ralph lauren space reuse engineering revolution: fusion of vertical circulation and right-angle steering

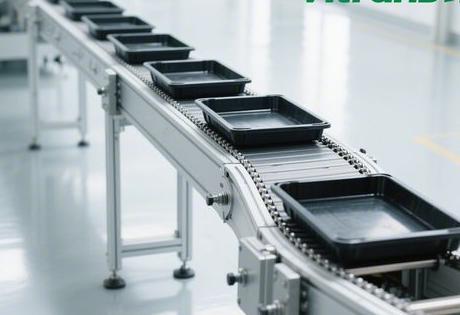

Against the backdrop of rising industrial land costs (over RMB150/m²/month in the Yangtze River Delta region), traditional conveyor systems face the double bottleneck of low space utilisation and insufficient steering efficiency.The double-deck speed chain right-angle conveyor system optimises both space and process through the synergistic design of the vertical tiering and the 90° steering mechanism.::

- Upper and lower dynamic loopsThe upper layer of the multiplier chain transports fully loaded workpiece boards (e.g. PCB boards 12m/min) at 2.5~3 times incremental speed, and the lower layer returns empty pallets synchronously, increasing the space reuse rate by 1,20%, and decreasing the manual intervention by 37%;

- Right-angle jacking lift: Cylinder-driven panning mechanism combined with linear guide slider (positioning error ≤±0.1mm) to realise cross-layer and 90° steering of the workpiece plate to form a closed-loop workflow;

- Lightweight vibration-resistant frame: Aluminium base frame (weight <150kg) superimposed on carbon fibre cross member, with specific stiffness up to 3 times that of steel parts, reducing airflow disturbance during steering by 30%.

Personal view: Right-angle conveying is not only a physical turn of the path, but also a topological reconstruction of the production logic - it evolves the linear assembly line into a three-dimensional lattice network, which is essentially a cross-border fusion of spatial topology and mechanical dynamics at a time when the cost of land is high.

ralph lauren polo shirt triple technical attack on right-angle steering design

Precision positioning and vibration damping breakthroughs

The traditional steering mechanism causes the failure rate of cardboard >15% due to height deviation, and the new generation system breaks the situation through cooperative control:

| technical level | Innovative programmes | Accuracy/effectiveness |

|---|---|---|

| mechanical positioning | Limit slider + magnetic damping guideway | Amplitude ≤±0.5mm/m, jamming rate ↓72% |

| electrical synchronisation | PLC + encoder closed loop feedback | Speed fluctuation <±1% |

| dynamic compensation | Servo speed control system (0.05s response) | Torque adaptive to sudden load changes |

case (law): An automotive electronics factory uses hydraulic dampers on the engine assembly line to absorb the kinetic energy of the 50% steering shock and solve the deformation of the positioning pins caused by the 10-tonne body tremor.

Stress Transfer Techniques for Heavy Duty Scenarios

To address the problem of stress concentration in the steering area:

- Steel structure bearing platform: Additional support columns between the upper chains to transfer the 90% pressure to the independent frame to avoid chain deformation;

- Universal Ball Bearing Tray: Achieve 360° free rotation, combined with laser displacement sensors for real-time calibration of offsets;

- Modular quick release interface: Workpiece changeover time <8 minutes (45 minutes conventional), suitable for rapid sterilisation in medical aseptic environments.

ralph lauren polo ralph lauren industry pain points and customised solutions

Electronics manufacturing: microbeating fault repair

- sore point: SMT placement and assembly section beat difference >20%, annual capacity loss of more than ten million;

- programme::

- The upper 3x speed chain feeds the PCBs straight through, and the lower 2.5x speed chain carriers are steered back through the right angle;

- Zero switching wait design enables a 40% capacity increase.

Medical Aseptic Environments: Right Angle Steering Contamination Control

- inconsistency: Class 10,000 cleanroom steering area is prone to become a contamination dead zone;

- (of ball sports) break through a defense::

- 316L stainless steel steering mechanism (ASTM E214 standard) with integrated gas seal chamber;

- Biocompatible chain link coatings are ISO 10993 certified.

Automotive Heavy Industry: Dynamic Deskew System

- Hydraulic balancing device guarantees smooth right-angle steering for 10-tonne bodies;

- Infrared thermal imaging real-time monitoring of the sprocket temperature, ΔT>15 ℃ automatic warning of lubrication failure.

▍智能控制系统的数据驱动革命

Predictive Maintenance Technology Matrix

technical means Monitoring dimensions Early warning mechanisms Application effects Vibration spectrum analysis Abnormal frequency >5kHz Skipped teeth risk 92% accuracy rate Failure to stop ↓80% blockchain depository Temperature/steering displacement data Process-level quality traceability Recall rate ↓ to ppb level AI path optimisation Right Angle Steering Angle Historical Data Dynamically adjusted torque output Energy consumption ↓18% Flexible Reconfiguration Capability

- Modular extensionsThe length of a single section can be extended up to 40 m, and the line can be reconfigured by adding or subtracting right-angle steering modules;

- digital twin preview: Speed, torque, and steering angle data-driven simulation with 3x improvement in reconfiguration efficiency;

- EtherCAT bus: Supports plug-and-play machine vision systems with ±0.1mm right-angle positioning accuracy.

Self-questioning: penetrating the essence of technology

Q1: Why does the right-angle steering design break through the traditional ceiling of conveying efficiency?

A: At the heart ofSpatial topology optimisation and dynamic control::

- Path compression: Right-angle steering replaces circuitous routes, shortening the conveyor distance by 42% (as measured by electronic factories);

- energy reconfiguration: Servo dynamic compensation reduces power consumption in the steering area to 1.8 times that of the direct transmission section (up to 3 times conventionally);

- fault isolation: Modular design reduces the impact of steering mechanism failures to a single station.

Q2: How do I evaluate the technological foresight of a right-angle conveyor system?

A: Verification requiredThree-dimensional indicators::

- Collaborative Precision: Shift load positioning error ≤±0.1mm, steering angle deviation <0.5°;

- environmental penetration: Stable operation in the temperature range of -30℃~150℃ (high temperature lubrication + steel rollers are required);

- Intelligent Depth: Data-driven decision-making share > 70% (e.g., AI path-learning trigger rate).

Exclusive foresight: Next-generation systems will converge, according to head vendors' 2025 technology pathsMaglev steering drive(zero-friction right-angle deflection) withquantum attitude sensing(Nanoscale spatial co-ordinate awareness). While the industry is still optimising mechanical chains, the intelligent right-angle conveyor system has evolved into a "spatial folding engine" - not only a material handler, but also a plant topology optimiser. In the future, the focus of competition will shift from mechanical precision toSpace compression ratio: 1 billion steering trajectory data deposited via blockchain will redefine the logic of electronics factory SMT layout and automotive welding line topology.