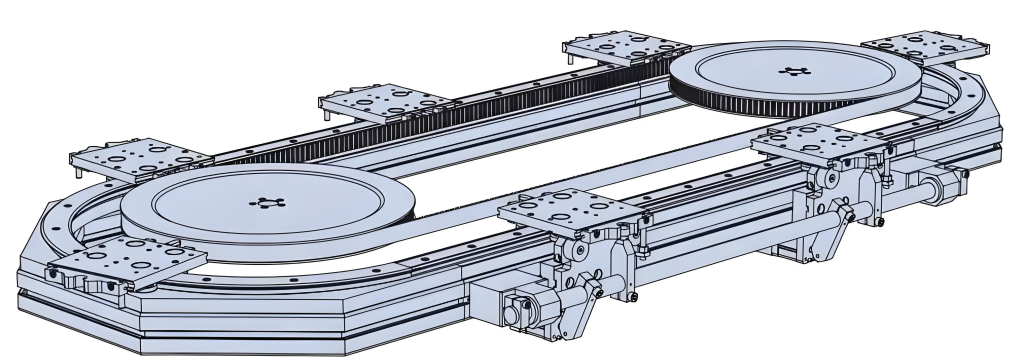

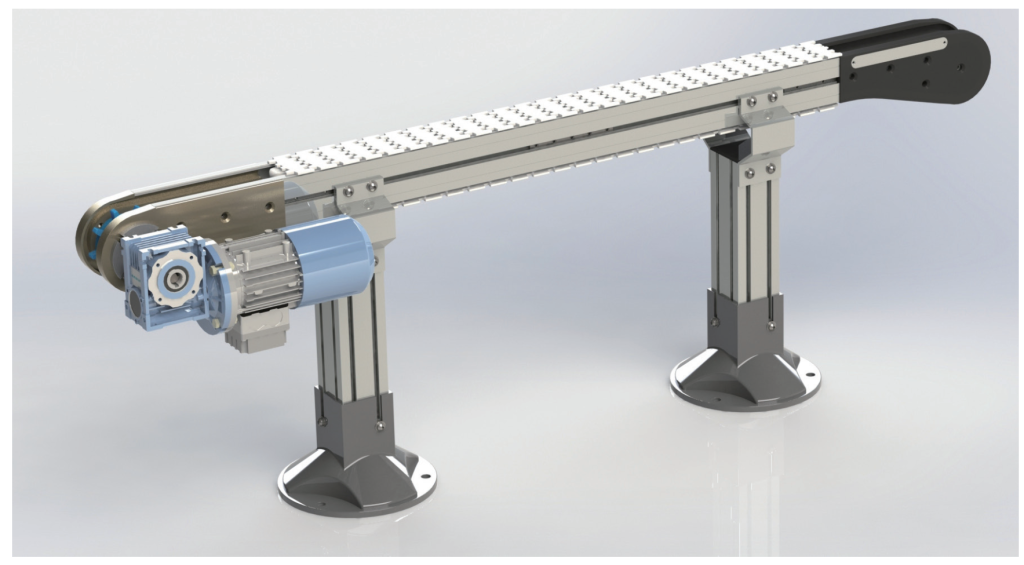

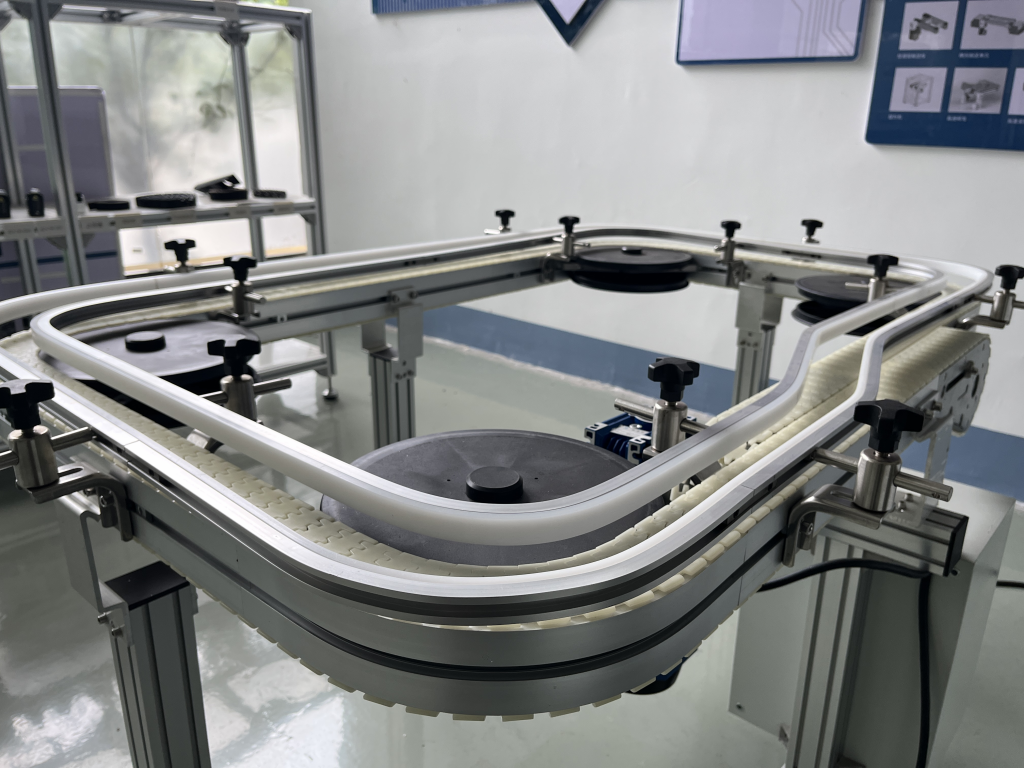

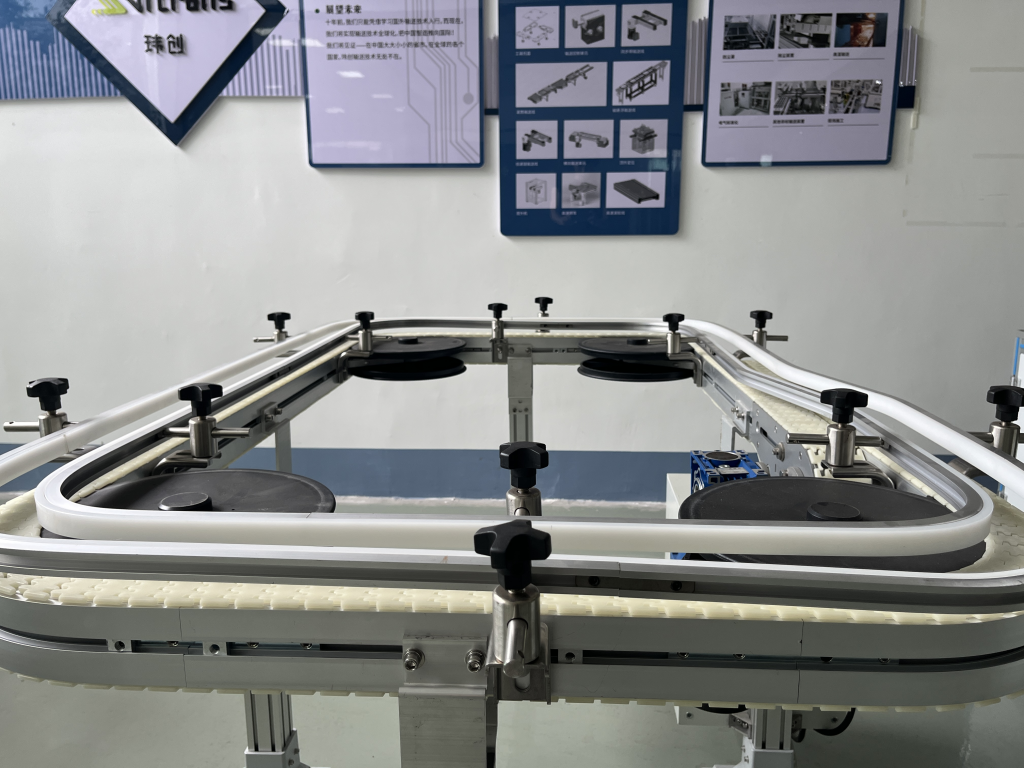

From standardisation to individualisation, from fixed lines to dynamic reorganisation, flexible chain conveyors are redefining the boundaries of industrial conveying.

Therefore, when choosing the flexible chain plate line, we need to pay attention to the following points to ensure that the most suitable product is selected:

I. Define the demand for use

1.Characteristics of conveyed items:

Understand the weight, size, shape and characteristics of the items to be conveyed, such as whether they are fragile or liquid, in order to select the appropriate material, width and strength of the chain plate.

2.Work environment:

Consider the temperature range, humidity, and cleanliness requirements of the working environment to ensure that the selected flexible chain link line can adapt to these conditions.

3.Spatial layout:

Depending on the space size and layout of the production hall, suitable conveyor lengths, turning radii and modular components are selected for a flexible layout.

4.Degree of automation:

Determine the need for integrated automation controls, such as pneumatic, electric or motorised auto-controls, to enhance productivity.

Second, focus on product performance

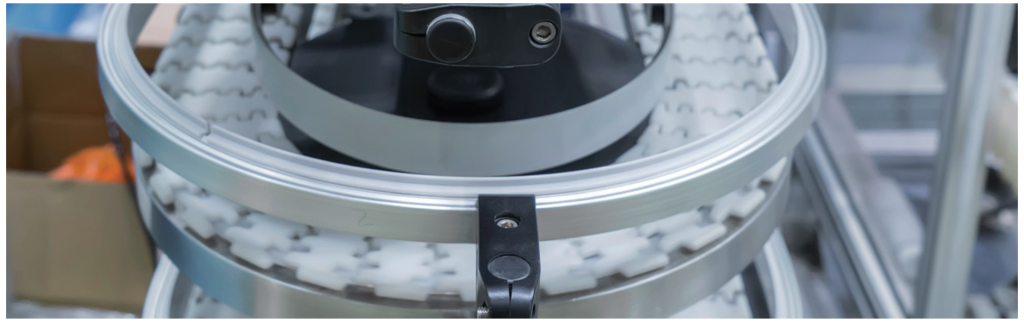

1.Cleanliness:

For food, pharmaceutical and cosmetic industries, it is necessary to ensure that the flexible chain plate line meets GMP specifications, with clean, non-corrosive and non-rusting materials.

2. Interference with the environment::

Choose products with low noise and good quieting effect to reduce the disturbance to the working environment and personnel.

3.Stability and reliability:

Ensure that the selected flexible chain line has a stable mechanical structure that prevents the product being conveyed from tipping or slipping.

4.Maintenance costs:

Consider the ease of maintenance of the product, such as modular design for easy disassembly and replacement of components, reducing maintenance time and cost.

III. Selection of suppliers and services

1.Supplier reputation:

Choose suppliers with good reputation and word-of-mouth to ensure product quality and after-sales service.

2.Technical Support:

Confirm whether the supplier can provide the necessary technical support and training to help customers better use and maintain the flexible chain link line.

3.Delivery period:

According to the project time node, select the supplier with suitable delivery date to avoid affecting the production schedule due to delivery delay.

4.After-sales service:

Understand the supplier's after-sales service policy, including warranty period, maintenance response time, etc., to ensure timely and effective support during use.

IV. Comprehensive assessment and selection

1.Compare and contrast the different programmes:

Based on the above points, compare the solutions offered by different suppliers, including product performance, price, delivery time and after-sales service.

2.Field trips:

If conditions permit, you can visit the supplier's production base and success stories to get a more intuitive understanding of product quality and service level.

3.Signing of contracts:

After a comprehensive evaluation, a formal contract is signed with the selected supplier, specifying the terms of product specifications, quantity, price, delivery period and after-sales service.

To sum up, through the steps of clarifying the usage requirements, focusing on the product performance, choosing the right suppliers and services as well as comprehensive evaluation and selection, we will be able to buy the most suitable flexible chain plate line.