During the manufacturing of electronic products, theroller conveyorIt plays an important role. It is mainly used for the automatic transmission of materials, and can adapt to the high standard requirements of electronic manufacturing, with the characteristics of anti-static, high precision and flexible adjustment.

01

Main application scenarios

PCB Production Segment

-Transferring printed circuit boards to mounters, reflowers, etc.

-Buffer zones between different processes to balance the pace of production

-Safe transport of cut circuit boards to the test station

Assembly of electronic components

-Conveys precision parts such as mobile phone screens and cameras

-Safe transport of lithium batteries and chips with specialised equipment

-Handling heavy parts such as heat sinks

Product Testing Session

Semi-finished products are sent to different test stations in sequence.

-Automatic identification of defective products with inspection equipment

-Automatically sorts conforming products from those that need to be returned for repair.

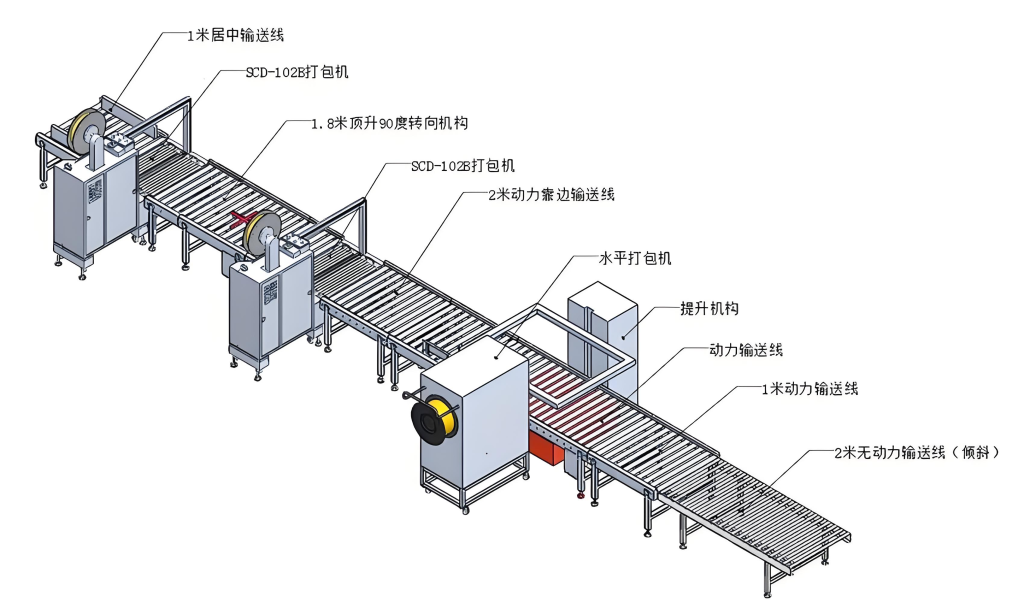

Packaging and Warehousing

-Connecting packaging equipment such as sealing and labelling

-Automatically adjusts the conveyor width according to the product size

-Fast sorting of different products and accessories

02

Key technical features

-Anti-static design to protect sensitive electronic components

-Adapted to the closed structure of the clean room

-Positioning accuracy up to 0.1 mm

-Flexible height and width adjustment

-Smooth operation and reduced vibration

03

Practical application cases

-Mobile phone production line:Automatic loading and unloading of the motherboard, the fastest cycle is completed in 5 seconds.

-Semiconductor plants:Safe wafer transport in a clean environment

-Notebook production line:Simultaneous handling of different product sizes

From circuit boards to finished mobile phones, roller conveyor lines are like the "blood circulation system" of electronics manufacturing, connecting each production link in an intelligent way, greatly improving the efficiency and quality of electronics manufacturing. With the progress of technology, it can be expected that its application will continue to expand.