In the factory floor, a simple but not simple conveyor line is quietly changing the production mode, it is the speed chain conveyor line. Compared with the traditional production line, it is better in the end? Today, through the following points of analysis to understand in depth:

01

▷ structural design

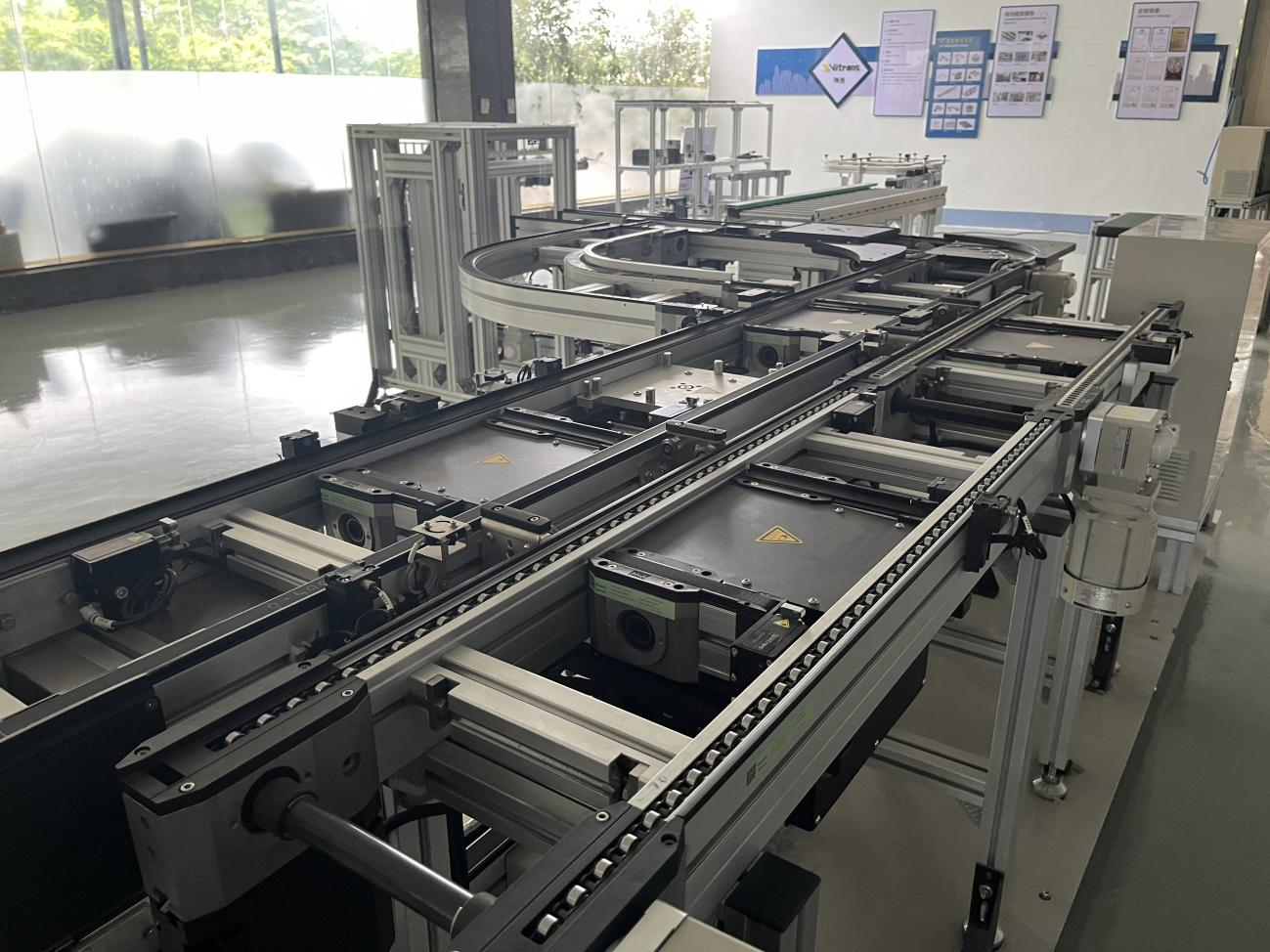

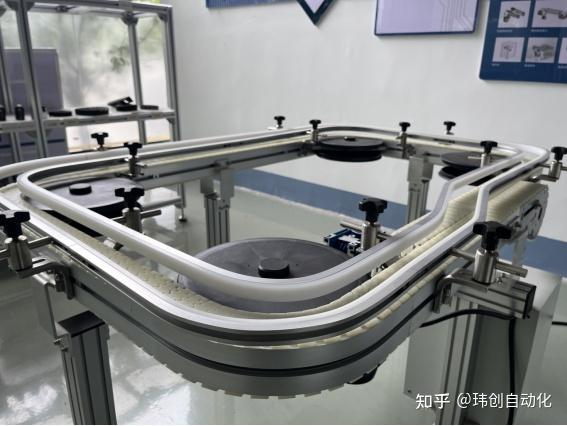

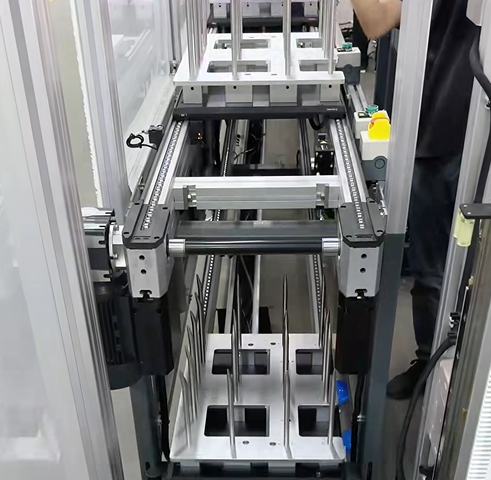

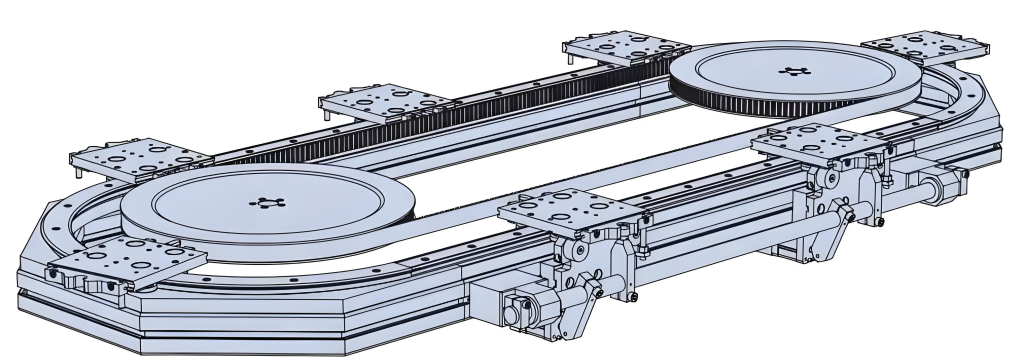

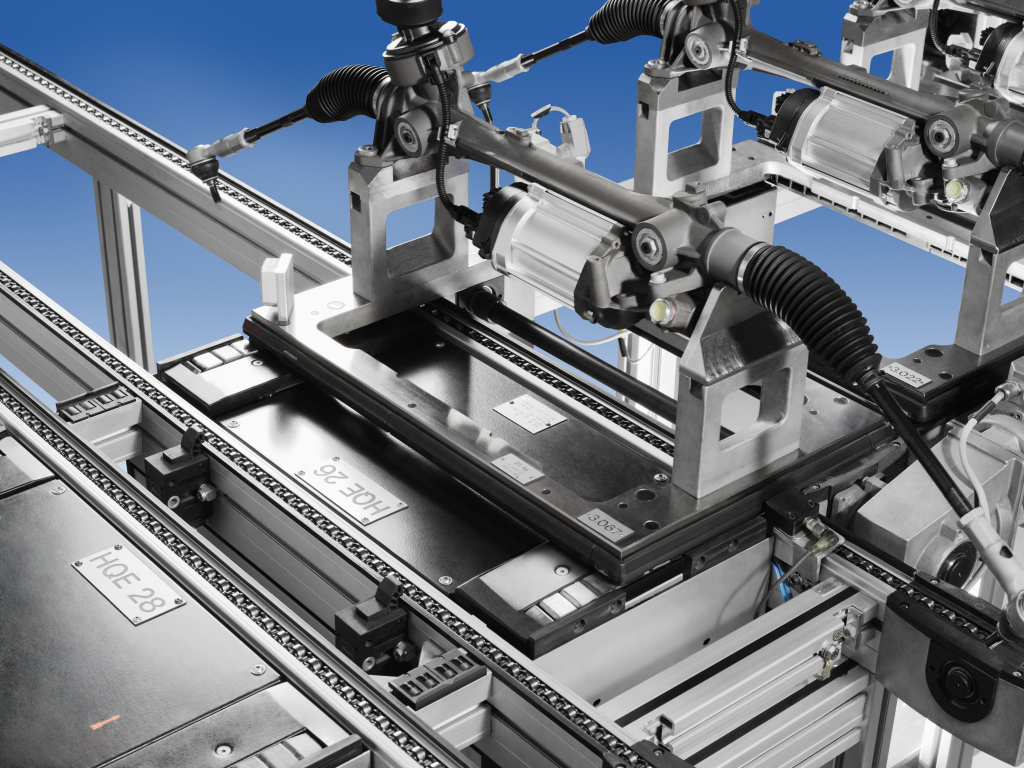

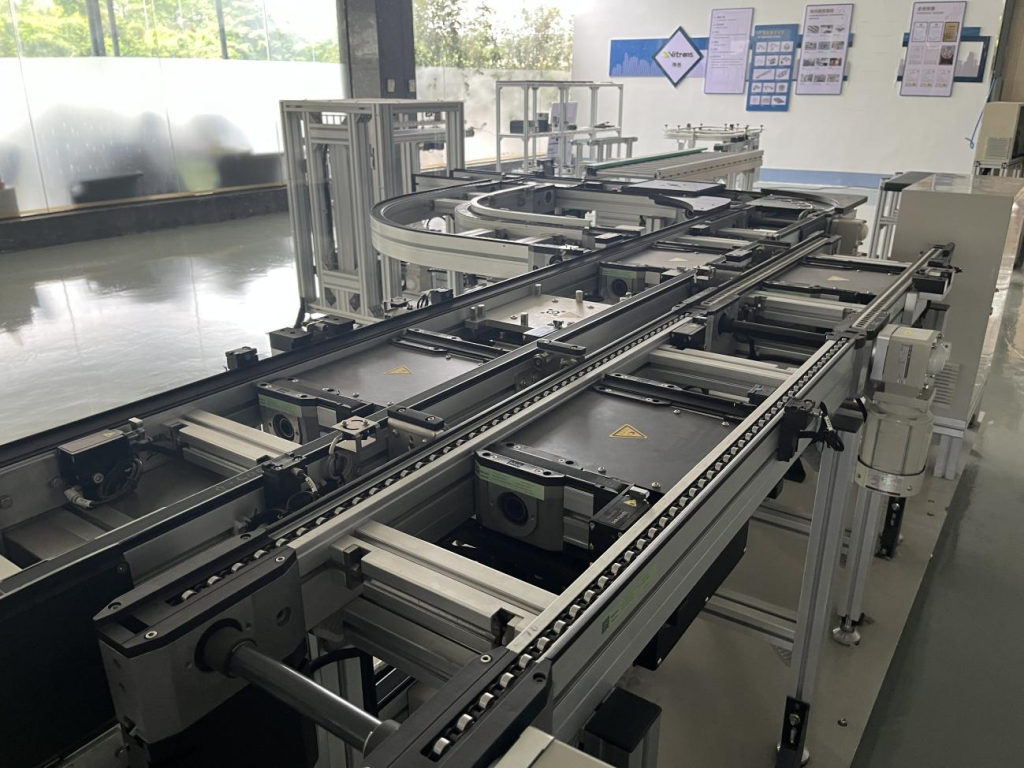

- Speed Chain Conveyor LineIt mainly consists of chain, driving device, guide rail and work plate. The rollers on the chain are like small wheels, and the work plate can slide when it is put on it, so that the material can move forward at a specific speed, which is suitable for continuous operation.

- Traditional production lines, like belt and roller conveying, feed materials by friction or rotation and have relatively simple structures.

02

▷ conveying efficiency

- Speed Chain Conveyor LineThe speed can be flexibly adjusted, the beat can be as fast or as slow as you want it to be, and multiple products can be transported at the same time, making it suitable for complex assemblies.

- The traditional production line is slow and troublesome to adjust. When encountering different products, it is often necessary to change the equipment or re-layout, which greatly reduces the efficiency. If the transport of large, heavy objects, the traditional line has to add special equipment or manual handling, the cost goes up.

03

▷ Flexibility and adaptability

- Speed Chain Conveyor LineVarious layouts, straight line, turning, climbing can be realised, and the layout can be quickly adjusted when the process changes. And as long as you change the work plate and adjust the speed, you can produce products of different sizes and shapes.

- Traditional production line layout is fixed, the product change, may be the entire line have to be modified, and costly and time-consuming.

04

▷ Automation and Intelligence

- Speed Chain Conveyor LineIt can be easily paired with robots and sensors to automate production. With the intelligent system, it can also accurately control the speed, monitor data and detect faults in advance.

- Traditional production line, the degree of automation is low, difficult to add equipment, control is also simple, out of the problem is difficult to deal with in time.

05

▷ Reliability andsafeguard

- Speed Chain Conveyor LineThe material used is good and advanced, the chain is wear-resistant and anti-manufacturing, not easy to break. The main thing is to regularly check the chain tension, lubrication, replacement of wearing parts, etc., low maintenance cost.

- The parts on the traditional production line are easy to wear and often need to be repaired and replaced, which is not only costly, but also prone to production delays.

Overall.Speed Chain Conveyor LineWith obvious advantages in efficiency, flexibility, automation and maintenance costs, it is becoming a competent helper for efficient production in factories, helping enterprises to compete in the market with more confidence.