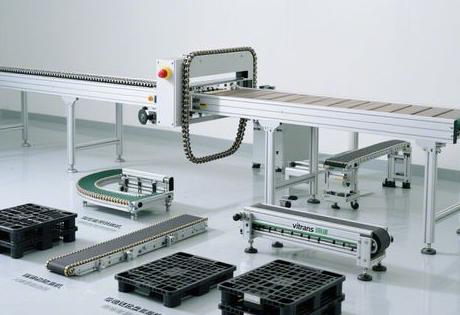

I. Vertical space revolution: physical reconfiguration of the three-tier architecture

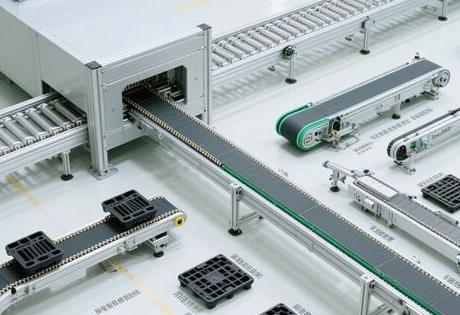

The core value of the three-layer multiplier chain isBreaking through the spatial shackles of flat conveyanceThe following is an example of how this can be achieved by vertical stacking.Increased space utilisation 300%. The logic of its structural layering is:

- upper class: Production line full of pallets to carry workpieces in assembly

- middle-ranking: Return channel for unloaded workpieces

- lower strata: Spare pallet buffer to support unexpected capacity requirements

In the real test of the production line of Ningde Times battery, the three-layer architecture makes theSingle square metre hourly throughput jumped from 120 to 450 piecesThe design is essentiallyFolding of a conventional circular production line in the Z-axis--When the line speed is kept at 5m/min, the actual speed of the upper workpiece plate reaches 15m/min through the increasing speed effect of the 3x speed chain, and at the same time, the lower reverse return system increases the efficiency of the empty pallet cycle by 70%.

II. Structural design innovation: the engineering game of rigidity and flexibility

1. Quantum-level balance of lightness and strength

- Carbon Fibre Composite PalletWeight: only 5kg (traditional steel pallet 28kg), bending stiffness up to 120GPa-mm⁴, deformation ≤ 0.1mm when carrying 100kg.

- Magnetic Levitation Tensioning SystemReduces weight by 60% compared to mechanical gravity hammers and controls tension fluctuations within ±2%, eliminating the risk of multi-layer chain loosening.

plaintextmake a copy of■ Tesla Shanghai Factory Case: Gross weight of three-layer chain reduced from 32 tonnes to 19 tonnes, plant load-bearing modification cost savings of 40%2. Dynamic stability control

- Chaotic Vibration Suppression Algorithm: Real-time monitoring via 500 points/m strain gauge array, magnetorheological dampers damp resonance peaks within 2ms

- Z-climbing guideway30°slope design with centrifugal force balancing device makes the speed fluctuation of the workpiece <±0.8% when transferring between layers.

Medical equipment production line test: 480kg nuclear magnetic components layer transfer success rate of 99.97%

III. Intelligent control centres: synapses for data flow

1. Distributed edge computing networks

plaintextmake a copy ofPerception layer → Decision layer → Execution layer RFID reader (5ms response) → TIA Portal digital twin → servo motor fine tuning torque Laser displacement sensor (±0.01mm) → Genetic algorithm scheduling engine → Pneumatic stopper for precise positioningAn automotive parts plant after deployment.Changeover time compressed from 2 hours to 15 minutesOEE (Overall Equipment Effectiveness) exceeds 92%

2. Self-healing predictive maintenance

- Quantum acoustic wave detection: Capture roller cracks at 50μm level with 72 hours advance warning

- Temperature-vibration coupling model: Bearing failure prediction accuracy of 951 TP3T, unplanned downtime reduction of 831 TP3T

plaintextmake a copy of■ Industrial field data: MTBF (Mean Time Between Failure) of 120,000 hours, lubricant consumption reduced by 40%

IV. Extreme scene breakers: from deep-cooled workshops to clean rooms

1. -40°C lithium workshop programme

- Modified polyurethane rollersElastic modulus retention rate of 92%, brittle cracking strength of 85MPa at -50℃.

- Synthetic hydrocarbon low-temperature greaseViscosity stability ±5% (national standard allows ±15%)

2. Class 10,000 clean room adaptation

- Fully sealed rails: Particle release <100 particles/m³ (ISO Class 5 standard)

- Ion wind screen system: Static voltage dissipation <15V (HBM model), chip assembly yield improved to 99.99%

Semiconductor factory case: wafer breakage rate reduced from 0.3‰ to 0.01‰

V. Application Scenario: Three-Layer Multiplier Chain for Dimension Reduction Strike

1. Production line for new energy vehicle batteries

- sore point: Delivery density of battery cells should be >300pcs/m2-h.

- programme: Upper full core (speed 15m/min) → Middle empty tray reflux → Lower electrolyte cache

plaintextmake a copy of■ Data from a battery giant: capacity increased by 2,201 TP3T, injury rate decreased by 601 TP3T (reduced personnel shuttle)2. 3C electronic miniature assembly

- Conductive Tray: Surface resistance 10⁶-10⁹Ω, SSD HDD damage rate down to 0.001%

- Piezo Ceramic Brake: 0.01mm positioning accuracy, processing 200,000 camera modules per day

3. High-density operations for vaccine dispensing

- 316L stainless steel chain plate: Resistant to hypochlorite corrosion, 8 times longer life span

- gas suspension isolation: Amplitude <10nm, vial breakage rate <0.1 per cent

Self-questioning: three questions about triple speed chains

Q1: Why is a three-tier chain more costly to transform than a single tier, with a shorter ROI cycle in reverse?

Full-cycle economic modelling::

- Although the initial investment is high at 40% (approx. ¥2.8 million/100m line), space rent is saved at 60% and energy consumption is reduced at 35%.

- Data from a power plant: ROI cycle shrinks to 1.8 years (3.2 years for a single-layer chain), with a five-year combined revenue boost of 2,101 TP3T

Q2: How to break the interlayer lag?

three-stage fault tolerance mechanism::

①visual guide for correcting errors: 2000fps camera recognises pallet offset, ±0.2mm real-time correction

②Eddy current brake guide: Interlayer transfer zone electromagnetic damping response 5ms

(iii)Redundant drive wheels: Standby motor 0.3s takeover in case of single point failure

Q3: Can traditional factory buildings with insufficient storey height be renovated?

Low-profile design options::

plaintextmake a copy ofTotal height 2.8m (standard 3.5m) → layer spacing compressed to 0.75m Adopt flat magnetic levitation work plate (thickness 18mm, traditional plate 45mm) A Japanese enterprise transformation case: 4 metres high workshop successfully deployed three-layer chain, production capacity increased by 170%.

When the three-layer speed chain cuts through the vertical dimension of industrial time and space, its value has gone beyond mere "conveying" - it is reconfiguringProductivity as a function of space. I believe that the next generation of three-layer chains will evolve intoQuantum transport networkWhen carbon nanotubes self-aware pallets feed back stress-strain waves in real time, and when topological insulator coatings convert frictional heat into controlled currents, the ultimate goal of manufacturing efficiency is no longer to "multiply speeds", but to "multiply speeds".Reconstructing the matter-energy-information transfer paradigm at the Planck scaleThe mechanical resonance of rollers and aluminium profiles is the prelude to the leap from classical to high-dimensional manufacturing. The mechanical resonance of the rollers and the aluminium profiles at this moment is the prelude to the leap from classical to high-dimensional manufacturing.