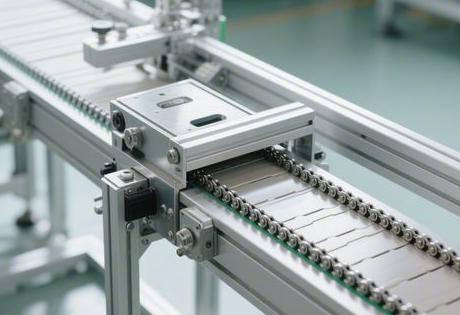

In a new energy vehicle battery factory in Suzhou, up to 200 metres of silver track, carrying half a tonne of heavy battery modules of the work plate is 15m/minute speed glide - seems to be a uniform movement behind, hidden so that the production efficiency to improve 300%The Mystery of Geometric Growth。自动化倍速链已超越传统输送设备范畴,成为Intelligent Manufacturing Systems的dynamic neural networkIt is the fusion of mechanical precision design and digital control technology that reshapes the production logic of modern industry.

I. Technology kernel: a revolution in speed in millimetres

The core mystery of the multiplier chain isSynergy of the two-stage movement system. When the motor drives the inner chain roller (diameter d) at the base speed V₁, the outer chain roller (diameter D) triggers an additional linear velocity V₂ = (D/d) x V₁ under the pressure of the workpiece plate, which ultimately results in aTotal V = V₁ x (1 + D/d)The multiplier effect. This design allows the workpiece to be conveyed at three times the speed (e.g. 18m/min) in the unloaded section, and then precisely reduced to 2m/min when it arrives at the assembly area by means of a laser sensor and a pneumatic stopper, achieving aDynamic speed control.

Key Innovation Breakthrough Points.

- Diameter Ratio Precision Control: By adjusting the D/d ratio (commonly 1.5 to 3 times the speed), the efficiency is increased while keeping the chain wear low. For example, when D=2d, the speed of the work plate can be up to 3 times of the chain speed.

- Optimisation of frictional energy consumptionRolling friction is used instead of sliding friction between the rollers and the work plate, reducing energy consumption by 40% and avoiding vibration damage to precision electronic components.

- Environmental adaptation enhancementSpecial alloy steel chain has a life span of 3 years under 85% humidity and 50℃ environment, which is 400% higher than ordinary chain.

II. System Composition: From Mechanical Transmission to Intelligent Hubs

A complete multiplier chain system isSymbiosis of precision mechanics and digital technologyIts modular design supports flexible adaptation to diverse industrial scenarios.

1. Evolution of the hardware architecture

- Bearing innovationLight load type adopts engineering plastic rollers (load ≤ 2200kg), heavy load type is equipped with steel rollers (load ≤ 4000kg), and the pressure is dispersed by increasing the contact area of the rollers.

- Leadership RevolutionSpecial aluminium profile guide rail (width 250-900mm adjustable) with self-cleaning roller structure, dust channel ≤ 2mm, completely solve the risk of jamming.

- Drive DistributedThe 600m line body is divided into 12 independent drive sections, and the jacking and shifting mechanism automatically diverts the flow in case of a single point of failure, reducing downtime losses by 87%.

2. Intelligence in control systems

- Dynamic Beat Adjustment: PLC programming real-time adjustment of blocking timing, the same production line mixed production of high-end products (station stop 120 seconds) and basic models (stop 60 seconds), switching time tends to be close to zero.

- digital twin prediction: Workpiece board embedded RFID chip, synchronous mapping of kiln temperature profile, air tightness data and other parameters, 14 days in advance warning of equipment failure.

III. Industry empowerment: a practical programme to break manufacturing pain points

▋ Automotive manufacturing: a model for heavy-duty precision assembly

In the chassis production line of a brand of electric car, the multiplier chain carries 500kg battery packs to completion:

- millimetre positioningLaser sensor controls ±0.5mm stopping accuracy, ensuring that the wiring harness insertion and connection pass rate is increased to 99.6%.

- heat resistanceResistant to 120°C coating chain for continuous operation and thermal radiation environment in the battery pack gluing process.

▋ Electronic Semiconductors: Micron Clean Conveying

In the chip packaging plant, the multiplier chain system is designed through triple purification:

- Static elimination roller: Avoid particle adsorption

- Enclosed rails: Isolation of external dust

- Oil-free bearings: Eliminate lubrication contamination

Maintains ISO Class 3 cleanliness in the workshop and reduces defect rate by 67%

▋ New energy batteries: a new paradigm for energy efficiency balance

An innovative application in one of Ningde Times' factories:

- Gravitational potential energy recovery: Generation of electricity using the descending section, with an auxiliary power supply self-sufficiency rate of 181 TP3T

- Carbon Fibre Workplace PanelReduced weight 30% reduces chain load and saves 240,000 kWh of electricity per year

IV. Future evolution: the leap to ultra-flexible manufacturing systems

Double Chain Technology正经历三大范式变革:

1. Reconfiguration of human-computer collaboration

Workers receive instructions while wearing AR glassesSynchronised delivery of tooling materials by robotic armsIncreased assembly efficiency by 40% and zero error rate (measured at Bosch Suzhou plant).

2. Green manufacturing integration

- Photovoltaic-Storage Power: Rooftop Solar Panels Directly Supplying Speed Chain Motors, a Wujiang Factory's Energy Share Reaches 41%

- Bio-based lubricants: Biodegradable Chain Oil Reduces Hazardous Waste Emissions by 3 Tonnes Per Year

3. Code-free flexible configuration

Drag-and-drop interface to reorganise workstation processes, supporting line switching of 3 product models per hour (already implemented in the Bowie and 2024 prototypes)

The essence of the evolution of the multiplier chain is to transform the physical growth rate of the machinery into the value growth rate of the data flow - when the diameter of the roller increases by 0.1mm each, it brings not only 13% efficiency enhancement, but also a quantum leap in the decision-making accuracy of the entire manufacturing system.

Ask Yourself: Core Concerns with Speed Chain Technology

▋ Why is the actual speed often limited to 15m/min?

Balance of safety and precision: Inertial displacement of the work plate exceeds 2mm at >15m/min, affecting precision assembly. But bySegmented speed control strategy(18m/min in non-operating area + 2m/min in assembly area), the comprehensive efficiency is still up to 3 times of the traditional line.

▋ How do ceramic dust environments safeguard operations?

Enclosed rail + self-cleaning rollersComposition of double protection: dust channel width ≤ 2mm, Jiu Mu Nanan factory 100,000 times cycle test zero jamming.

▋ Does a single point of failure lead to total paralysis?

Distributed drive solution splits the production line into independent drive segments, and the jacking and shifting mechanism automatically diverts the flow when a single segment fails, reducing the loss of downtime of a line body in Wrigley by 87%.

▋ How can SMEs lower the barrier to use?

Modular leasing mode (such as Flywheel da solution): basic frame + 750W inverter motor + adjustable width aluminium profile, the initial investment is compressed to 20% of the traditional solution.