In modern automated production systems, theSpeed chain conveyor lines through unique speed increase mechanism and modular design.The system has become the "invisible driver" of efficient operation in the electronics, automotive and home appliance industries. This system integrates mechanical engineering and intelligent control technology, which not only redefines the efficiency of material transfer, but also quietly promotes the innovation of production line design concept.

I. Core Principle: Engineering Wisdom for Speed Stacking

The secret at the heart of the multiplier chain isDifferential design of roller and roller diameters. When the chain is pulled by the drive at a fixed speed (V₁), the rollers at the bottom of the workpiece plate, because their diameter (D) is greater than the diameter of the chain rollers (d), generate an additional speed of rotation (V₂) at the point of contact. The two movements are superimposed to form the total speed of the work plate:

V = V₁ × (1 + D/d)

For example, a 3x chain (D=2d) allows the work plate to move at 3 times the chain speed.

This design cleverlyConverting linear drives into compound motions--Retaining the stable traction of the chain, but also through the roller rotation to achieve "dynamic acceleration", solving the traditional conveyor line efficiency and positioning accuracy is difficult to be compatible with the pain points.

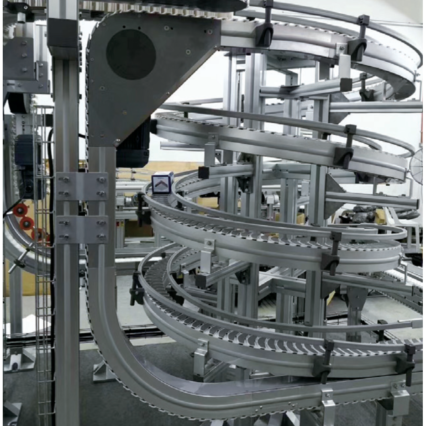

II. Anatomy of a structure: a sophisticated system of modular synergies

The high performance of a Speed Chain conveyor line relies on the precise coordination of five core components:

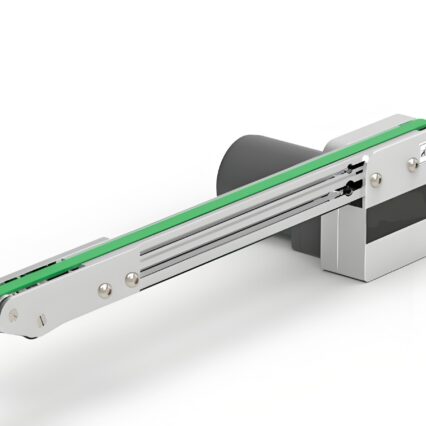

- Multiplier Chain: Engineering plastics or steel roller/roller combination, light load (500kg) to suit different scenarios;

- Rails & Racks: Surface-treated aluminium alloy profiles provide stable support, resist corrosion and reduce friction loss;

- drive unit: Inverter motor to achieve 0.5-8 m/s stepless speed regulation, matching the flexible production beat;

- Positioning control system: Photoelectric sensor + blocker synergy, positioning error is controlled within ±0.5mm;

- Tooling Board Design: The conductive row is connected to the conductive wheel of the wire body to support charged detection and assembly.

-

Third, the performance advantage: beyond the traditional transport breakthroughs

Compared to belt or roller lines, the differentiated competitiveness of the Speed Chain is highlighted by three points:

- Dynamic load capacity: Maximum 2200kg for light loads and up to 4000kg for heavy loads in a single section;

- environmental adaptation: Stable operation in low temperature of -20℃ to high temperature of 80℃ and dusty environment;

- Functionality Extensibility: Horizontal/vertical circulation and multi-station co-ordination by means of jacking translators and indexer modules.

In the case of an automotive plant application, theIncrease capacity by 40% with multi-stage differential control, confirming its scheduling advantages in complex assembly scenarios.

-

IV. Industry applications: penetration from microelectronics to heavy equipment

The flexibility of the multiplier chain allows it to shine in two main areas:

3C Electronics

- On the test line for mobile phone motherboards, a 2.5x speed chain transports precision PCBs at a speed of 5 metres/minute and completes 20 micro-soldering processes with an automatic stop;

- In notebook computer assembly, the static protection type work plate avoids the chip static breakdown, and the yield rate is increased by 15%.

Automotive Manufacturing

- On the engine sub-assembly line, a 3x speed steel roller chain carries 500kg of cylinder blocks, which are accurately positioned to the tightening station;

- New energy vehicle battery pack assembly line, through the multi-layer speed doubling chain to achieve the vertical flow of battery cell-module-pack.

-

V. Technological evolution: integration of intelligence and sustainability

个人观察发现,当前Double Chain Technology正经历三重升级:

- Control Intelligence: PLC system access to IIoT platform, real-time monitoring of chain wear, tension status, predictive maintenance to reduce downtime;

- Material innovation: Carbon fibre composite rollers tested for 60% weight reduction and improved wear resistance over steel components;

- Energy efficiency optimisation: Regenerative braking motor recovers deceleration energy, saving 18% over conventional drives.

Future.Deep synergy with AGVs and robotic armsIt will break through the limitations of linear conveying and build a "dynamic production island" - the work plate is no longer confined to a fixed track, but through intelligent scheduling to realise the flow of the whole plant across the workshop.

VI. Exclusive Perspective: Redefining the Hidden Value of the Multiplier Chain

With most discussions focusing on its efficiency, we may be underestimating the multiplier chain'sstrategic value::

- It is essentiallyData carriers in the physical world: The tooling board ID binds the product's full process parameters and provides real-time mapping for the digital twin;

- Low-cost automation portalThe cost of modifying the original production line is only 1/5 of the cost of a multi-million dollar intelligent production line, making it a pragmatic path for SMEs to enter Industry 4.0.

In the case of a motor factory in WenlingOEE (Overall Equipment Effectiveness) jumped from 63% to 89% by integrating discrete station data through Speed Chain + RFID system.This demonstrates the disruptive potential of "traditional devices + data streams".

Self-questioning: the core questions of the speed chain conveyor line analysis

Q1.Why does the speed of the work plate outstrip the chain itself?

A: The core in the diameter difference design - roller and roller contact, roller rotation of the circumferential speed superimposed on the chain translation speed (V workpiece = V chain + (D / d) * V chain), the formation of 2-3 times the growth rate.

Q2.What scenarios are not suitable for multiplier chains?

A: Ultra-high speed (>20m/min), micron-level positioning, strong acid environment three types of scenes need to be used with caution. At this time, magnetic levitation conveying or precision screw module is more advantageous.

Q3.What are the key maintenance points?

A: Replace the gearbox lubricant in the first three months, and then once a year; check the roller wear and tensioning device every month to avoid positioning drift due to slackness.

With the deepening of modular production, the multiplier chain has evolved from a mere conveyor tool to aCyclic Neural Networks for Intelligent Production Lines--Balancing efficiency and precision in rigidity and flexibility, which is precisely the scarcest competence gene in modern industry.