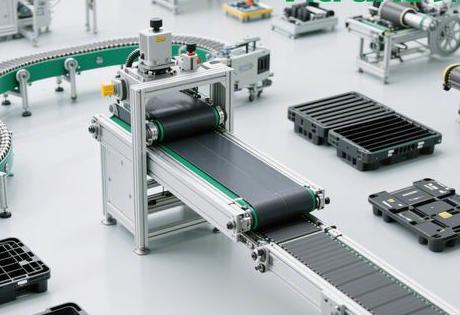

In the wave of transformation of manufacturing to smart, high-densityMiniature double-deck speed chain conveyor lineIt is becoming the "invisible artery" in the field of precision electronics, medical equipment and other high-end fields. Through the unique mechanical structure design, it can multiply the material conveying efficiency in the limited space, which is called the space folding art in industrial engineering.

I. Multiplier chain core technology: mechanical code for speed superposition

The essence of a multiplier chain is aMotion Stacking System--The material conveying speed is higher than the chain's own travelling speed through the difference in diameter between the rollers and the rollers. The core principle can be broken down as:

- Driven by structural differences: The diameter of the roller (D) is larger than the diameter of the roller (d), and when the chain moves with speed ν, the roller rotation generates an additional linear velocity (V₂ = D/d × ν)

- Velocity synthesis formula: Total speed of the work plateV = ν × (1 + D/d)

For example, when D/d=2 (3x chain speed), the plate speed can be up to 3 times the chain speed. - Friction compensation mechanism: Practical applications due to frictional losses in the guideway.Increase in speed is compensated by high-precision manufacturing (tolerance ≤ 0.1 mm) and automatic lubrication system.Ensures speed stability

Miniaturisation further challenges the application of this principle - in a compact structure with a reduced pitch of 25.4mm, the need for aPrecision roller chains with ball bearingsReduces friction, and byPrecise control of the ν value by variable frequency motors(0.3-1.5m/s adjustable) to adapt to the conveying rhythm of miniature workpieces.

II. Double-storey architecture: revolutionary use of vertical space

The traditional single-deck conveyor line occupies a large area and has a low return efficiency, while the innovation of the miniature double-deck multiplier chain is:

- Dynamic partition design

- upper production layer: Carrying workpiece boards for assembly, width 250-400mm (for materials such as micro PCBs)

- lower return layer: Empty boards return channel articulated by lifts, space utilisation increased by 40%

- Circulatory system synergy

- Jacking and panning mechanism: Pneumatic cylinder drive + guide axis positioning (repeatability ±0.1mm) for inter-layer transfer of tooling boards

- closed loop control system: PLC real-time co-ordination of hoist and conveyor line speeds to avoid backflow congestion.

personal viewpoint: The double-layer design appears to increase complexity byVertical dimension to solve the contradiction of production line extensionIn the case of an electronics SMT shop, this structure enabled a 10 metre line length to achieve the equivalent of an 18 metre single layer line. In the case of an electronics SMT shop, the structure enables a 10-metre line length to achieve the equivalent capacity of an 18-metre single-layer line, demonstrating the value of "space folding".

III. Adaptability breakthroughs in precision manufacturing scenarios

The differentiating advantages of miniature double-deck doubler chains are particularly prominent in the field of precision manufacturing:

- High precision transport of micro loads

adoptionEngineering plastic roller + aluminium alloy trackCombination (hardness HRC40-45), in the load ≤ 50kg to maintain the operating noise <65dB, while avoiding scratching the surface of precision workpiece. - Bandwidth compatibility

Workplace Board IntegrationConductive Wheels and Slip LinesIn-line power supply for test stations (12V-48V DC) - Nanoscale stop control

pass (a bill or inspection etc)Pneumatic stopper (response time ≤ 0.5 sec) with photoelectric sensorLinkage, so that the micro-mounted parts positioning error ≤ 0.3mm

IV. Key challenges and countermeasures in engineering realisation

Under the dual constraints of miniaturisation and bilateration, three major technical bottlenecks need to be overcome:

- Chain tension balancing

adoptionTwin-axis independent tensioning system(spring type + tension sensor monitoring), instead of the traditional single-axis tensioning, to ensure that the difference between the two sides of the chain droop ≤ 2% pitch, to avoid micro-wire body run-off - Thermal deformation compensation

For high-temperature environments (e.g., chip curing processes), choose theCarbon fibre composite rails(Thermal expansion coefficient ≤ 0.8×10-⁶/K), 5 times higher deformation resistance than aluminium alloy. - Particulate pollution prevention and control

riseEnclosed Lubrication Module(oiling every 500 hours), using high temperature chain oil (100 ℃ viscosity ≥ 46mm ² / s), to prevent oil contamination of the clean room

Exclusive data reference: Empirical measurements show that in a medical microfluidic chip production line, a miniature double-layer doubled chain ofOverall Equipment Effectiveness (OEE) of 89.7%The new line is a 23% improvement over the conventional conveyor line, mainly due to reduced downtime and improved line changeover efficiency.

V. Intelligent Evolution: From Mechanical Conveyance to Data Hub Evolution

The future value of the miniature double-layer speed chain is moving from a "transport carrier" to a "data interface":

- State-Aware Networking

embeddingPressure/Temperature Sensor GroupReal-time monitoring of chain health (e.g. sudden change in tension >20% triggers alarm) - digital twin (Twin) collaboration

pass (a bill or inspection etc)Speed-load relationship model(V=ƒ(μ,Q)) predicts energy efficiency bottlenecks and dynamically adjusts drive power. - Modular Expansion Interface

reserveMechanical/electrical double coupling positionSupports rapid integration with AGV connectivity or RFID readers.

personal experienceWhen the mechanics become the data nodes, the value of the multiplier chain goes beyond the "transport" itself. A semiconductor line retrofit project I worked on proved this.Failure prediction by analysing roller wear data reduces unexpected downtime by 70%-- a metaphor for the deep integration of physical systems and digital intelligence that is reshaping the logic of manufacturing.

Core Q&A about Miniature Double Decker Speed Chain Conveyor Line

Q1: What are the core advantages of the miniature double-layer doubling chain?

A: InHigh speed delivery and precise control in a small footprint.It is especially suitable for precision industries such as electronics and medical, as it enhances the space utilisation of more than 40% through vertical circulation design, and supports micron-level positioning at the same time.

Q2: What is the special design of the double-layer structure compared with the traditional single-layer line?

A: The key is in theDynamic triage mechanism::

- High speed conveyance of tooling boards on the upper level by means of a 3-fold chain (roller diameter/roller diameter ≈ 2).

- Lower level configuration of jacking and panning machine + return track to form a closed loop

- Synchronised control of inter-layer transfer timing via PLCs

Q3: Which scenarios should be prioritised for this option?

A: Three types of typical scenarios:

- SMT placement line with limited workshop space but need to expand capacity.

- Precision instrument assembly line requiring electrical strip testing of tooling boards

- Aseptic Medical Device Packaging Line with High Cleanliness Requirements

Q4: What is the main direction of technology evolution?

A: Tofour-dimensional integrationDevelopments: nano-precision of machinery (e.g. piezoelectric ceramic drives), dynamisation of digital models (real-time twins), intelligent energy management (inverter energy savings > 30%), standardisation of module interfaces (plug-and-play extensions) - ultimately a neural network for flexible manufacturing.