Hey, are you worried about the production line noise and high maintenance cost? Or do you want to upgrade your equipment but are afraid of overspending? Don't worry! Today we will disassemble this set ofSave money, be as quiet as a fly, and whore out design solutionsThe flexible chain conveyor line of the newbie can get started immediately after seeing it!

I. Basic Literacy: What makes this thing cheap and quiet?

Core question 1: Will low-cost chainplates cut corners?

Rest assured that the really cost-effective chainplates play theWholesale scale + modular designFor example, the wholesale price of 63mm wide chainplates from Shanghai Kepui is just For example, the wholesale price of 63mm wide chain plate from Shanghai Koppel is justFrom $5/m, 40% below retail! Here's the secret:

- Material cost savingsHigh-strength POM engineering plastics (that is, the same material as car gears), lighter than stainless steel 70%, raw material costs down 50%.

- Structures save labour: Modular design like putting together Lego, single person 30 seconds to install a section, the installation fee than the traditional line to save 80%

- Silent Black Technology: Adding nylon noise reduction pads at the bite of the chain plate, and measuring the running noise.<30 dB--What's that? Less than the sound of a library turning the pages of a book!

The original words of the boss of an electronic factory in Zhejiang: "Changed the wholesale chain plate line, maintenance workers from 3 to 1 person, the light of the labour cost of a year to save 120,000!"

Core Question 2: Is free design a ruse?

Don't believe the lip service! The real free programme has to be seen in these three ways::

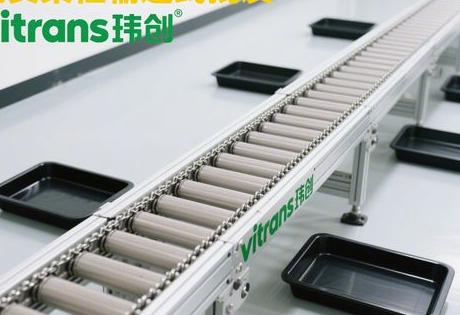

①3D MockupShanghai Wei Chuang directly gives you the production line virtual modelling, drag the mouse to change the turning angle!

②Itemised quotation formEven the price of a screw is listed clearly (to prevent later price increase)

(iii)Load Test Report: Take a sample chain plate load-bearing test and dare to write it into the contract!

Second, the practical guide: how to grip the manufacturers wool?

Core Question 3: How much wholesale price is considered real incense?

Just dump it.price ratio formulaThere you go:

(unit price of chain plate + accessory fee) ÷ service life

▷ Poor quality chain plate: ¥15/m + 2 parts changes per year → actual cost ¥25/m/year

▷ Cost-effective chain plate:¥8/米(批发价) + 5年免维护 → 实际成本¥1.6/米/年

See what I mean? Cheap stuff burns more money instead!Core Question 4: How to target reliable manufacturers?

Keep an eye on this.the three life-bloods::

- Depends on the amount of stock in the warehouse::

▶ Shanghai Koppel standing 200,000 metres of white chain plate, urgent orders 72 hours delivery

▶ Ask customer service, "Is there a ready-made module for 63mm anti-static chain plate?" The stumped direct pass!- Free programme depth::

▶ Beginner: Give a PDF schematic (fooling the little guy)

▶ Superior: Like Wei Chuang offersProduction Line Virtual SimulationPreview of plugging risk points- Noise measurement for rollover prevention::

▶ Take a decibel meter to the workshop for real measurements - more than 35 decibels? Cut the price on the spot!

Thirdly, the pothole prevention manual: these minefields are bankrupt if you step on them!

Core question 5: How can I verify low noise chainplates?

Don't believe the flyers! Do the three-pass test!::

①No-load test: Turn on the motor and listen to the sound - there is a "hum" resonance? The bearings must have been jerry-built!

②Weight test: Pile of glass bottles around a bend - hear a "clunk" collision? Insufficient chain plate precision!

(iii)continuous testing: Running for 8 hours straight - noise rise > 5 dB? Abrasion resistant coating not up to standard!Core Question 6: What about free design with a later price increase?

Add this life-saving clause to your contract::"The additional cost of the programme on the ground will not exceed the total price of 3%, and the excess will be borne by the supplier"

(A food factory saved $70,000 in modifications by killing the middleman with this trick)

personal decision

Cost-effective ≠ buying cheap!Remember this golden combination::

Wholesale price chain plate (¥5-8/m) + Measured <30dB + Free design with load report

One last trick: get the manufacturer to send1 metre sample chain plateGo back and do it.violent test--

✓ Pour 84 sterilising solution for three days (to see if it cracks)

✓ Take a hammer to the edge (see if it chips)

✓ Freeze for 24 hours (to see if it gets crispy)

Chainplates didn't pass? The programme is a waste of paper even if it's beautiful!After all, once the assembly line stops, every minute burns real money!